Wiredrawing lubricating oil, preparation method thereof and drawing method of bonding wire

A technology of lubricating oil and bonding wire, applied in the field of microelectronic packaging and interconnection, which can solve the problems of influence, increase of material hardness, unfavorable bonding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a preparation method of the above wire drawing lubricating oil, comprising: heating the lubricating oil, adding graphene powder, and ultrasonic treatment to obtain the wire drawing lubricating oil.

[0029] Wherein, the temperature of the heating is preferably 35° C. to 50° C.; the graphene powder is the same as described above, and will not be repeated here; the frequency of the ultrasonic treatment is preferably 2000 to 3000 HZ; the time of the ultrasonic treatment is preferably 20-60 min, more preferably 30-50 min, and more preferably 30-40 min; during the ultrasonic treatment, the temperature is preferably maintained at 35°C-50°C.

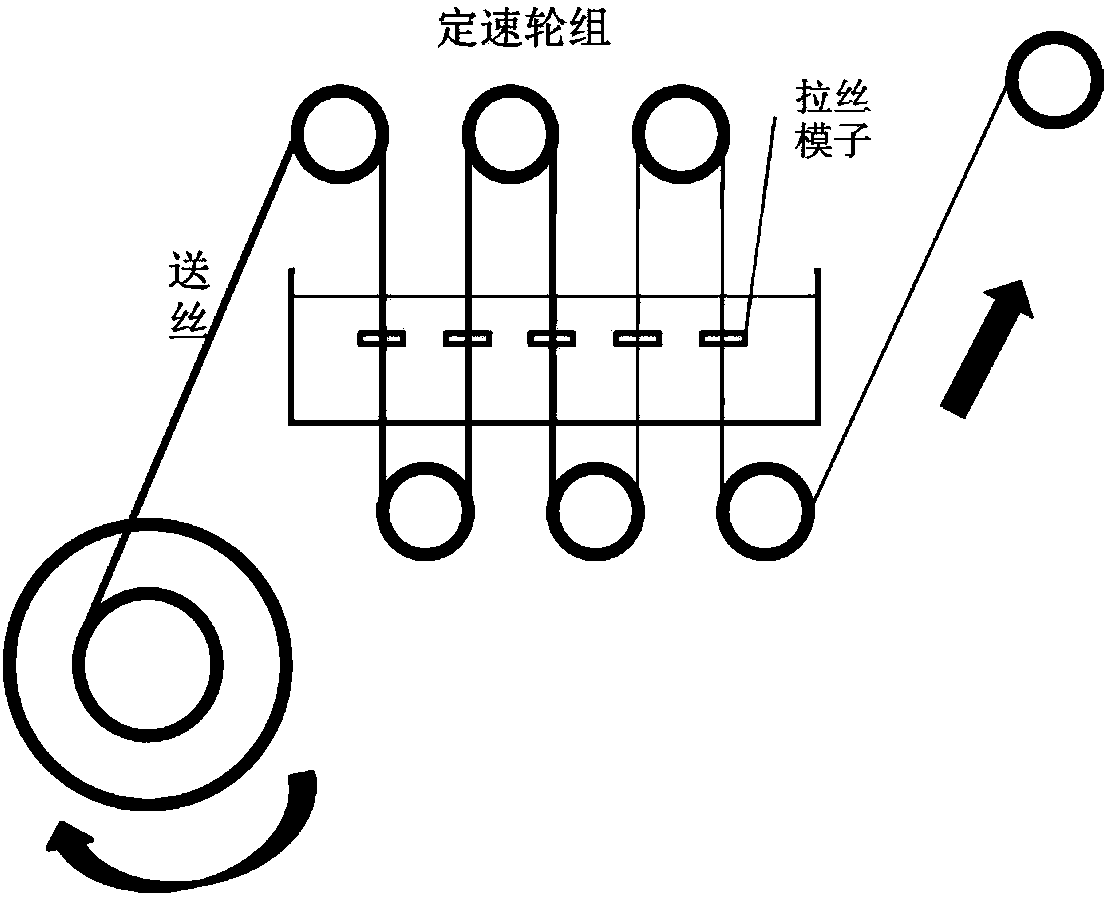

[0030] The present invention also provides a bonding wire drawing method, comprising: covering the drawing die with wire-drawing lubricating oil, and then drawing the metal wire to obtain bonding wire; the wire-drawing lubricating oil includes lubricating oil and graphene powder body.

[0031] In the ...

Embodiment 1

[0044] 1.1 The main components are 28% of No. 7 engine oil, 25% of triethanolamine oleate, 12% of sodium petroleum sulfonate, 3% of Turkish red oil, 4% of polyvinyl butyl ether, 26% of water, and 2% of other components for lubrication Heat the oil to 35-50°C and keep stirring.

[0045] 1.2 Add graphene powder to the stirring lubricating oil to obtain a liquid with a graphene powder mass percentage concentration of 5%. The diameter of the graphene powder is about 2-10 μm, the average thickness is less than 20 nm, and the carbon content is greater than 90.0%.

[0046] 1.3 Seal the above liquid and place it under ultrasonic conditions for half an hour, wherein the temperature of the liquid is kept between 35-50°C during the ultrasonic process to obtain wire drawing lubricating oil.

[0047] 1.4 Add wire drawing lubricating oil into the lubricating oil tank of the wire drawing module, then place the module completely in the middle of the oil tank, use the rotation and stirring char...

Embodiment 2

[0050] 2.1 The main components are 28% of No. 7 engine oil, 25% of triethanolamine oleate, 12% of sodium petroleum sulfonate, 3% of Turkish red oil, 4% of polyvinyl butyl ether, 26% of water, and 2% of other components for lubrication Heat the oil to 35-50°C and keep stirring.

[0051] 2.2 Add graphene powder to the stirring lubricating oil to obtain a liquid with a graphene powder mass percentage concentration of 10%. The graphene powder has a diameter of about 2 to 10 μm, an average thickness of less than 20 nm, and a carbon content greater than 90.0%.

[0052] 2.3 Seal the liquid above and place it under ultrasonic conditions for half an hour, wherein the temperature of the liquid is kept between 35°C and 50°C during the ultrasonic process to obtain wire drawing lubricating oil.

[0053] 2.4 Add the super-drawing lubricating oil into the lubricating oil tank of the wire drawing module, then place the module completely in the middle of the oil tank, and draw the copper wire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com