Cellulose-loaded porous calcium silicate filter material for heavy metal ion filtration and preparation method thereof

A technology of porous calcium silicate and heavy metal ions, which is applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., and can solve the problems of filter materials that cannot intercept heavy metal ions, nanofiltration, ultrafiltration and microfiltration Problems such as the inability to separate, achieve the effect of facilitating popularization and industrialization, broadly promoting application value and application prospects, and expanding use methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

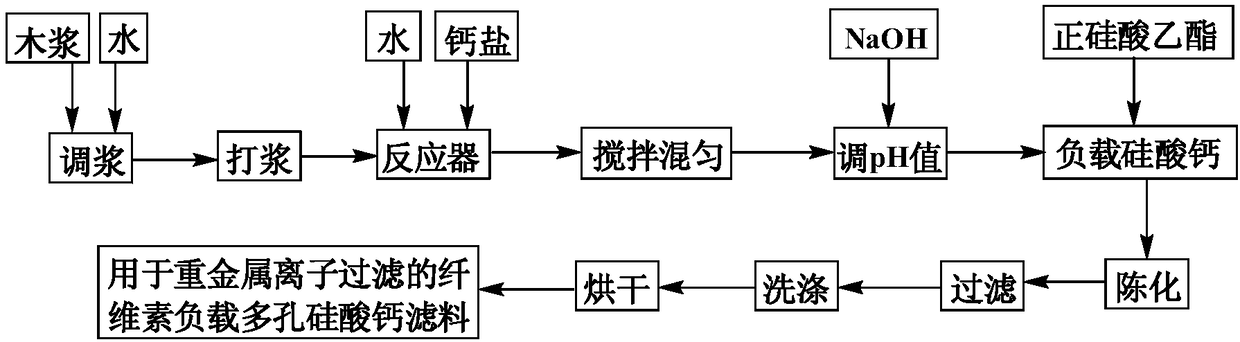

Method used

Image

Examples

Embodiment 1

[0029] (1) Take 150kg of coniferous wood pulp and add water to make a slurry with a concentration of 5.0% by mass, beat on a ZDC beater, beat with a light knife for 1.0h, beat with a medium knife for 3h, and beat with a heavy knife for 1.5h, a total of 5.5h. The measured pulping amount is 8.8g, and the degree of beating is 91 ° SR.

