A kind of nickel-based alloy weld microstructure and grain refinement method and its application

A technology of nickel-based alloy and grain refinement, which is applied in welding equipment, welding medium, welding equipment, etc., can solve the problems that the refiner cannot be evenly distributed and the crystal grains are coarse, so as to solve the problem of coarse weld structure and improve Strong toughness, effect of promoting nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In the method for refining the structure of nickel-based alloy welds in this embodiment, the nickel-based alloy used is nickel 718 alloy, and its chemical composition mass percentage is: C: 0.05%, Mn: 0.1%, Fe: 20%, P: 0.01% , S: 0.001%, Si: 0.06%, Al: 0.45%, Ti: 1.0%, Cr: 17.4%, Nb: 5%, Mo: 3.0%, Ni: balance.

[0034] The raw materials of the nickel-based alloy are: high-carbon ferromanganese powder, high-carbon ferrochrome powder, ferromolybdenum powder, pure iron powder, high-purity metal niobium powder, high-purity metal aluminum powder, high-purity metal titanium powder, high-purity metal nickel powder and high-purity silica fume. These powders are all commercially available.

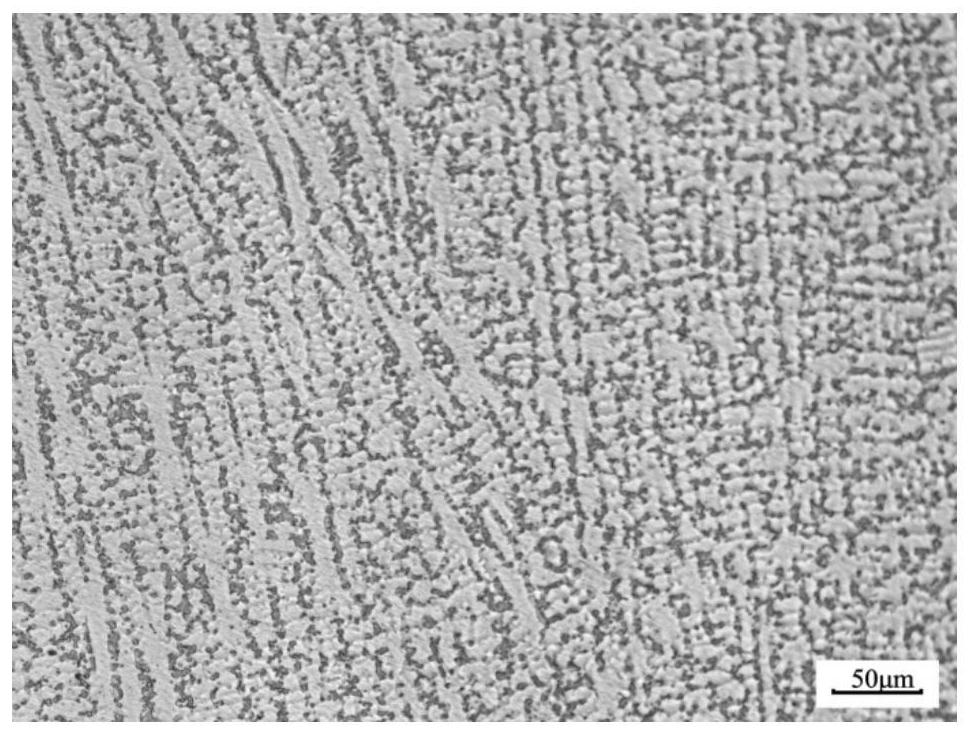

[0035]Prepare nickel 718 alloy powder according to the above-mentioned nickel-based alloy formula; Then add mass fraction in the above-mentioned nickel 718 alloy powder and be 0.2% (0.2% here is 0.2% of the quality of nickel 718 alloy powder raw material, the same below) diameter is 100nm ...

