Pipeline mixed oil monitoring system based on terahertz frustrated total internal reflection

A technology of suppressed total internal reflection and monitoring system, applied in measurement devices, material analysis by optical means, instruments, etc., can solve the problems of low detection accuracy, low measurement accuracy, low detection resolution, etc. The effect of strong penetrating ability, simple detection structure and safe detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

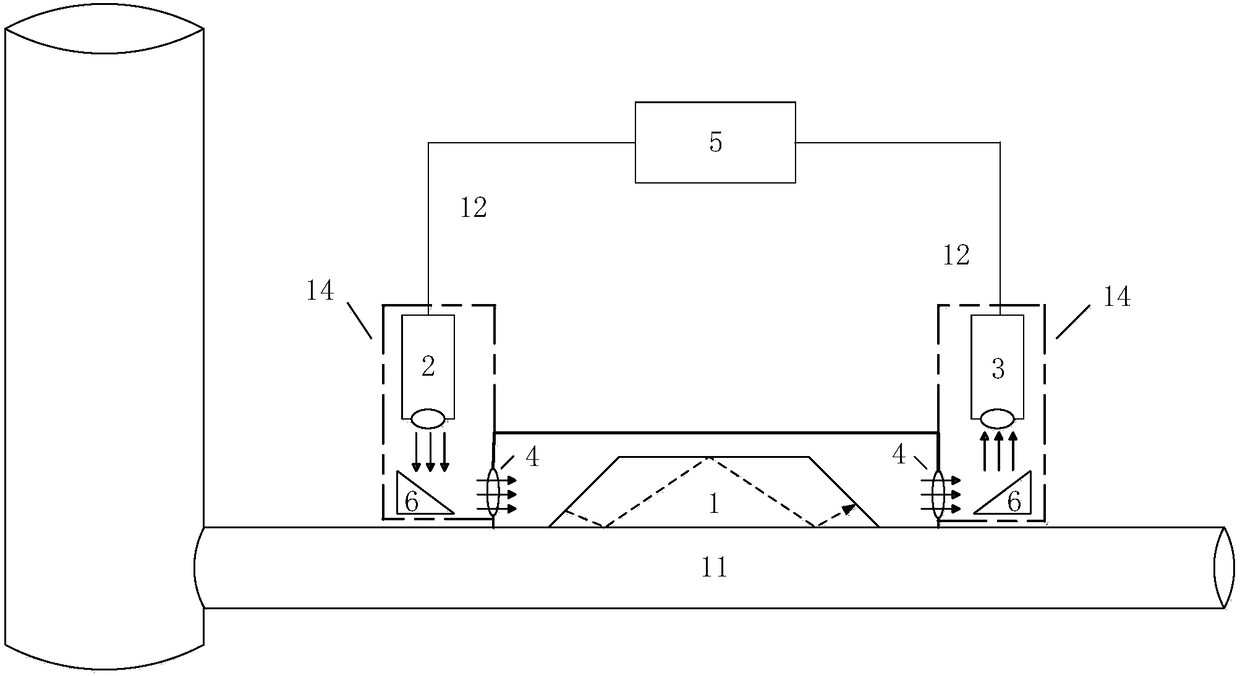

[0040] A pipeline oil-contaminated monitoring system based on terahertz frustrated total internal reflection, see figure 1 , the system includes: a terahertz frustrated total internal reflection prism sensor 1, a transmitter 2, a receiver 3, a terahertz window 4, and a terahertz instrument 5,

[0041] The terahertz instrument 5 continuously outputs terahertz waves, and is always in a fast real-time scanning state, and its sampling frequency is much higher than that of traditional pipeline mixed oil detection;

[0042] The terahertz wave emitted by the transmitter 2 passes through the terahertz window 4 and hits the left incident surface of the terahertz frustrated total internal reflection prism sensor 1, where refraction and reflection occur, and the refracted part enters the interior of the sensor 1; the terahertz wave During the propagation process inside the sensor 1, the frustrated total internal reflection phenomenon occurs on the surface of the sensor 1 in contact with ...

