Catalyst for synthesis of dimethyl carbonate by using gas-phase method and preparation and application of catalyst

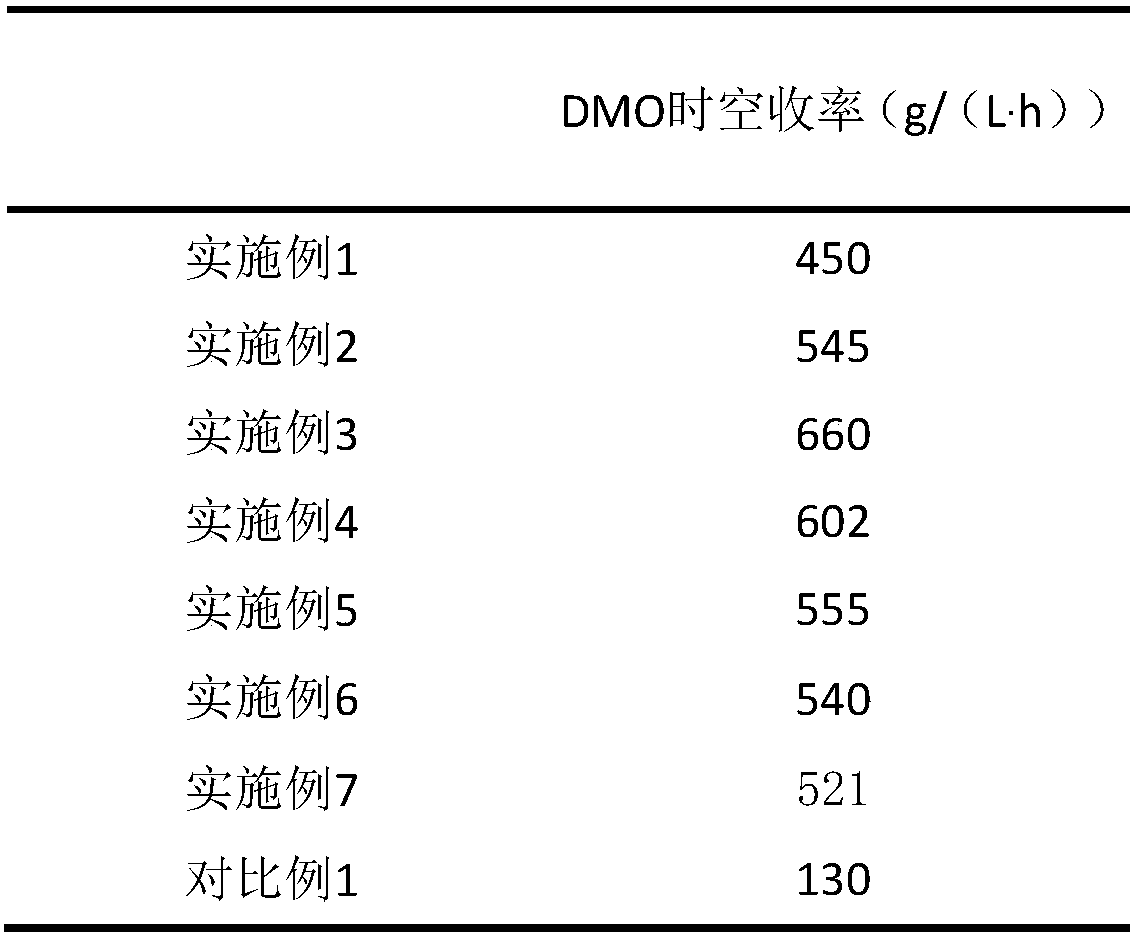

A technology of dimethyl carbonate and catalysts, which is applied in the field of embedded nano-Pd particle catalysts and its preparation, can solve the problems of catalyst activity and service life, chlorine-containing catalysts corrode equipment, etc., and achieve the elimination of equipment corrosion problems and good stability , the effect of high space-time yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 0.1g sucrose to 10ml deionized water to prepare a solution, and 10g α-Al 2 o 3 The carrier was impregnated in sucrose solution, dried naturally, then placed in an electric blast drying oven, dried at 100°C for 12 hours, and finally dried in N 2 Carbonization at 800°C for 4 hours under atmosphere to obtain a carbonized composite carrier. Dissolve 0.2510g of potassium acetate and 0.3771g of copper acetate in 10ml of deionized water to prepare a mixed solution of auxiliary active component salt. Then 10g of carbonized composite carrier was added into the mixed solution of co-active components, immersed for 8h, dried naturally, dried in a blast oven at 80°C for 12h and baked in a muffle furnace at 400°C for 2h. Add 0.2110g of palladium acetate to 16ml of acetone, and then sonicate in an ultrasonic instrument at 30°C and 20KHz for 30min to prepare a 0.006g Pd / ml solution. Then add the carbonized composite carrier loaded with additives into the main active component so...

Embodiment 2

[0027] Add 0.2g sucrose to 10ml deionized water to prepare a solution, and 10g α-Al 2 o 3 The carrier was impregnated in sucrose solution, dried naturally, then placed in an electric blast drying oven, dried at 100°C for 12 hours, and finally dried in N 2 Carbonization at 800°C for 4 hours under atmosphere to obtain a carbonized composite carrier. Dissolve 0.2510g of potassium acetate and 0.3771g of copper acetate in 10ml of deionized water to prepare a mixed solution of auxiliary active component salt. Then 10g of carbonized composite carrier was added into the mixed solution of co-active components, immersed for 8h, dried naturally, dried in a blast oven at 80°C for 12h and baked in a muffle furnace at 400°C for 2h. Add 0.2110g of palladium acetate to 16ml of acetone, and then sonicate in an ultrasonic instrument at 30°C and 20KHz for 30min to prepare a 0.006g Pd / ml solution. Then add the carbonized composite carrier loaded with additives into the main active component so...

Embodiment 3

[0029] Add 0.4g sucrose to 10ml deionized water to prepare a solution, and 10g α-Al 2 o 3 The carrier was impregnated in sucrose solution, dried naturally, then placed in an electric blast drying oven, dried at 100°C for 12 hours, and finally dried in N 2 Carbonization at 800°C for 4 hours under atmosphere to obtain a carbonized composite carrier. Dissolve 0.2510g of potassium acetate and 0.3771g of copper acetate in 10ml of deionized water to prepare a mixed solution of auxiliary active component salt. Then 10g of carbonized composite carrier was added into the mixed solution of co-active components, immersed for 8h, dried naturally, dried in a blast oven at 80°C for 12h and baked in a muffle furnace at 400°C for 2h. Add 0.2110g of palladium acetate to 16ml of acetone, and then sonicate in an ultrasonic instrument at 30°C and 20KHz for 30min to prepare a 0.006g Pd / ml solution. Then add the carbonized composite carrier loaded with additives into the main active component so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com