A kind of low dielectric loss fluorosilicone compound rubber and preparation method thereof

A technology of mixing rubber and low medium is applied in the field of fluorosilicone rubber compound with low dielectric loss and its preparation, which can solve the problem of serious dielectric loss of fluorosilicone rubber, and achieve the effects of excellent oil resistance and excellent low temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

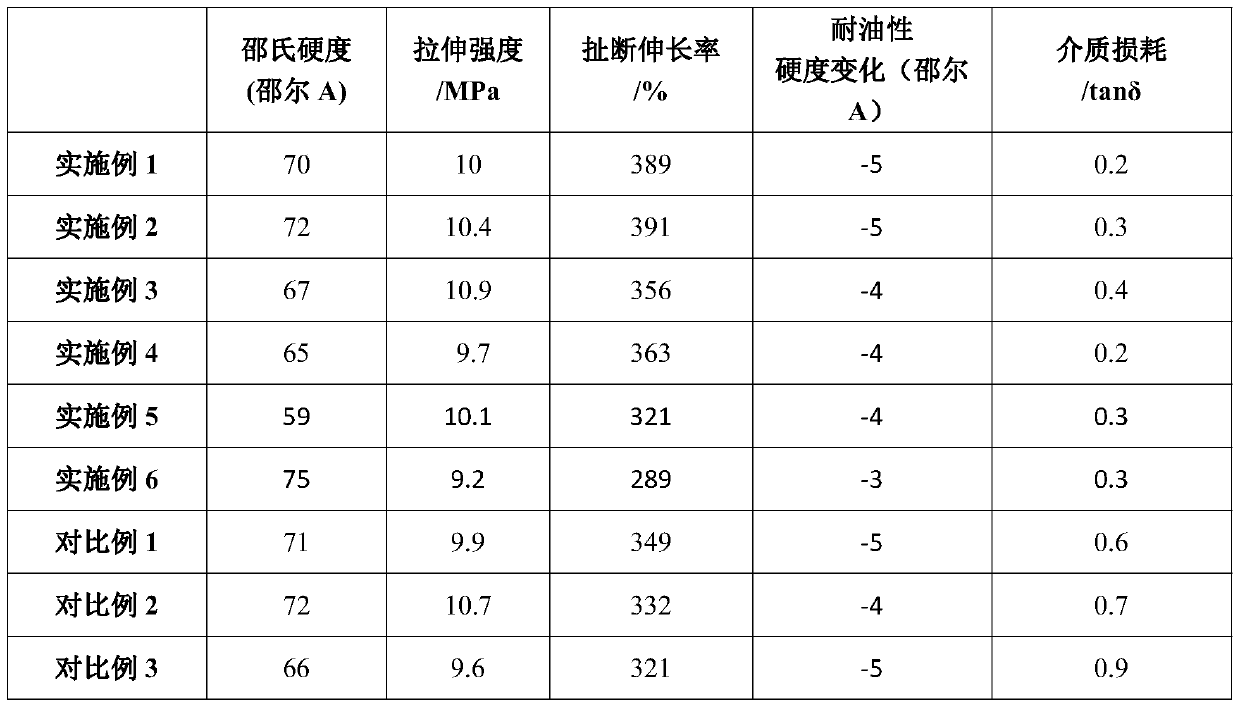

Examples

Embodiment 1

[0030] Take 100 parts of oligomer / ring body content 0.3% fluorosilicone raw rubber, add 12 parts of ring body content 4% hydroxyl fluorosilicone oil in batches to the open mill, 50 parts of specific surface area 250m 2 / g of fumed white carbon black, after mixing evenly, carry out vacuuming and heat treatment at 150°C×2h, the temperature drops to 50°C, add 1 part of cerium oxide, and add 0.8 parts of 2,5-dimethyl- 2,5-bis (tert-butylperoxy) hexane (hereinafter referred to as: double two five), thin pass, the next piece, the conditions are 170 ℃ × 15min one-stage vulcanization and 200 ℃ × 4h two-stage vulcanization preparation Test piece, to test the basic performance, oil resistance and dielectric loss.

Embodiment 2

[0032] Take 100 parts of oligomer / ring body content of 0.3% fluorosilicone raw rubber, add 12 parts of ring body content of 1% hydroxyl fluorosilicone oil in batches to the open mill, 50 parts of specific surface area 250m 2 / g of fumed white carbon black, after mixing evenly, carry out vacuuming and heat treatment at 150°C×2h, the temperature is lowered to 50°C, add 3 parts of iron oxide, add 0.8 parts of Shuangerwu to the open mill, Botong, Xiatong The test pieces were prepared by performing one-stage vulcanization at 170°C for 15 minutes and two-stage vulcanization at 200°C for 4 hours to test basic performance, oil resistance and dielectric loss.

Embodiment 3

[0034] Take 100 parts of oligomer / ring body content of 0.4% fluorosilicone raw rubber, add 10 parts of ring body content of 1% hydroxyl fluorosilicone oil in batches to the open mill, 47 parts of specific surface area 200m 2 / g of fumed white carbon black, after mixing evenly, carry out vacuuming and heat treatment at 150°C×2h, the temperature is lowered to 50°C, add 3 parts of iron oxide, add 0.8 parts of Shuangerwu to the open mill, Botong, Xiatong The test pieces were prepared by performing one-stage vulcanization at 170°C for 15 minutes and two-stage vulcanization at 200°C for 4 hours to test basic performance, oil resistance and dielectric loss.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com