Anti-allergy face cream

An anti-allergic and face cream technology, which is applied in the field of daily chemicals, can solve the problems of poor anti-allergic effect, achieve anti-allergic effect, strong anti-oxidation and moisturizing properties, and improve blood circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

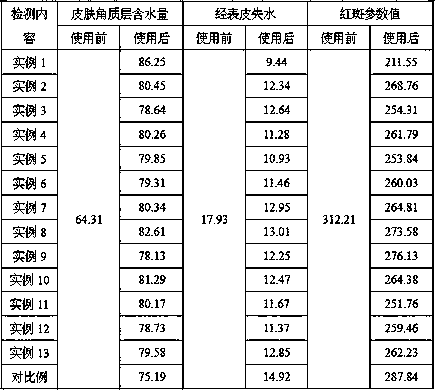

Examples

example 1

[0038]Mix figs and water in a mass ratio of 1:30 and pour them into a grinder, crush them to obtain fig pulp, filter to obtain a filtrate, which is the extract, and mix the obtained extract with Glauber's salt in a mass ratio of 10:3 and pour Put it into a beaker, heat and boil with an alcohol lamp, wait for the material in the beaker to cool naturally to room temperature, move the beaker into the refrigerator, and cool and crystallize for 6 hours at a temperature of 6°C, filter to obtain a filter residue, and put the obtained filter residue at a temperature of 50 Blast drying at ℃ for 6 hours to obtain a dried product, then pour the obtained dried product into a mortar and grind for 5 minutes to obtain a fig extract; mix and grind cactus and water at a mass ratio of 1:8, pass through a 280-mesh square hole sieve to get cactus juice; the sepiolite is poured into the pulverizer, and after pulverizing, it is crossed through a 500 mesh sieve to obtain sepiolite powder, and the gai...

example 2

[0040] Mix and grind cactus and water according to the mass ratio of 1:8, pass through a 280-mesh square hole sieve to obtain cactus juice; pour the sepiolite into a pulverizer, and pass through a 500-mesh sieve after crushing to obtain sepiolite powder, and put The obtained sepiolite powder and hydrochloric acid with a mass fraction of 10% were mixed and poured into a three-necked flask, and the three-necked flask was moved into a digital speed measuring and constant temperature magnetic stirrer, at a temperature of 60°C and a speed of 800r / min, the reaction was stirred at a constant temperature for 4 hours, and filtered , to obtain a filter cake, and the obtained filter cake was washed with deionized water until the washing solution was neutral, then the washed filter cake was transferred to a tube furnace, and roasted for 60 minutes at a temperature of 280 ° C, and cooled with the furnace to room temperature, discharging, to obtain modified sepiolite; in parts by weight, suc...

example 3

[0042] Mix figs and water in a mass ratio of 1:30 and pour them into a grinder, crush them to obtain fig pulp, filter to obtain a filtrate, which is the extract, and mix the obtained extract with Glauber's salt in a mass ratio of 10:3 and pour Put it into a beaker, heat and boil with an alcohol lamp, wait for the material in the beaker to cool naturally to room temperature, move the beaker into the refrigerator, and cool and crystallize for 6 hours at a temperature of 6°C, filter to obtain a filter residue, and put the obtained filter residue at a temperature of 50 Blast-dried at ℃ for 6 hours to obtain a dried product, then pour the obtained dried product into a mortar and grind for 5 minutes to obtain fig extract; foam stone powder, and mix the obtained sepiolite powder and 10% hydrochloric acid into a three-necked flask, and move the three-necked flask into a digital speed measuring constant temperature magnetic stirrer, at a temperature of 60°C and a speed of 800r / min. Sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com