Degrading bacteria JN5 for petroleum hydrocarbons in oily sludge and its application

A technology of JN5, degrading bacteria, applied in the field of bioremediation, can solve the problems of no investment in large-scale application, cumbersome cultivation process operation, large influence of environmental factors, etc., and achieve the effect of reducing complex steps, optimizing soil microbial system, and enhancing biological activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

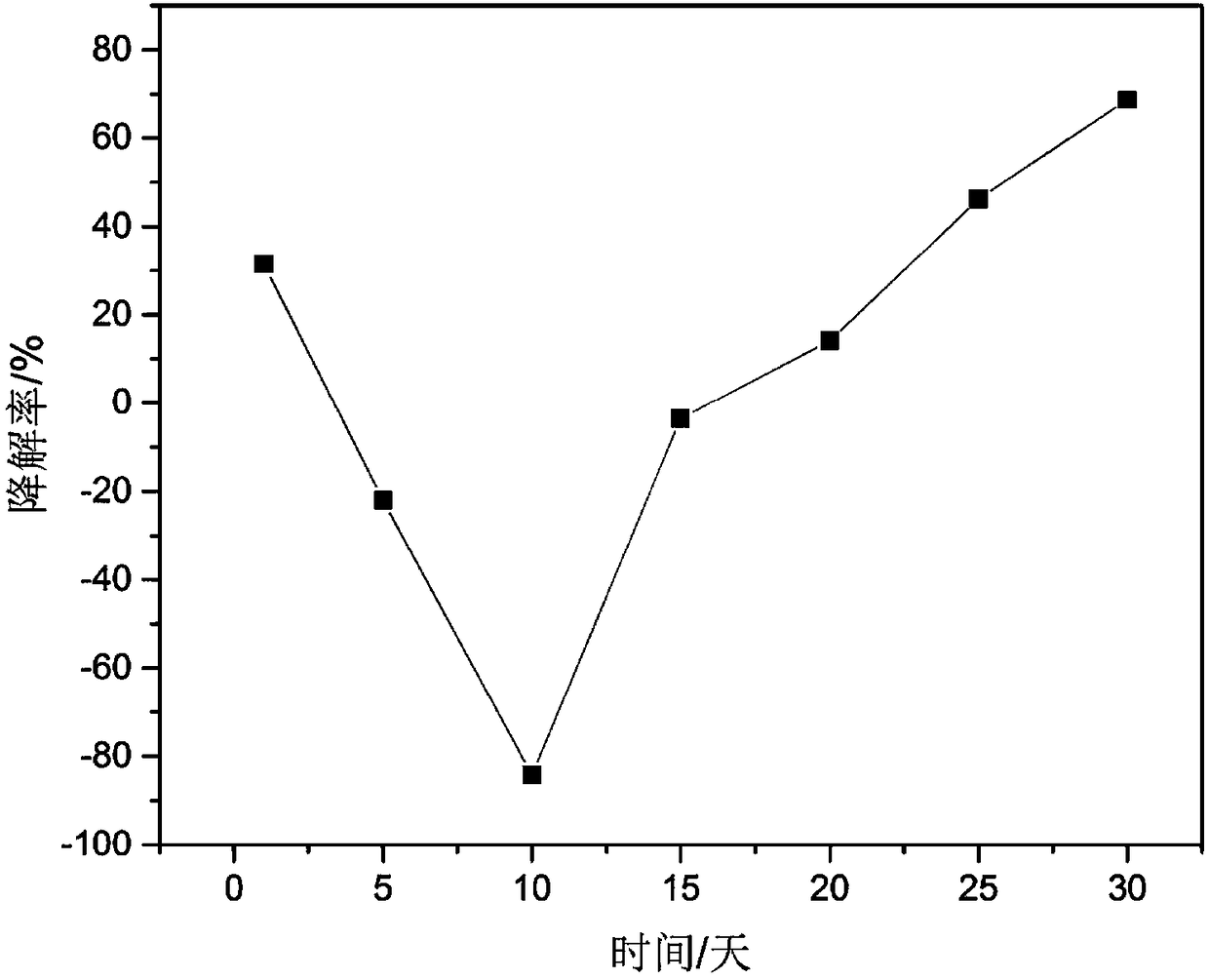

[0059] Example 1: Degradation and repair test of oily sludge in Liaohe Oilfield

[0060] Oily sludge from Liaohe Oilfield was taken, air-dried and ground, passed through a 1mm sieve, and set aside. Pick a single colony in sterilized LB liquid medium, seal it with a gas-permeable sealing film, place the Erlenmeyer flask in a shaker at 120 rpm, and activate at 30°C for 24 hours. Weigh 40 g of the above-mentioned air-dried, ground and sieved oily sludge, add 10% inoculation amount of Pseudomonas stutzeri JN5 activated bacterial solution with OD600=1, adjust the water-to-soil ratio to 2:5 with distilled water, and seal it with a breathable sealing film. All Erlenmeyer flasks were placed in a constant temperature incubator at 30°C for static cultivation, samples were taken every 5 days, and the content of total petroleum hydrocarbons in the oily sludge was measured with an infrared spectrophotometer. The degradation curve is shown in the attached image 3 shown. It can be seen fr...

Embodiment 2

[0064] Example 2: Degradation effect of Pseudomonas stutzeri JN5 on petroleum hydrocarbons in oily sludge at different pH values

[0065] Oily sludge from Liaohe Oilfield was taken, air-dried, ground, and passed through a 1mm sieve. Weigh 40 g of the above oily sludge in a conical flask, and use dilute H 2 SO 4and NaOH to adjust the pH of the soil to 1, 3, 5, 7, 9, 11, respectively, according to the inoculation amount of 10%, add the activated bacterial solution of Pseudomonas stutzeri JN5 with OD600=1, and adjust the water-soil ratio to 2:5 with distilled water, and use Breathable parafilm closure. All the Erlenmeyer flasks were placed in a constant temperature incubator at 30°C for static cultivation and samples were taken after 25 days, and the total petroleum hydrocarbon content in the oily sludge was determined by an infrared spectroscopic oil analyzer. The degradation effects of strain Pseudomonas stutzeri JN5 on petroleum hydrocarbons in oily sludge under different p...

Embodiment 3

[0066] Example 3: Degradation effect of Pseudomonas stutzeri JN5 on petroleum hydrocarbons in oily sludge at different temperatures

[0067] Oily sludge from Liaohe Oilfield was taken, air-dried, ground, and passed through a 1mm sieve. Weigh 40 g of the above oily sludge into an Erlenmeyer flask, add 10% inoculum amount of Pseudomonas stutzeri JN5 activated bacterial solution with OD600=1, adjust the water-to-soil ratio to 2:5 with distilled water, and seal it with a breathable sealing film. The Erlenmeyer flasks were placed in constant temperature incubators at 10°C, 15°C, 20°C, 25°C, 30°C, 35°C, 40°C, 45°C, and 50°C for static culture, and samples were taken after 25 days. Spectrophotometer was used to determine the total petroleum hydrocarbon content in oily sludge. The degradation effects of strain Pseudomonas stutzeri JN5 on total petroleum hydrocarbons in oily sludge at different temperatures are as follows: Figure 5 shown. Depend on Figure 5 It can be seen that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com