A kind of heavy metal ion filter paper and preparation method thereof

A technology of heavy metal ions and filter paper, which is applied in the separation method, pulp beating method, filter paper, etc., can solve the problems of high cost and difficulty in the manufacture of adsorption materials, and achieve easy control, popularization and promotion, industrialization, and simplified treatment process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

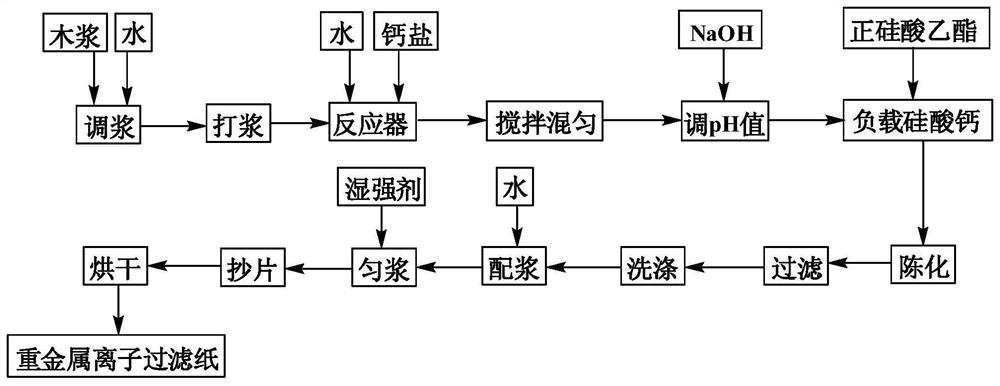

Method used

Image

Examples

Embodiment 1

[0031] (1) Take 150kg of coniferous wood pulp and add water to make a slurry with a concentration of 5.0% by mass, beat on a ZDC beater, beat with a light knife for 1.0h, beat with a medium knife for 3h, and beat with a heavy knife for 1.5h, a total of 5.5h. The amount of slurry was determined to be 8.8g, and the beating degree was 90°SR;

[0032] Beat the hardwood pulp under the same conditions, and measure the amount of hanging pulp to be 9.0g, and the degree of beating is 92 ° SR;

[0033] (2) 100 g of softwood pulp wet slurry beaten in step (1) is added to a 1500 mL three-necked bottle, diluted with water to a fiber mass percentage of 0.4%, fully stirred for 2 h, and then 10.15 g of calcium nitrate tetrahydrate is added, After stirring and dissolving, continue to stir for 1.5h, then add solid NaOH to adjust the pH to 10.1; then slowly add 10.85g of ethyl orthosilicate with a mass fraction of 99.0%, continue to react at room temperature for 4h after dripping, and stand for ...

Embodiment 2

[0040] (1) Take 150kg of hardwood pulp and add water to prepare a slurry with a mass percent concentration of 4.5%, beat on a ZDC beater, beat for 1.5 hours with a light knife, 2.5 hours with a medium knife, and 1 hour with a heavy knife, for a total of 5 hours. The amount of slurry was determined to be 8.5g, and the degree of beating was 89°SR;

[0041] Make coniferous wood pulp by the same condition, measure and hang pulp amount to be 8.3g, beating degree is 87 ° SR;

[0042] (2) Take 112g of hardwood pulp wet slurry beaten in step (1) and add it to a 1500mL three-necked bottle equipped with a constant pressure dropping funnel and mechanical agitation, dilute with water until the fiber mass percentage is 0.5%, and fully stir 1h, then add 5.10g of calcium nitrate tetrahydrate, stir to dissolve and continue to stir for 1h, then add solid NaOH to adjust the pH to 9.50; then slowly add 4.54g of orthosilicate ethyl ester with a mass fraction of 99.0%, continue at room temperature...

Embodiment 3

[0045] (1) Take 150kg of coniferous wood pulp and add water to make a slurry with a mass percentage concentration of 4.75%, beat on a ZDC type beater, beat with a light knife for 1.0h, beat with a medium knife for 2.5h, and knock with a heavy knife for 1.5h, a total of 5.0h . The amount of slurry was determined to be 8.8g, and the beating degree was 90°SR;

[0046] Beat the hardwood pulp under the same conditions, and the measured pulping amount is 8.9g, and the degree of beating is 89 ° SR;

[0047] (2) Get 105.3 g of softwood pulp wet slurry beaten in step (1) and join in a 1500 mL three-necked bottle equipped with a constant pressure dropping funnel and mechanical agitation, add water to dilute to a fiber mass percentage of 0.45%, fully Stir for 1.5h, then add 7.60g of calcium nitrate tetrahydrate, stir to dissolve and continue to stir for 1.5h, then add solid NaOH to adjust the pH to 10.10; Continue to react at room temperature for 3.5 hours, let stand and age for 18 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com