High temperature-resistant composite cement-based material and preparation method thereof

A technology of composite cement and base materials, applied in the field of cementitious materials, can solve the problems of cement-based materials such as reduced strength and poor fire resistance, and achieve the effects of increased strength, long setting time, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh the preparations by the following parts by weight:

[0034] The specific surface area is 500m 2 / kg, alkalinity coefficient is 1.1, activity coefficient is 60 parts of slag (the slag with smaller specific surface area can be ground by ball mill);

[0035] The specific surface area is 550m 2 30 parts of metakaolin per kg;

[0036] 10 parts of calcined bauxite whose grade is first-class special grade;

[0037] The specific surface area is 600m 2 5 parts / kg of aluminum hydroxide powder;

[0038] 5 parts of sodium hydroxide;

[0039] 0.00015 copies of 4mm composite ecological fiber;

[0040] 6mm steel fiber 0.002 parts;

[0041] Solid content 45%, modulus is 30 parts of commercially available water glass of 3.3;

[0042] 0.1 parts of YP-3 retarder;

[0043] 26 parts of water.

[0044] Process as follows:

[0045] 1), slowly dissolve 5 parts of the weighed sodium hydroxide in 26 parts of the weighed water, prepare the sodium hydroxide solution, and place it ...

Embodiment 2

[0053] For comparison, ordinary Portland cement specimens were mixed and formed under laboratory conditions:

[0054] Prepare by weight:

[0055] Ordinary 52.5R Portland cement 100 parts;

[0056] 40 parts of water.

