Method of purifying electrolytic aluminium flue gas and recycling aluminum resources by means of aluminum ash of electrolytic aluminum

A technology for electrolytic aluminum and aluminum recycling, applied in chemical instruments and methods, separation methods, aluminum sulfur compounds, etc. problems, to achieve the effect of reducing costs, equipment investment and operating costs, and running clean.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

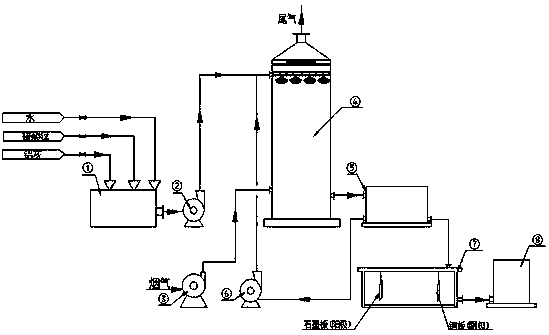

[0027] Embodiment 1: The device used in this embodiment is as figure 1 As shown, it includes a slurry tank 1, a slurry pump 2, a blower 3, a spray tower 4, an oxidation tank 5, a circulation pump 6, an electrolytic cell 7, and a recovery tank 8; The material pump 2 is connected, the outlet of the slurry pump 2 is connected with the upper inlet of the spray tower 4, and the two sides of the lower part of the spray tower 4 are respectively connected with the blower 3 and the oxidation pond 5, and the bottom of the oxidation pond 5 is provided with an aeration pipe, and the oxidation pond 5 The inner wall is provided with a pH detector, and the two water outlets of the oxidation tank 5 are respectively connected with the circulating pump 6 and the electrolytic cell 7. The pool 8 is connected, and a filtering device is provided in the recovery pool 8, wherein the diameter of the spray tower 4 is 3.5m and 8 meters high. Use this device to purify electrolytic aluminum flue gas and ...

Embodiment 2

[0031] Embodiment 2: the device used in this embodiment and the method of operation are the same as embodiment 1, and the difference is that the mass percentages of aluminum ash, manganese sulfate, and water in the gained desulfurization slurry are respectively 18%, 0.1%, and 81.90%, and its desulfurization, The defluorination efficiency and the recovery efficiency of the alloy concentrate are shown in Table 1.

Embodiment 3

[0032] Embodiment 3: The device and operation method used in this embodiment are the same as in Embodiment 1, the difference is that the flue gas flow rate is 4.8 m / s, and the concentration of sulfur dioxide is 200 mg / m 3 , its desulfurization, defluorination efficiency and recovery efficiency of alloy concentrate are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com