Magnesium-based composite material as well as preparation method and application thereof

A composite material, magnesium-based matrix technology, applied in the fields of biomedical engineering and biomedical materials, can solve the problems of difficult to meet precision medicine, lack of tissue regeneration, and difficult to solve the problem of continuous and stable release of loaded drugs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

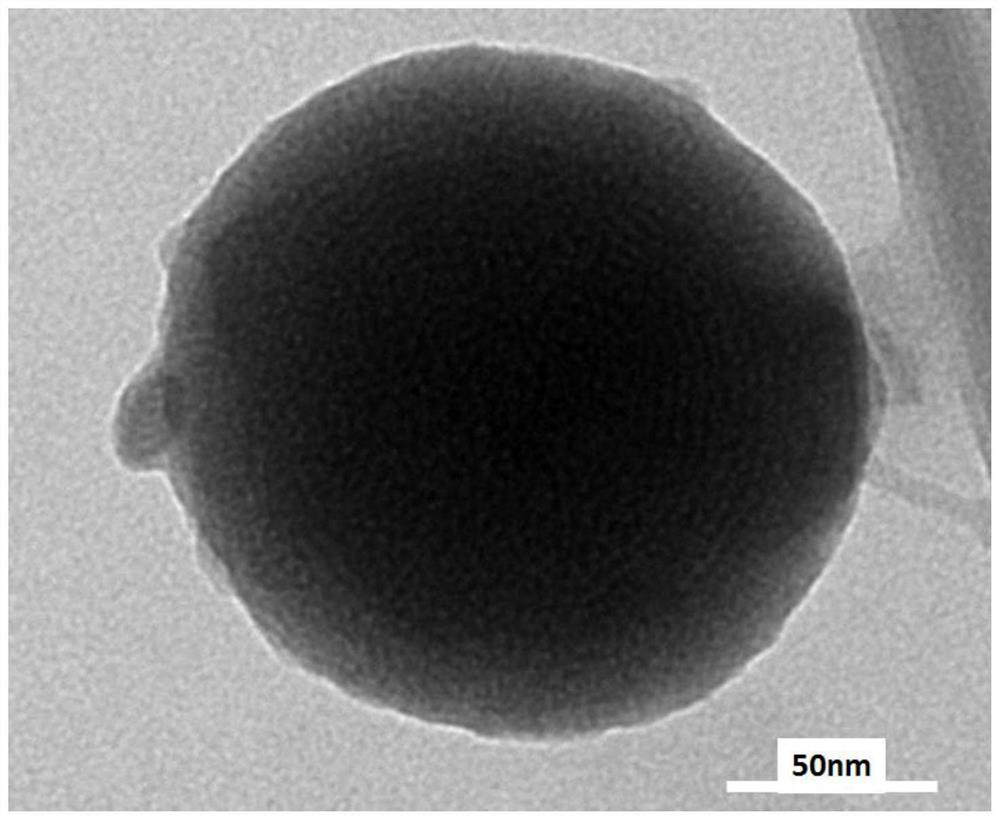

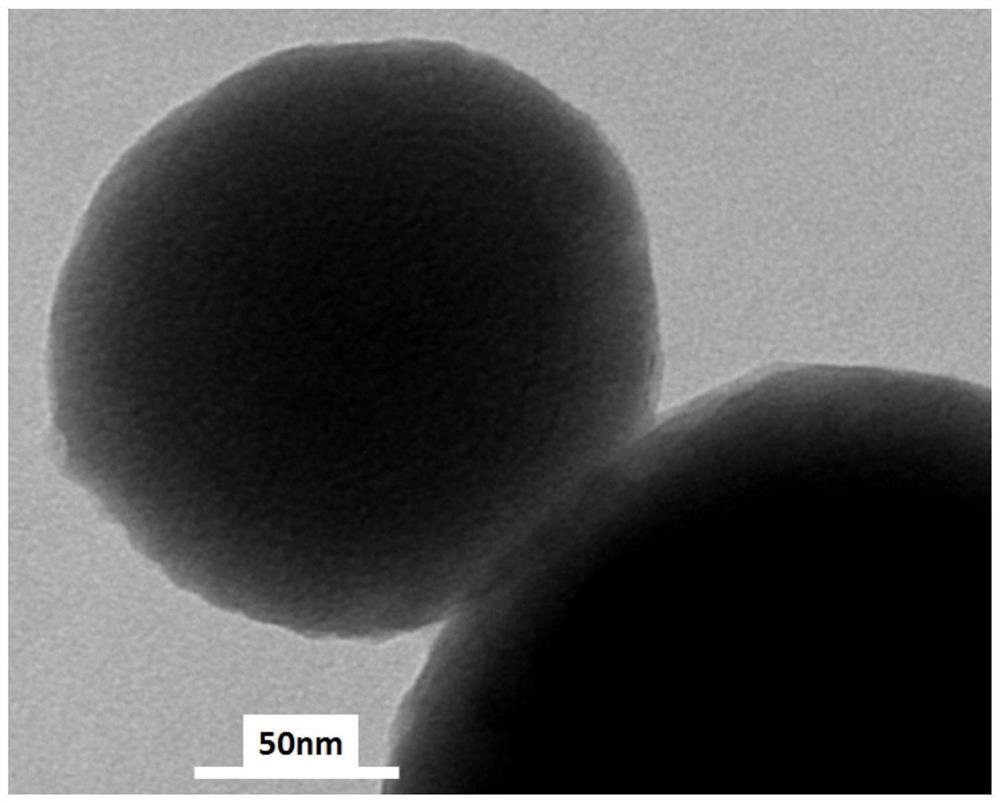

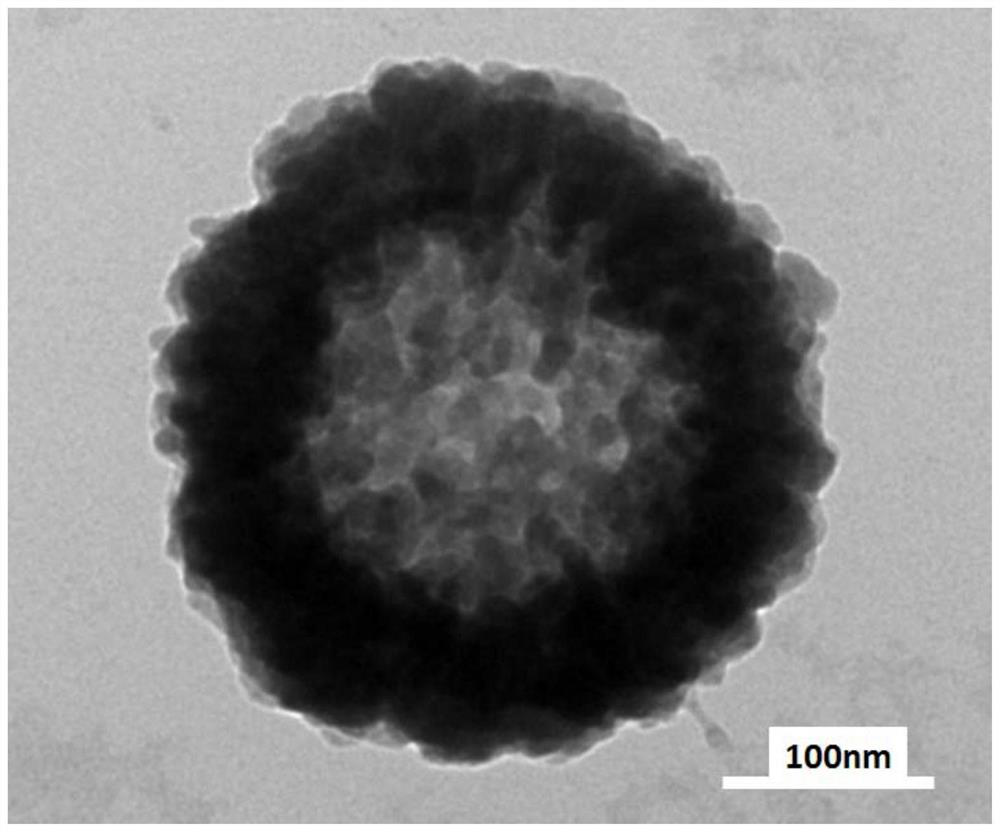

Image

Examples

Embodiment 1

[0123] In this embodiment, a magnesium-based composite material is prepared, and the specific process is as follows:

[0124] A1. Use 800-mesh SiC sandpaper to polish the magnesium-based material (magnesium content > 99%), then rinse with deionized water for 2 minutes, dehydrate with ethanol for 4 minutes, and then immediately dry in air;

[0125] A2. Under mechanical stirring, mix 18g Na 3 PO 4 12H 2 O (about 47mM) and 3g Ca(OH) 2 Dissolve (approximately 40.5mM) in 1L aqueous solution, and mechanically stir for 6 minutes to obtain an electrolyte;

[0126] A3. Using the constant current mode, the magnesium-based material obtained in step S1 is treated with the plasma electrolytic oxidation method; specifically, in the plasma electrolytic oxidation treatment, the current frequency is 2000 Hz, the duty cycle is 20%, the positive voltage is 500 V, and the temperature is 80°C, under stirring, first with 0.03A / cm 2 The current density was treated for 25s, and then 0.8A / cm 2 T...

Embodiment 2

[0136] In this embodiment, a magnesium-based composite material is prepared, and the specific process is as follows:

[0137] A1. Use 280-mesh SiC sandpaper to polish the magnesium-based material (magnesium content > 99%), then rinse with deionized water for 2 minutes, dehydrate with ethanol for 4 minutes, and then immediately dry in air;

[0138] A2. Under mechanical stirring, 10g Na 3 PO 4 12H 2 O (about 26mM) and 1g Ca(OH) 2 (about 13.5mM) was dissolved in 1L aqueous solution, and mechanically stirred for 3 minutes to obtain an electrolyte;

[0139] A3. Using the constant current mode, the magnesium-based material obtained in the plasma electrolytic oxidation treatment step S1; specifically, in the plasma electrolytic oxidation treatment, the current frequency is 2000Hz, the duty cycle is 20%, the positive voltage is 500V, and the temperature is 60°C , under stirring, first at 0.01A / cm 2 The current density was treated for 60s, and then 1.5A / cm 2 The current density w...

Embodiment 3

[0149] In this embodiment, a magnesium-based composite material is prepared, and the specific process is as follows:

[0150] A1. Use 1000-mesh SiC sandpaper to polish the magnesium-based material (magnesium content > 99%), then rinse with deionized water for 2 minutes, dehydrate with ethanol for 4 minutes, and then immediately dry in air;

[0151] A2. Under mechanical stirring, mix 15g Na 3 PO 4 12H 2 O (about 39mM) and 2g Ca(OH) 2 (about 27mM) was dissolved in 1L aqueous solution, and magnetically stirred for 5 minutes to obtain an electrolyte;

[0152] A3. Using the constant current mode, the magnesium-based material obtained in the plasma electrolytic oxidation treatment step S1; specifically, in the plasma electrolytic oxidation treatment, the current frequency is 2000Hz, the duty cycle is 20%, the positive voltage is 500V, and the temperature is 75°C , under stirring, first at 0.02A / cm 2 The current density was treated for 30s, and then 1A / cm 2 The current density ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com