Lithium ion battery composite negative electrode material and preparation method thereof

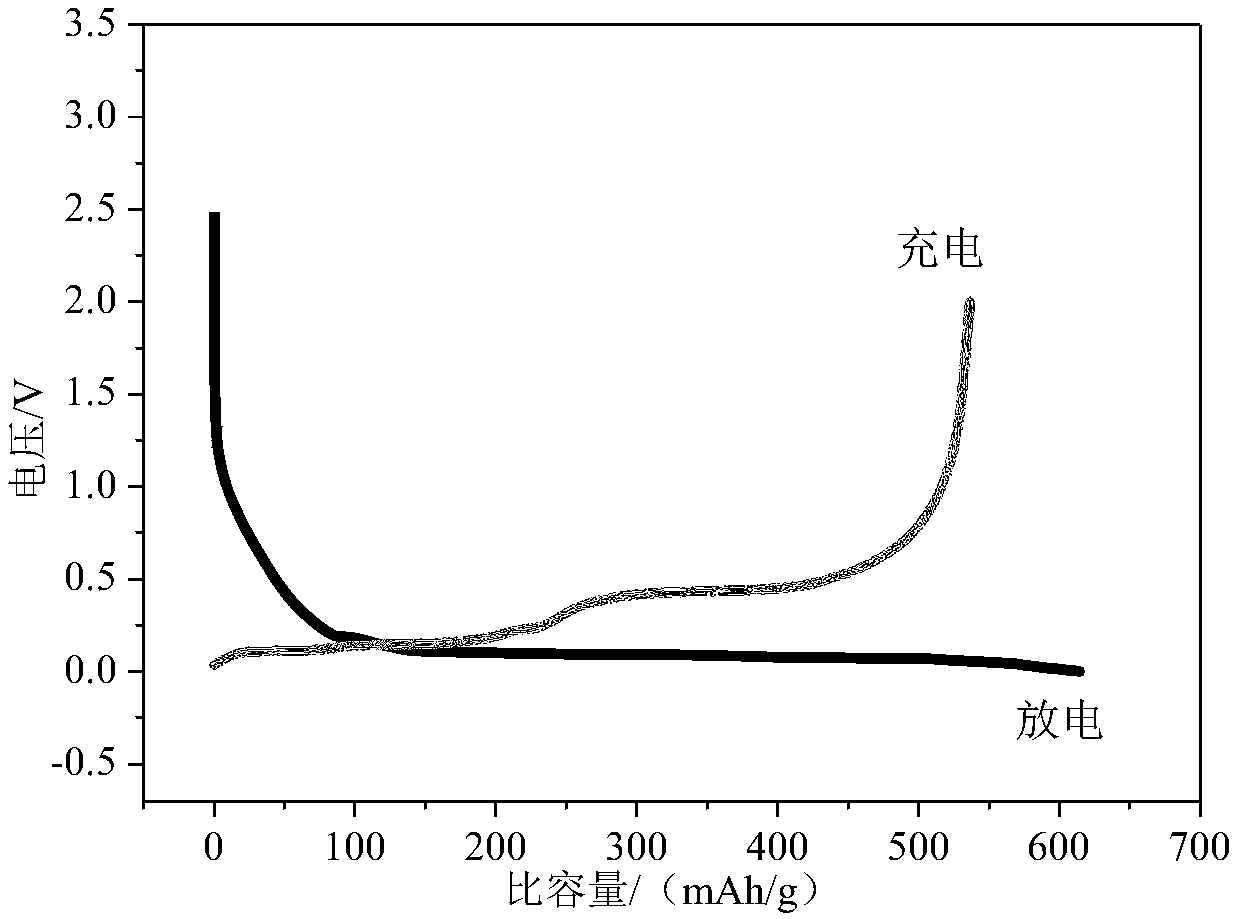

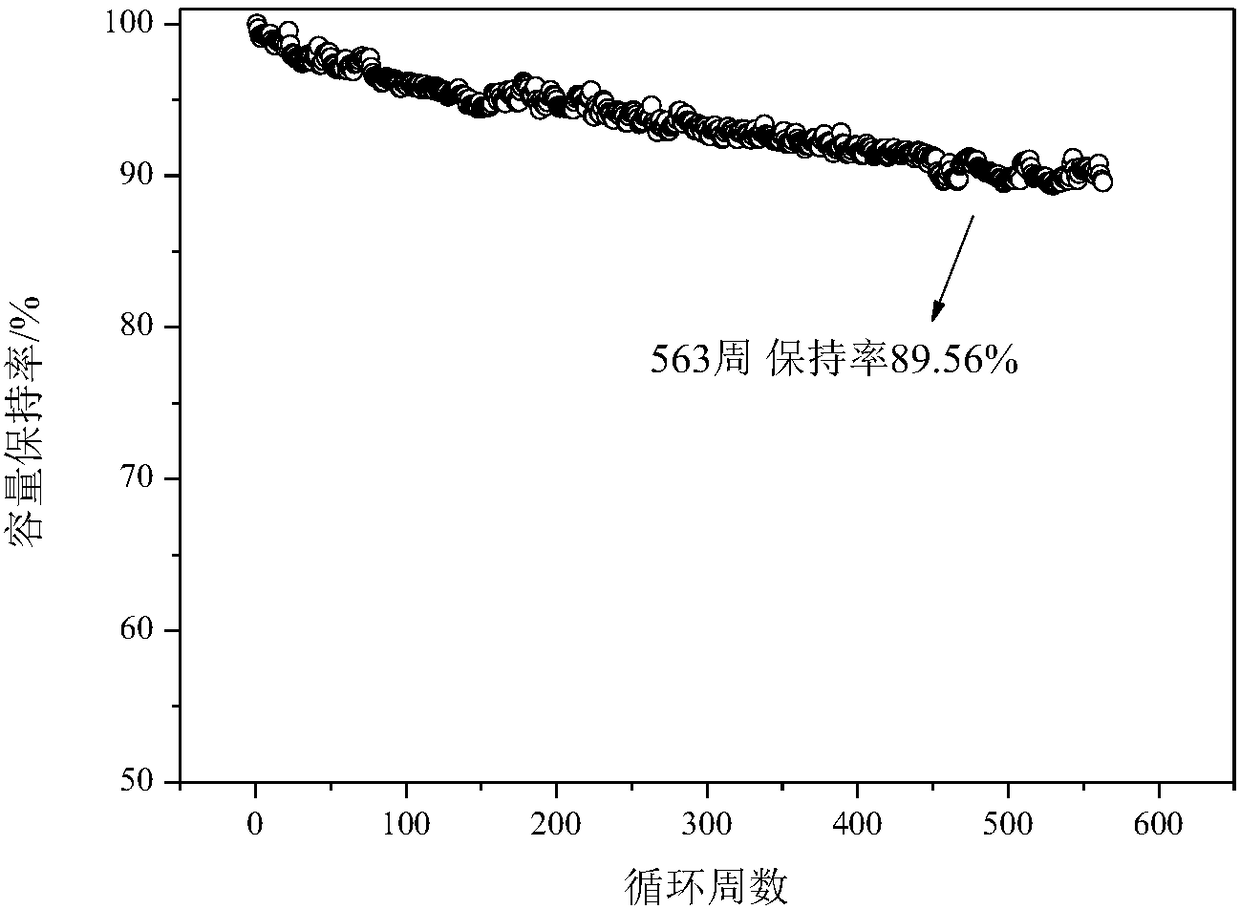

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low specific capacity of graphite, loss of electrical contact, and poor connectivity, so as to alleviate volume expansion and save energy. , the effect of excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The present invention also provides a preparation method of a lithium-ion battery composite negative electrode material, comprising the steps of:

[0022] Step 1: Disperse graphene in distilled water, then add graphite, after stirring, add silicon-based material, stir to form a mixed material; the mass ratio of the silicon-based material to the graphite is 1: (1-10) , the mass ratio of the graphite to the graphene is 100:(0.01~5);

[0023] Step 2: Take the mixed solution of aniline monomer and HCl solution and add it to the mixed material prepared in Step 1, and then add the mixed solution of ammonium persulfate and HCl solution after stirring, and react for a period of time to obtain the polymer compound containing the first coating layer. primary mixture of aniline;

[0024] Step 3: Add the mixed solution of pyrrole monomer and HCl solution to the primary mixed solution prepared in Step 2, and then add the mixed solution of ammonium persulfate and HCl solution after ...

Embodiment 1

[0028] (1) Get 0.05g graphene and disperse in distilled water through 15h mechanical stirring and 20h ultrasonic stirring, then add 50g graphite, after carrying out 4h mechanical stirring, add 8g particle diameter and be the silicon-based material of 10~200nm, through 2h mechanical stirring, form a mixed material;