Embodiment 2-5

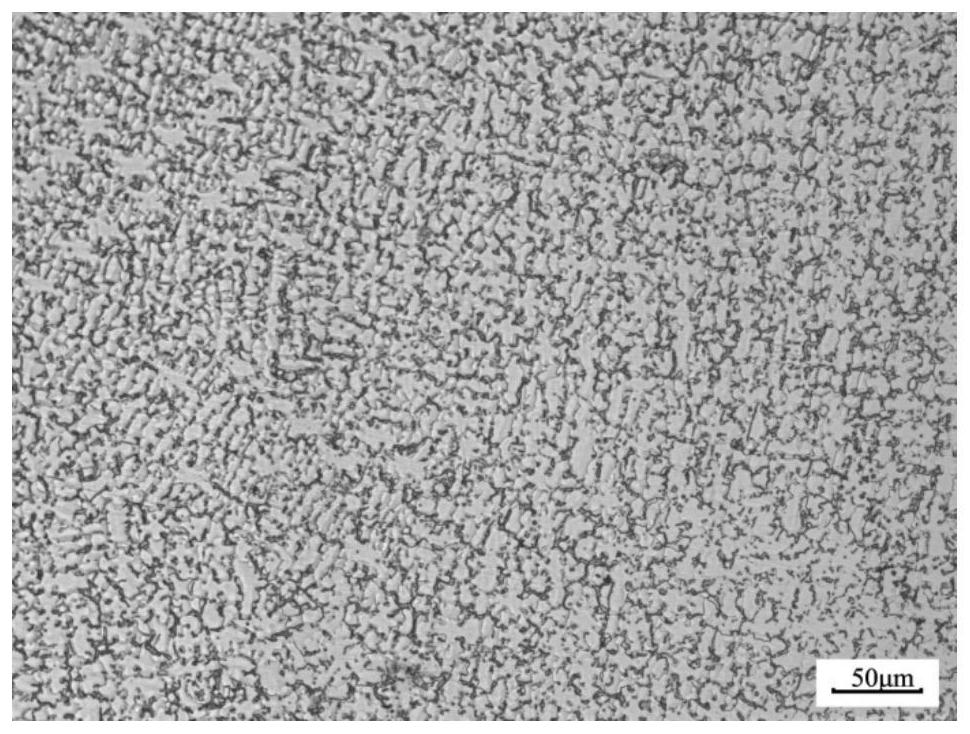

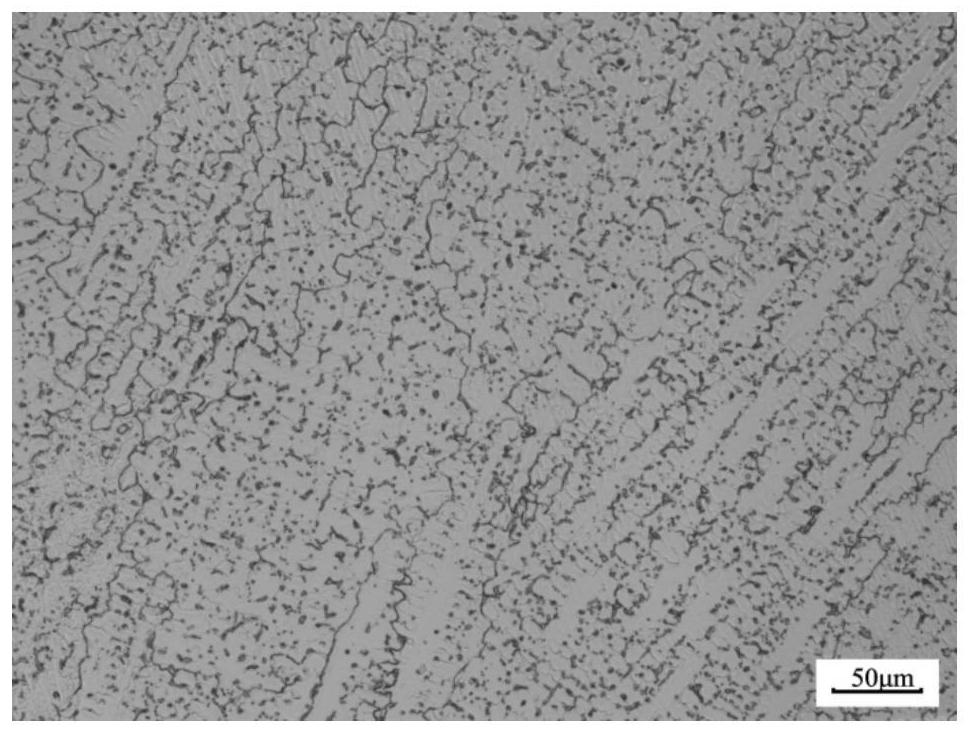

[0042] In the refinement method of embodiment 2-5, each step is the same as embodiment 1, and the welding process is also the same as embodiment 1, and the difference is that the content of adding nano-titanium dioxide refiner is different. After refinement in each embodiment, the nickel base alloy See Table 2 for the mass percent of each component.

[0043] And according to the micro-Vickers hardness tester with reference to the GBT4340.1-2009 national standard, the microhardness of the samples in each embodiment was measured.

[0044] Ingredient mass percent (wt %) in each embodiment of table 2

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com