Coated controlled release fertilizer and preparation method thereof

A technology of coating controlled-release fertilizer and coating is applied in the field of chemical compound fertilizer, which can solve the problems of short duration of controlled-release coating of coated controlled-release fertilizer, and achieve the effects of convenient operation, prolonging controlled-release time and prolonging fertilizer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

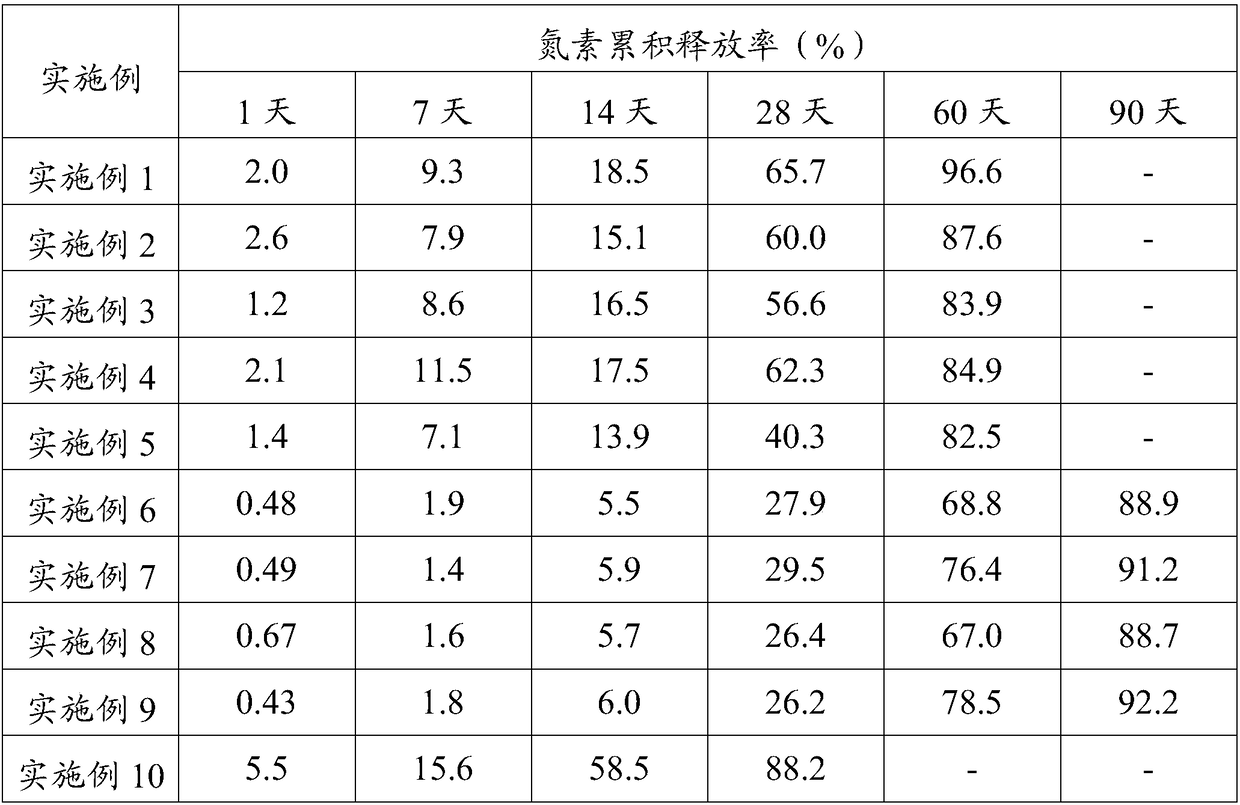

Examples

preparation example Construction

[0031] The preparation method of the above-mentioned coated controlled-release fertilizer comprises the following steps:

[0032] S10. Heating the fertilizer core to 60° C. to 80° C., and the fertilizer core is nitrogen fertilizer.

[0033] In one of the embodiments, the nitrogen fertilizer is selected from at least one of urea and urea-based compound fertilizer.

[0034] In one embodiment, the time for heating and raising the temperature of the fertilizer is 20 minutes to 40 minutes.

[0035] Specifically, in this embodiment, the heat treatment of the fertilizer is carried out in a drum device. The rotating speed of the drum device is set at 2r / min~15r / min.

[0036] S20. Mix the isocyanate, polyol, curing catalyst and additives uniformly in a mixer to obtain a mixture.

[0037] S30 , coating the fertilizer core with the mixture at 60° C. to 80° C.

[0038] In one embodiment, the coating treatment is carried out in a drum device, the coating treatment time is 10 minutes to...

Embodiment 1

[0046] Select 970g of urea as the fertilizer core, the urea particle size is 2.0mm-4.8mm, put it in the drum device, the rotating speed of the drum device is set to 12r / min, heat treatment for 20min until the temperature of nitrogen fertilizer is 60°C; weigh 21g Toluene diisocyanate, 9g of glycerol, 0.03g of curing catalyst triethanolamine and 0.2g of additive diaminophenylphosphate, mixed evenly, added to the drum device, heated at 60°C for 20min to obtain coated controlled-release fertilizer.

Embodiment 2

[0048] Select 970g of urea as the fertilizer core, the particle size of urea is 2.0mm-4.8mm, put it in the drum device, the rotating speed of the drum device is set to 10r / min, heat treatment for 30min until the temperature of nitrogen fertilizer is 70°C; weigh 28g Polyphenyl polymethylene polyisocyanate, 15g of castor oil polyol, 0.03g of curing catalyst dibutyltin dilaurate and 0.4g of additive caproyl hydroxamic acid, mix well and add to the drum device, at 70 ℃ Under heating for 15 minutes, the coated controlled-release fertilizer is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com