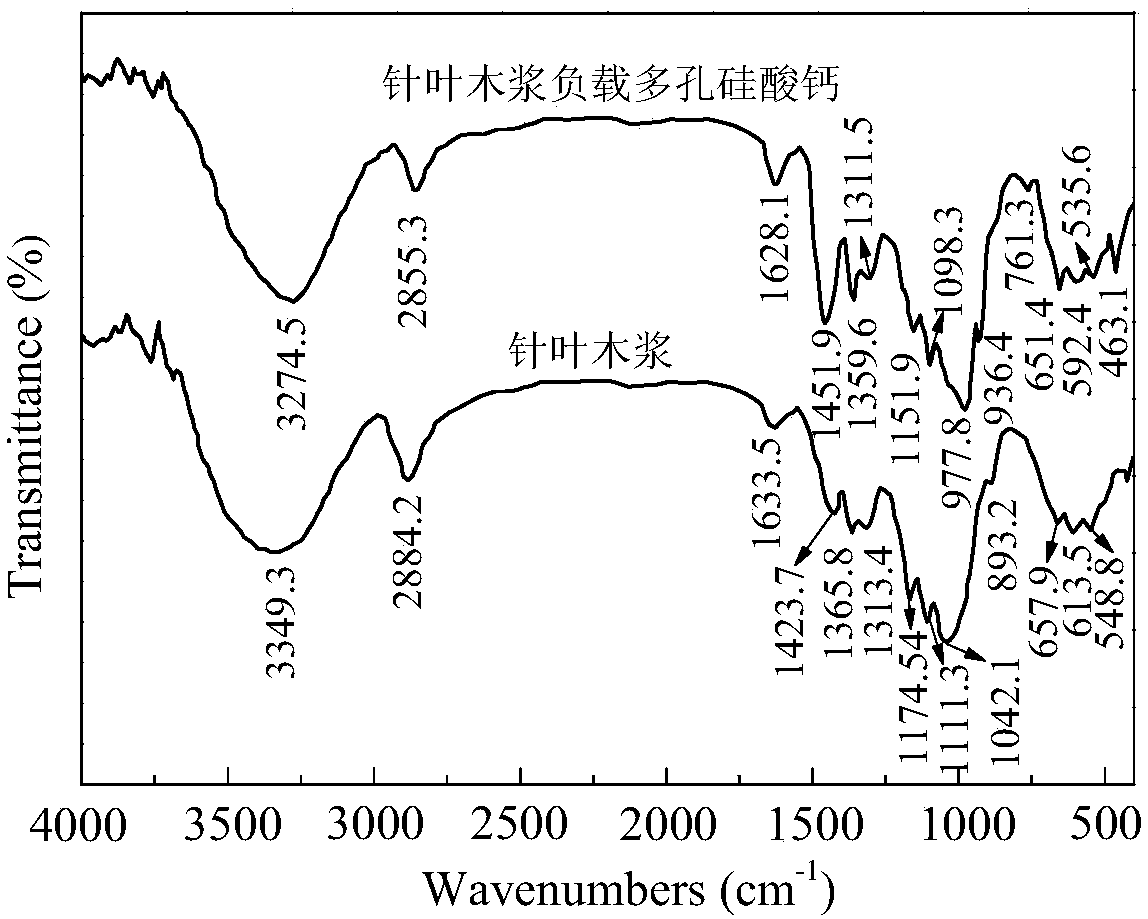

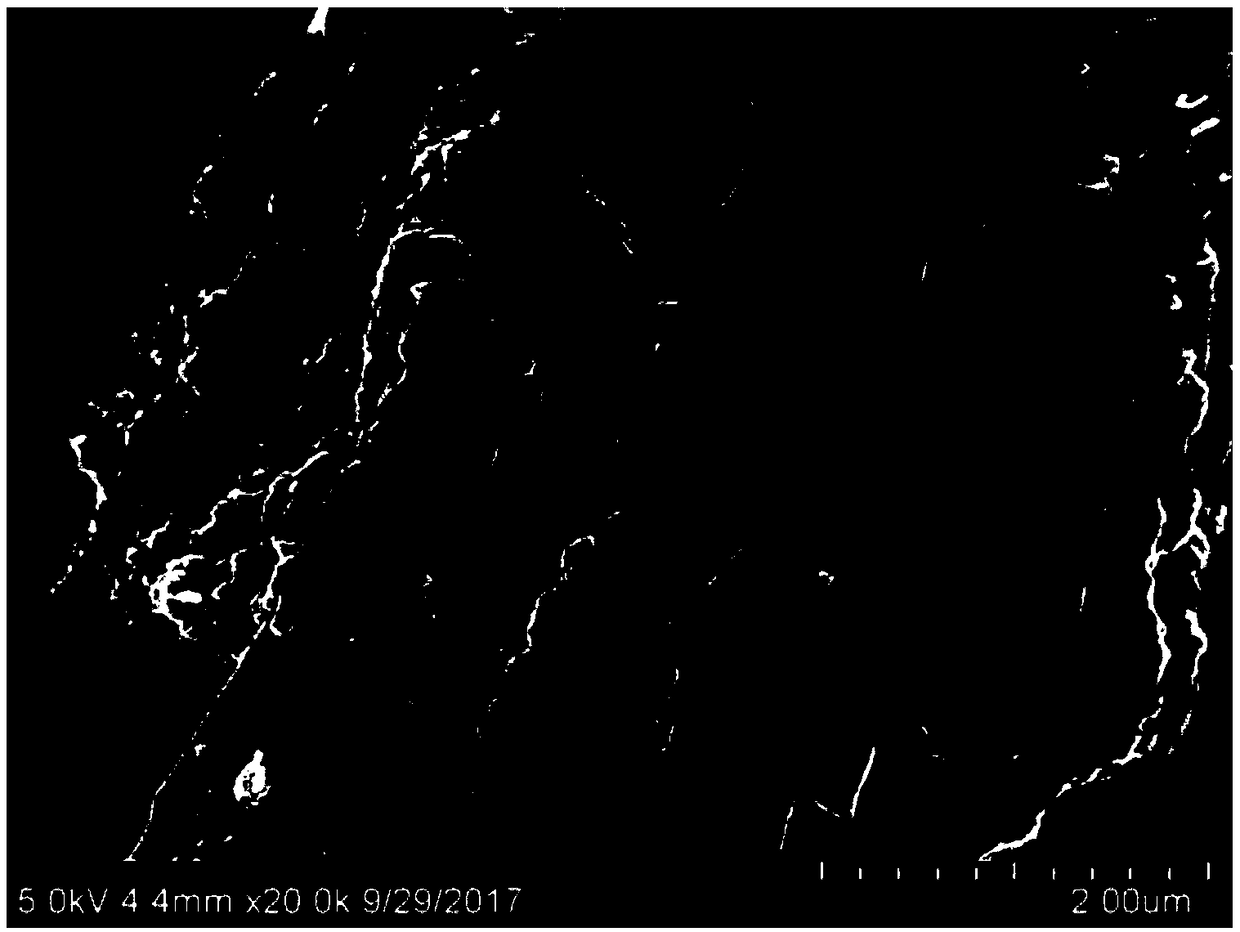

[0030] (2) Take 100 g of the wet slurry beaten in step (1) and add it to a 1500 mL three-necked bottle, add water to dilute to a fiber mass percentage of 0.4%, stir thoroughly for 2 hours, then add 10.15 g of calcium nitrate tetrahydrate, and stir to dissolve Then continue to stir for 1.5h, then add solid NaOH to adjust the pH to 10.1; then slowly 10.85g of tetraethyl orthosilicate with a mass fraction of 99.0%, continue to react at room temperature for 4h after the drop is completed, and leave it to age for 24h; filter, use Washed with distilled water 5 times, placed in a vacuum oven at 60° C. and dried to constant weight to obtain 9.73 g of cell...

Embodiment 2

[0032] (1) Take 150kg of hardwood pulp and add water to prepare a slurry with a mass percent concentration of 4.5%, beat on a ZDC beater, beat for 1.5 hours with a light knife, 2.5 hours with a medium knife, and 1 hour with a heavy knife, for a total of 5 hours. The measured slurry amount is 8.5g, and the degree of beating is 89 ° SR.

[0033] (2) Take 112 g of the wet slurry prepared in step (1) and add it to a 1500 mL three-neck bottle equipped with a constant pressure dropping funnel and a mechanical agitator, dilute with water until the fiber mass percentage is 0.5%, and fully stir for 1 h. Then add 5.10g of calcium nitrate tetrahydrate, stir