A kind of preparation method of flame-retardant polyurea elastomer coating

A polyurea elastomer and flame-retardant technology, which is applied in the field of preparation of flame-retardant polyurea elastomer coatings, can solve the problems of reduced mechanical properties, difficulty in controlling the viscosity of component B, and hindering combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a preparation method of polyurea elastomer coating, comprising the following steps:

[0036] (1) Mix the dehydrated siloxane polyether glycol with diisocyanate and diluent uniformly in the reaction kettle, and then react at 80~95℃ for 2~4h to obtain component A;

[0037] (2) Mix the dehydrated amino-terminated polyether and dehydrated amine chain extender with organic aluminum hypophosphite, polytetrafluoroethylene, ammonium polyphosphate, dipentaerythritol and additives in the reaction kettle. Stir at 120° C. for 1-2 h to obtain component B.

[0038] According to the present invention, in order to optimize the reaction efficiency, the present invention also dehydrates the raw materials under reduced pressure before the reaction. The pressure is 0.02~0.1MPa, and the time is 1~3h.

[0039]According to the present invention, in order to optimize the reaction efficiency, the present invention also conducts decompression dehydration on ...

Embodiment 1

[0044] The content of each raw material in component A and component B in this example is shown in Table 1.

[0045] (1) dehydrate 40 parts by weight of siloxane polyether diol at a temperature of 110° C. and a pressure of 0.05 MPa for 2 h, and then dehydrate the dehydrated siloxane polyether diol with 55 parts by weight of 4, 4'-MDI and 5 parts by weight of DOP were uniformly mixed in the reaction kettle, and then reacted at 90° C. for 3 hours to obtain component A;

[0046] (2) 50 parts by weight of D-2000 and 30 parts by weight of Ethacure300 were dehydrated for 1.5 hours at a temperature of 110° C. and a pressure of 0.05 MPa, and then dehydrated D-2000, dehydrated Ethacure300 and 8 parts by weight were dehydrated Organic aluminum hypophosphite, 1 part by weight of polytetrafluoroethylene, 8 parts by weight of ammonium polyphosphate, and 3 parts by weight of dipentaerythritol are uniformly mixed in a reaction kettle, and stirred at 90° C. for 1.5 hours to obtain component B...

Embodiment 2

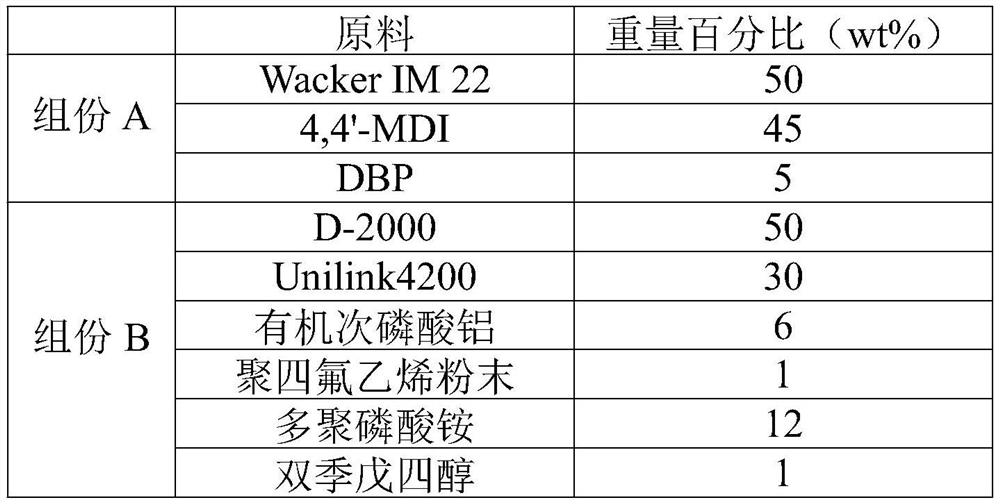

[0050] The content of each raw material in component A and component B in this example is shown in Table 2.

[0051] (1) dehydrate 50 parts by weight of siloxane polyether diol at a temperature of 110° C. and a pressure of 0.02 MPa for 2 h, then dehydrate the dehydrated siloxane polyether diol with 45 parts by weight of 4, 4'-MDI and 5 parts by weight of DBP were mixed uniformly in the reaction kettle, and then reacted at 85°C for 3 hours to obtain component A;

[0052] (2) 50 parts by weight of D-2000 and 30 parts by weight of Unilink4200 were dehydrated for 2 hours at a temperature of 110°C and a pressure of 0.05MPa, and then dehydrated D-2000, dehydrated Unilink4200 and 6 parts by weight of organic Aluminum hypophosphite, 1 part by weight of polytetrafluoroethylene, 12 parts by weight of ammonium polyphosphate, and 1 part by weight of dipentaerythritol are mixed uniformly in a reaction kettle, and stirred at 100° C. for 1 hour to obtain component B.

[0053] Table 2: Conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com