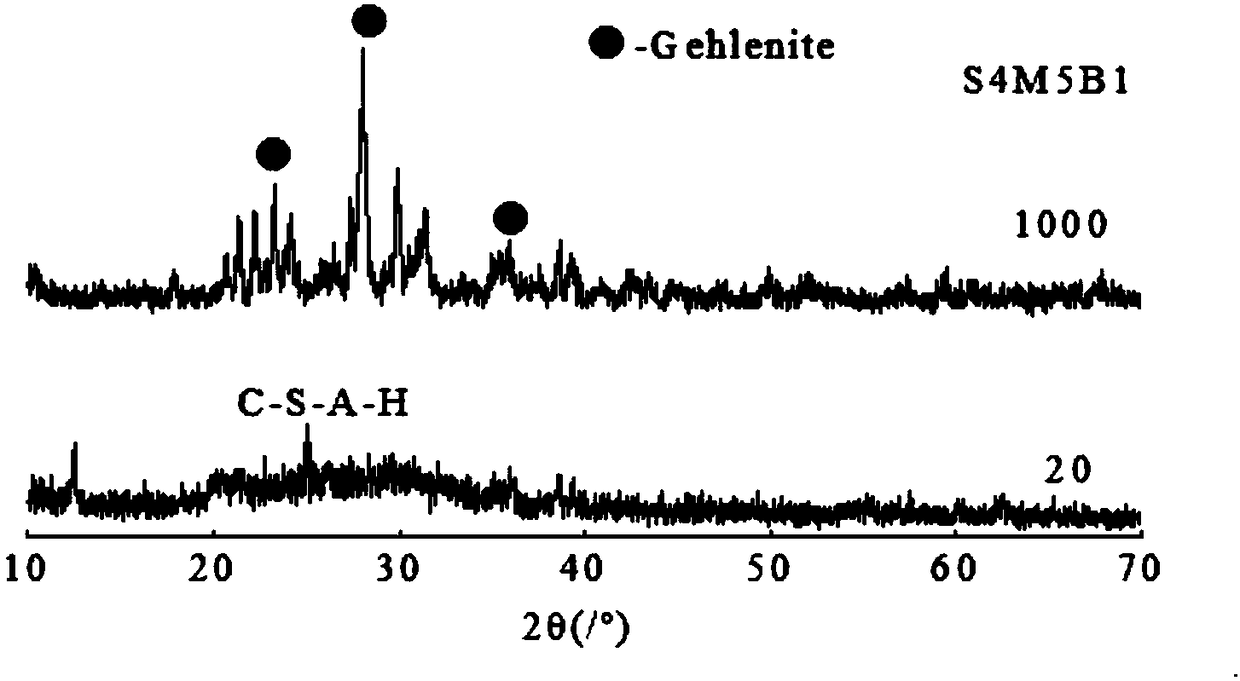

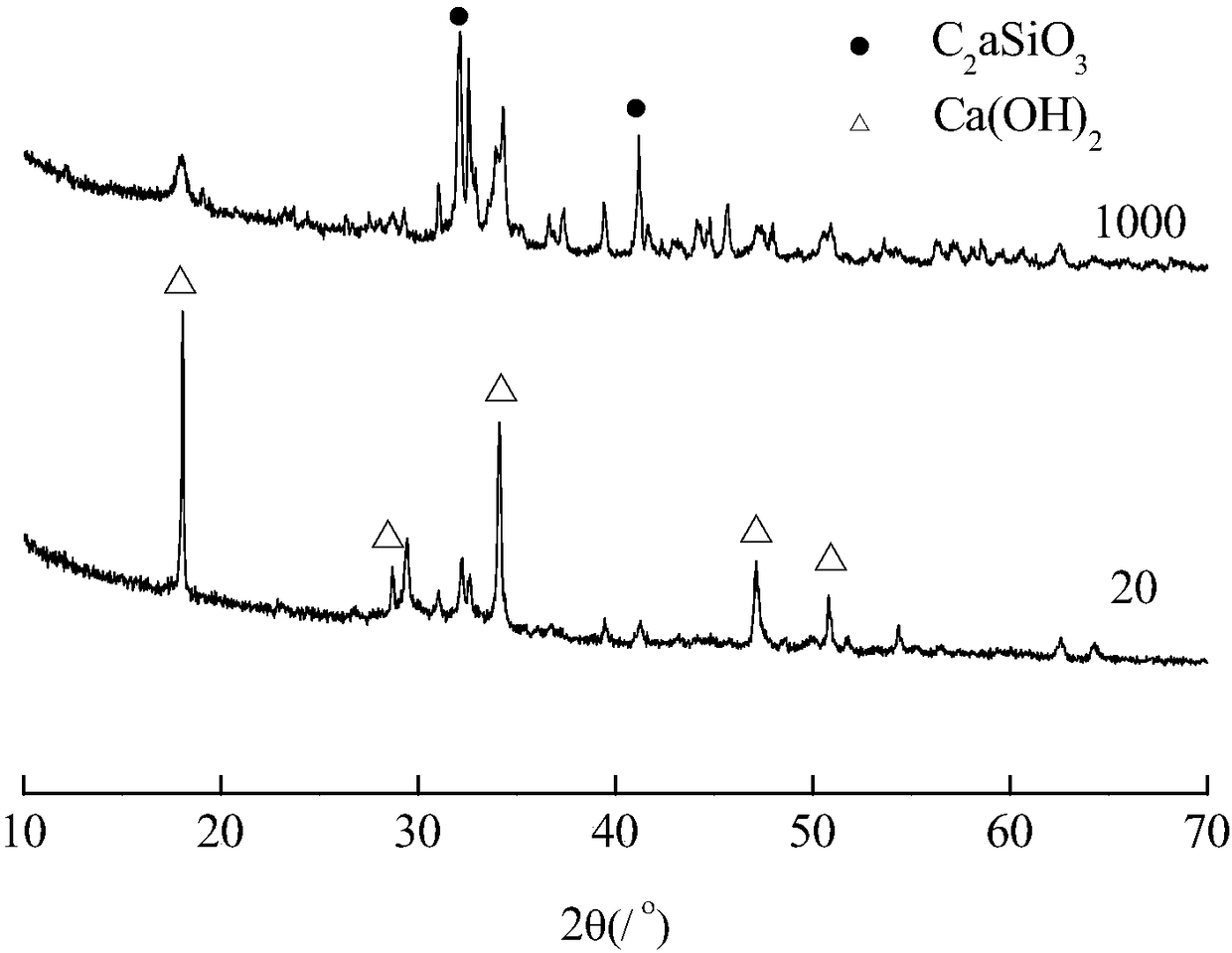

[0057] A cube specimen of 40mm×40mm×40mm was prepared from the obtained slurry according to the proportion, and the compressive strength at 28 days of age was 62.5MPa. After 2 hours of high temperature exposure at 1000 ° C, the specimen was destroyed, and the residual strength was 0. See the macroscopic photo and microscopic composition of the specimen. image 3 and Figure 4 .

Embodiment 3

[0059] This implementation case is an embodiment of molding different proportions under laboratory conditions.

[0060] Prepare materials according to the weight in Table 1:

[0061] Table 1 raw material ratio (by mass)

[0062]

[0063]

[0064] In Table 1, the physical properties of the relevant raw materials are shown in Table 2:

[0065] The physical property parameter of raw material in table 2 table 1

[0066]

[0067] The number A in Table 2 represents the material parameters used in the mix ratio of A1-A6 group in Table 1, and correspondingly, B represents the mix ratio of B1-B6 group, and C and D follow this rule.

[0068] Process as follows:

[0069] 1), slowly dissolve the weighed sodium hydroxide in the weighed water, prepare the sodium hydroxide solution, and place it to room temperature;

[0070] 2), take commercially available water glass by weight, the sodium hydroxide solution that will be placed to room temperature is mixed with commercially avai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com