Fenton catalytic material as well as preparation method and application thereof

A catalytic material, Fenton's technology, is used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. It can solve the problems of slow catalytic reaction rate and low activity, and achieve lower preparation costs and high catalytic activity. , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of material FeCeOx belongs to coprecipitation method, comprises the following steps:

[0035] 1) Precursor preparation: Disperse soluble ferrous salt and cerium salt in 100ml of water at a molar ratio of 1:2, with a total metal ion concentration of 0.1mol / l, and stir evenly in a constant temperature water bath at 40°C; add an appropriate amount of Concentrated ammonia water, adjust the pH of the system to 9.3-9.5, continue to stir for 2 hours; keep the temperature unchanged, let it stand for 12 hours; then carry out solid-liquid separation, wash the obtained solid precipitate with deionized water 3 times, and place it in an oven at 105°C Dry for 10 hours to obtain the precursor.

[0036] (2) Calcination: The obtained precursor was placed in a muffle furnace, calcined at 500°C for 3 hours in an air atmosphere, and cooled naturally to obtain FeCeOx, an iron-doped ceria-like Fenton-like catalytic material.

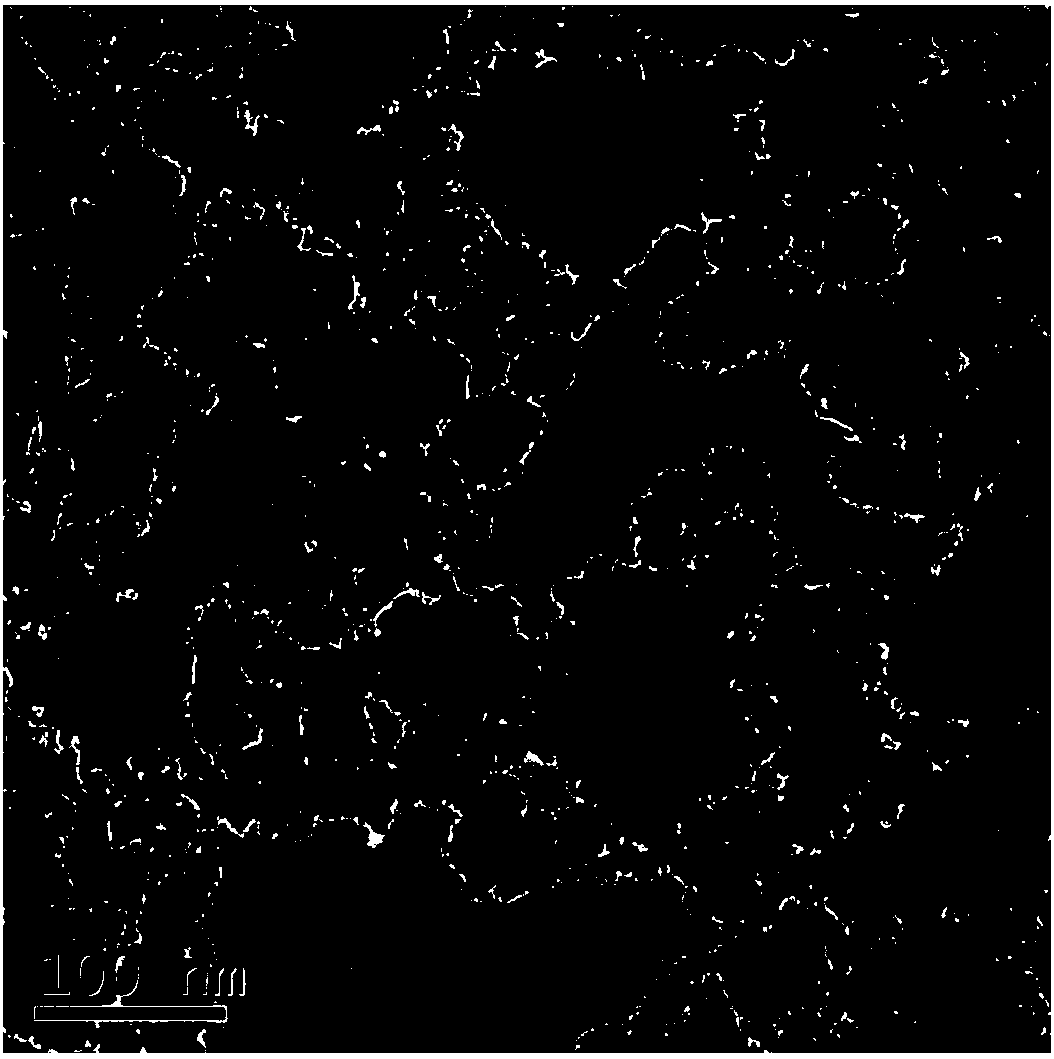

[0037] figure 1 and figure 2 It is the...

Embodiment 2

[0039] The preparation method of material FeCeOx belongs to coprecipitation method, comprises the following steps:

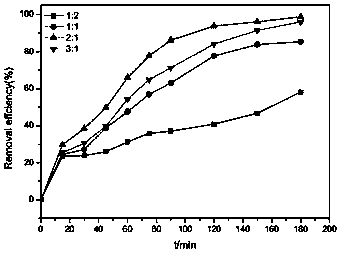

[0040] 1) Precursor preparation: respectively disperse soluble ferrous salt and cerium salt in 100ml of water at a molar ratio of 1:0.5, 1:1, 1:2 and 1:3, the total metal ion concentration is 0.1mol / l, Stir evenly in a constant temperature water bath at 40°C; add an appropriate amount of concentrated ammonia water, adjust the pH of the system to 9.3-9.5, and continue stirring for 2 hours; keep the temperature unchanged, and leave it to age for 12 hours; then carry out solid-liquid separation and precipitate the obtained solid Wash 3 times with deionized water, dry in an oven at 105°C for 10 hours, and obtain the precursor.

[0041] (2) Calcination: The obtained precursors were placed in a muffle furnace and calcined at 500 °C for 3 h in an air atmosphere. After natural cooling, four different iron-doped ceria-like Fenton catalytic materials FeCeOx were obtained....

Embodiment 3

[0043] The impact of material FeCeO dosage on the removal of organic dye Rhodamine B (RhB) comprises the following steps:

[0044] 1) according to the material preparation method described in embodiment 1, prepare material FeCeOx;

[0045] 2) FeCeOx materials of different qualities were weighed and put into conical flasks equipped with 100ml 100mg / l RhB solution (pH=5.0), and the dosages of FeCeOx materials were respectively controlled to be 0.5g / L, 1.0g / L, 1.5 g / L and 2.0g / L, add 80mM hydrogen peroxide respectively.

[0046] 3) React the mixed solution in a shaker at a temperature of 35±1° C. at a speed of 250 r / min. Samples were taken at set time points for analysis.

[0047] Figure 4 It is the relationship diagram of the effect of the dosage of material FeCeOx on the removal of organic dye Rhodamine B (RhB). Figure 4It can be seen that the catalyst dosage increases from 0.5g / L to 1.5g / L, and the 2h dye degradation rate increases from about 40% to 90%, while the differ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com