Alloy saw blade with different materials

A saw blade and alloy technology, which is applied in the field of alloy saw blades, can solve the problems of inconvenient machining, insufficient hardenability, poor plate shape, etc., and achieve the effects of convenient cutting, convenient thinning treatment, and increased hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

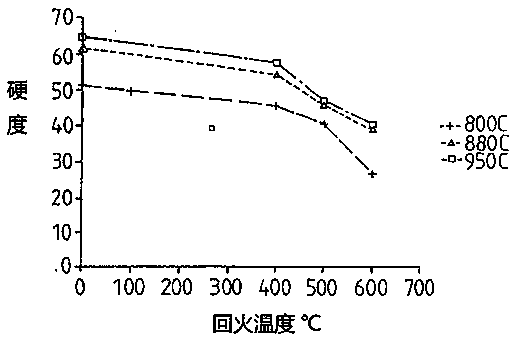

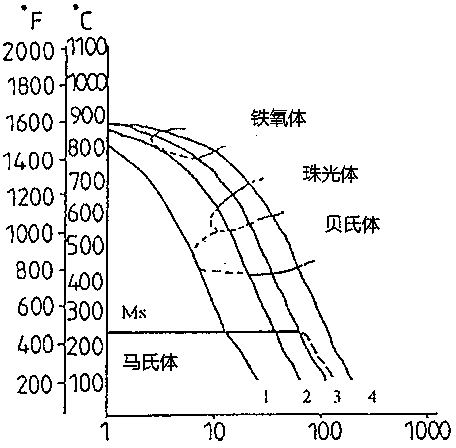

[0021] The application discloses an alloy saw blade with different materials, which includes a steel alloy saw blade, the components of the steel alloy saw blade and the weight ratio of each component are: 0.55~0.9 carbon; 1~2 silicon; maximum 0.2 manganese; 0.1-0.5% chromium; and a trace element selected from the group consisting of niobium, tantalum, vanadium, titanium, zirconium, aluminum, sulfur, phosphorus and nitrogen in a content of up to 0.2%; and iron in the balance ;Steel alloy saw blades have tempered martensite and remaining carbides, and steel alloy saw blades have been hardened at temperatures between 780°C and 1000°C, and tempered at temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com