Method for preparing needle coke

A technology for needle coke and coal tar, which is applied in the petroleum industry, hydrotreating process, and hydrocarbon oil treatment. Reduced harshness, dramatic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

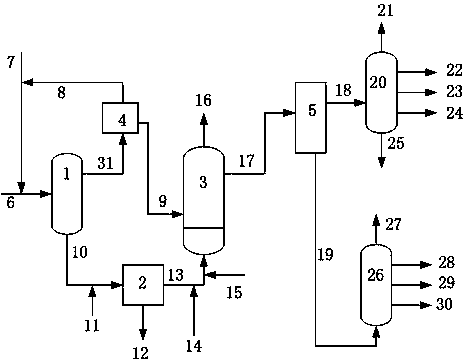

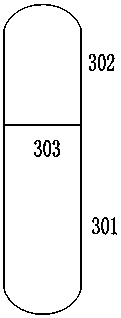

Method used

Image

Examples

Embodiment 1

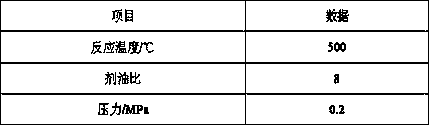

[0048] The properties of coal tar and oil-based raw materials used in the test are shown in Table 1. The processing ratio of the two raw materials is 1:1 (mass ratio). The process conditions of supercritical extraction are shown in Table 2. The process conditions of the pretreatment unit are shown in Table 3. The ebullated bed reactor Catalyst properties are shown in Table 4. The light components generated by the ebullated bed reaction are returned to the pretreatment unit as a pretreatment agent. The mass ratio of the pretreatment agent to coal tar raw material is controlled to be 0.2, and the remaining light components are sent to the catalytic cracking unit and the ebullated bed reactor. , coking unit and catalytic cracking unit reaction conditions refer to Table 5, 6, 7. See Tables 8 and 9 for the properties of needle coke and product distribution of catalytic cracking units.

Embodiment 2

[0050] Embodiment 2 has the same raw material properties as in Example 1, and the light components generated by the fluidized bed reaction are partially returned to the pretreatment unit as a pretreatment agent, and the mass ratio of the pretreatment agent to coal tar raw material is controlled to be 0.4, and the remaining light components enter the catalytic cracking unit , see Table 3 for the pretreatment conditions, see Tables 5, 6, and 7 for the reaction conditions of the ebullated bed reactor, coking unit and catalytic cracking unit. See Tables 8 and 9 for the properties of needle coke and product distribution of catalytic cracking units.

Embodiment 3

[0052] Embodiment 3 has the same properties as the processing raw materials in Embodiment 2, except that the supercritical extraction process conditions are different, and the process conditions of other processing units are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com