Embodiment 2

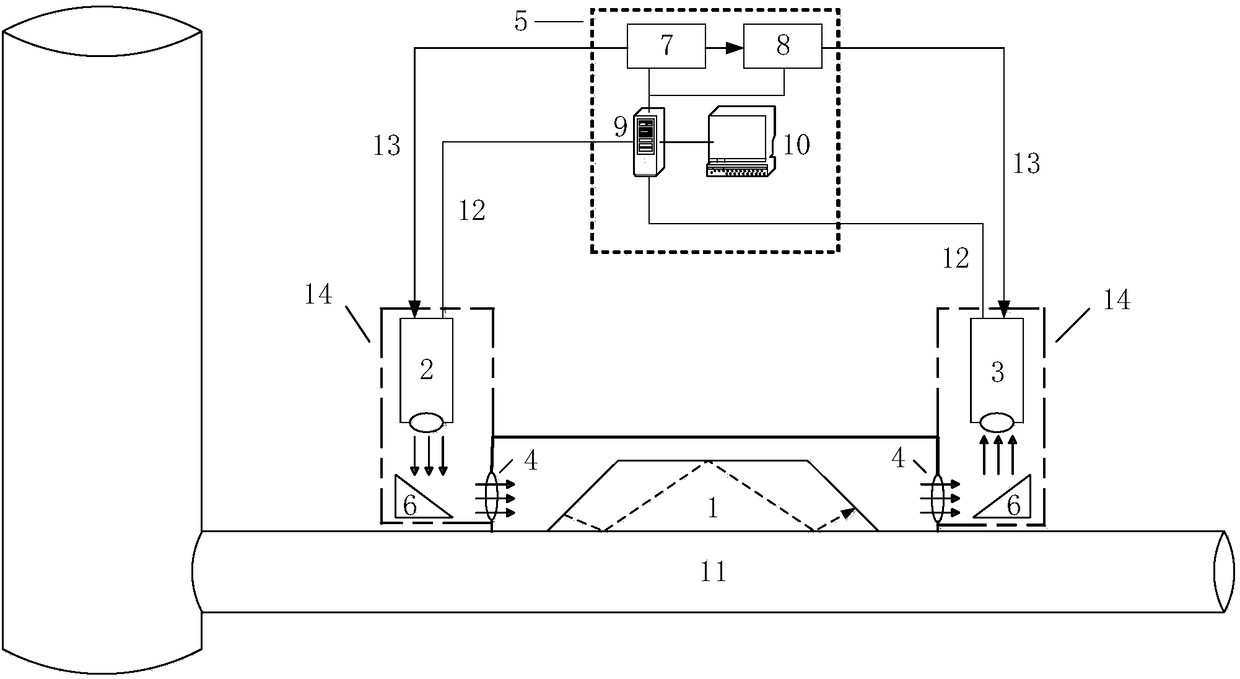

[0054] The difference between the embodiment of the present invention and embodiment 1 is that the terahertz instrument 5 is replaced by a specific device, which is combined below figure 2 For a further introduction to the terahertz instrument 5 in Embodiment 1, see the following description for details:

[0055] In specific implementation, the terahertz instrument 5 may be a terahertz time-domain spectrometer, and correspondingly, the transmitter 2 and the receiver 3 are respectively: a terahertz transmitter and a terahertz receiver.

[0056] see figure 2 , the model of terahertz time-domain spectrometer is MenloSystems TERA K15, including: laser 7, optical delay line (Optical Delay) 8, lock-in amplifier and controller 9, computer 10.

[0057] The laser 7 has a repetition rate of 100MHz and a wavelength of 1560nm. It adopts dual optical fiber coupling output, and is connected to a terahertz transmitter and a terahertz receiver using a polarization-maintaining fiber. The to...

Embodiment 3

[0066] The difference between the embodiment of the present invention and the embodiment 1 is that the terahertz instrument 5 is replaced by a specific device. The terahertz instrument 5 in the embodiment 1 will be further introduced below, see the following description for details:

[0067] In specific implementation, the terahertz instrument 5 is a single-frequency terahertz instrument, and correspondingly, the transmitter 2 and the receiver 3 are respectively: a single-frequency terahertz source and a terahertz detector.

[0068] When the terahertz instrument 5 is a single-frequency terahertz instrument, extracting the information of the terahertz wave spectrum specifically includes: extracting intensity information.

[0069] In summary, the system designed in the embodiment of the present invention, compared with other detection methods for pipeline oil contamination, the system not only has high detection accuracy, low photon energy, safe detection process, strong terahert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Repetition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com