[0029] (2) Add 8 g of aniline monomer and 100 g of HCl solution with a concentration of 2 mol / L to the mixed material prepared in (1), mechanically stir for 1 hour, then add 8 g of ammonium persulfate and 100 g of HCl solution with a concentration of 2 mol / L The mixed solution of the HCl solution was reacted for 3 hours to obtain a primary mixed solution containing the polyaniline of the first coating layer;

[0030] (3) Add 8g of pyrrole monomer and 100g concentration of HCl solution of 2mol / L to the primary mixed solution prepared in (2), mechanically stir for 1h and then add 8g ammonium persulfate and 100g concentration of 2mol / L The mixed solution of the HCl s...

Embodiment 2

[0033] (1) Get 0.02g graphene and disperse in distilled water through 10h mechanical stirring and 15h ultrasonic stirring, add 50g graphite again, after carrying out 3h mechanical stirring, add 5g particle diameter and be the silicon-based material of 10~200nm, through 2h mechanical stirring, form a mixed material;

[0034] (2) Add 5 g of aniline monomer and 100 g of HCl solution with a concentration of 2 mol / L to the mixed material prepared in (1), mechanically stir for 2 hours, then add 5 g of ammonium persulfate and 100 g of HCl solution with a concentration of 2 mol / L The mixed solution of the HCl solution was reacted for 2 hours to obtain a primary mixed solution containing the polyaniline of the first coating layer;

[0035] (3) Get 5g of pyrrole monomer and 100g concentration of HCl solution that is 2mol / L and add it into the primary mixed solution prepared in (2), mechanically stir it for 0.5h and then add 5g ammonium persulfate and 100g concentration of 2mol / L The mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com