Tin alloy electroplating solution

A technology of electroplating solution and tin alloy, which is applied in the field of tin alloy electroplating solution, and can solve problems such as easy occurrence of tin whiskers and short circuit between two adjacent pins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

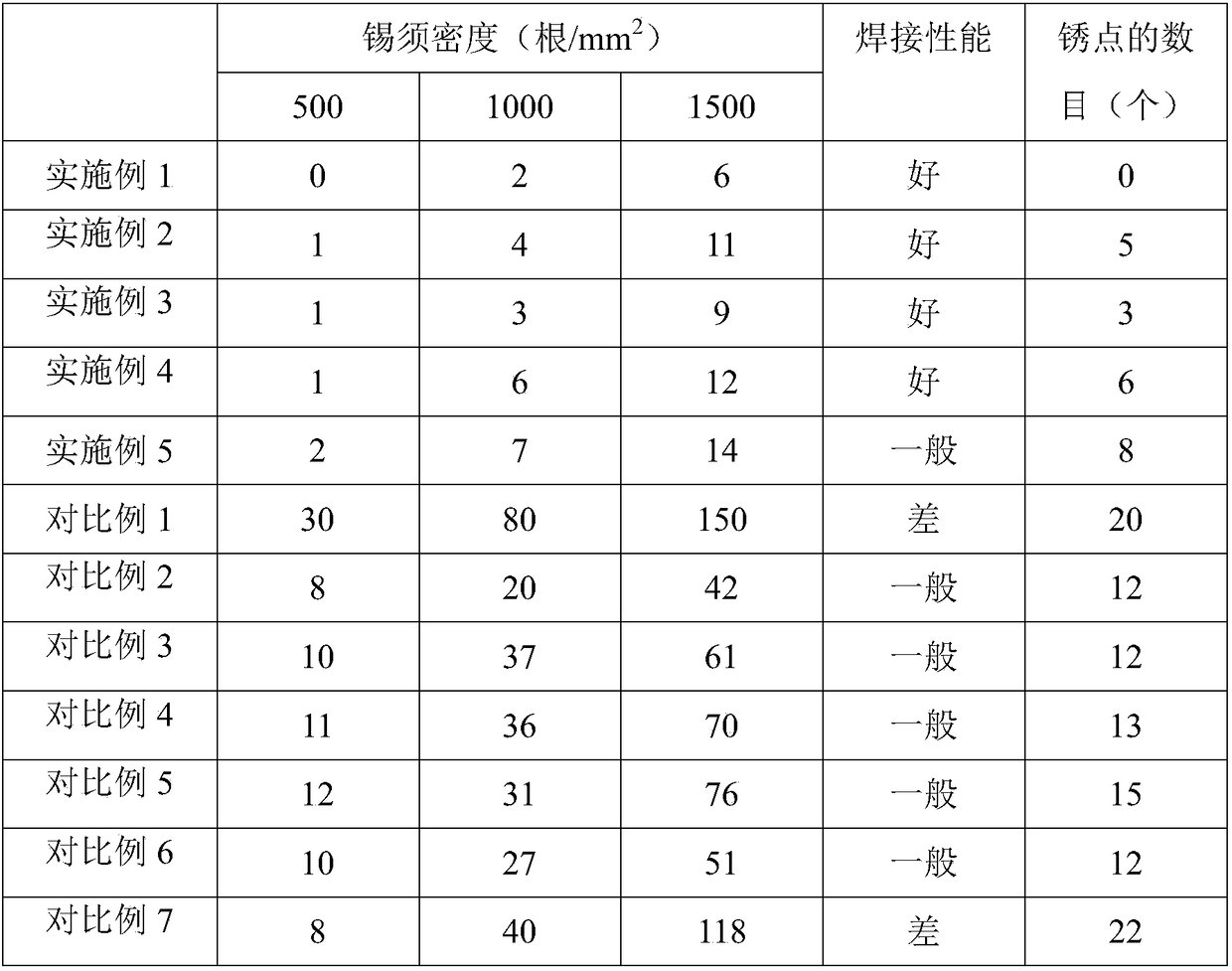

Examples

preparation example Construction

[0033] The preparation method of described mercapto chitosan comprises the following steps:

[0034] Add chitosan, 1-hydroxybenzotriazole, and distilled water into the reactor, stir well, then add 2-mercapto-4-methyl-5-thiazoleacetic acid, 1-(3-dimethylaminopropyl )-3-ethylcarbodiimide hydrochloride, use 1mol / L sodium hydroxide to bring the pH of the reaction solution to 5, react at room temperature for 4h, add absolute ethanol, filter, dry under reduced pressure at 60°C for 10h, grind, Stored at low temperature at 5°C; the weight ratio of the chitosan to the 1-hydroxybenzotriazole and the distilled water is 1:0.7:30; the chitosan to the 2-mercapto-4-formazol The weight ratio of base-5-thiazoleacetic acid is 1:3.6; the 2-mercapto-4-methyl-5-thiazoleacetic acid and the 1-(3-dimethylaminopropyl)-3-ethyl carbon The molar ratio of diimine hydrochloride is 1:1.05; the weight ratio of the chitosan to the absolute ethanol is 1:10.

[0035] Chitosan has strong complexation and adsor...

Embodiment 1

[0064] The tin alloy electroplating solution includes organic mixed acid, organic tin salt, organic silver salt, complexing agent, reducing agent, stabilizer, refiner, brightener, deionized water; calculated by weight, 1000 parts of deionized water , 350 parts of organic mixed acid, 80 parts of organic tin salt, 2 parts of organic silver salt, 100 parts of complexing agent, 45 parts of reducing agent, 60 parts of stabilizer, 10 parts of refiner, 8 parts of brightener, 6 parts of surfactant share;

[0065] Wherein, the complexing agent is 2,4-dithiobiuret, N-methylguanidinoacetic acid, mercaptochitosan, and the 2,4-dithiobiuret and the N-methylguanidine Glycolic acid, the weight ratio of described mercapto chitosan is 1:0.24:0.72, and the preparation raw material of described mercapto chitosan comprises 2-mercapto-4-methyl-5-thiazole acetic acid, chitosan; The organic The mixed acid is citric acid and p-aminobenzenesulfonic acid, and the weight ratio of the citric acid to the ...

Embodiment 2

[0070] The tin alloy electroplating solution includes organic mixed acid, organic tin salt, organic silver salt, complexing agent, reducing agent, stabilizer, refiner, brightener, deionized water; calculated by weight, 1000 parts of deionized water , 350 parts of organic mixed acid, 80 parts of organic tin salt, 2 parts of organic silver salt, 100 parts of complexing agent, 45 parts of reducing agent, 60 parts of stabilizer, 10 parts of refiner, 8 parts of brightener, 6 parts of surfactant share;

[0071] Wherein, the complexing agent is 2,4-dithiobiuret, N-methylguanidinoacetic acid, mercaptochitosan, and the 2,4-dithiobiuret and the N-methylguanidine Glycolic acid, the weight ratio of described mercapto chitosan is 1:0.5:0.3, and the preparation raw material of described mercapto chitosan comprises 2-mercapto-4-methyl-5-thiazole acetic acid, chitosan; The organic The mixed acid is citric acid and p-aminobenzenesulfonic acid, and the weight ratio of the citric acid to the p-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com