to dissolve and continue to stir for 1h, then add solid NaOH to adjust the pH to 9.50; then slowly add 4.54g of ethyl orthosilicate with a mass fraction of 99.0%, and continue the reaction at room temperature for 3h after dripping , left to age for 12 hours; filtered, washed 3 times with distilled water, placed in a vacuum oven at 50°...

Embodiment 3

[0039] (1) Take 150kg of coniferous wood pulp and add water to make a slurry with a mass percentage concentration of 4.75%, beat on a ZDC type beater, beat with a light knife for 1.0h, beat with a medium knife for 2.5h, and knock with a heavy knife for 1.5h, a total of 5.0h . The measured pulping amount is 8.8g, and the degree of beating is 90°SR.

[0040] (2) Take 105.3 g of the wet slurry beaten in step (1) and add it to a 1500 mL three-necked bottle equipped with a constant pressure dropping funnel and mechanical agitation, dilute with water until the fiber mass percentage is 0.45%, and fully stir for 1.5 h, then add 7.60g of calcium nitrate tetrahydrate, stir to dissolve and continue to stir for 1.5h, then add solid NaOH to adjust the pH to 10.10; Continue to react for 3.5 hours, stand and age for 18 hours; filter, wash 4 times with distilled water, and dry in a vacuum drying oven at 70°C until constant weight to obtain a cellulose-loaded porous calcium silicate filter ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com