Siliceous sponge bone spicule purifying method, purifying system and application

A purification method and sponge technology, applied in the direction of silicon oxide, silicon dioxide, etc., can solve the problems such as the difficulty of 100% purification of sponge bone spicules, the complicated and dangerous process, and the failure to remove negative charges, and achieve improved safety, high purity, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

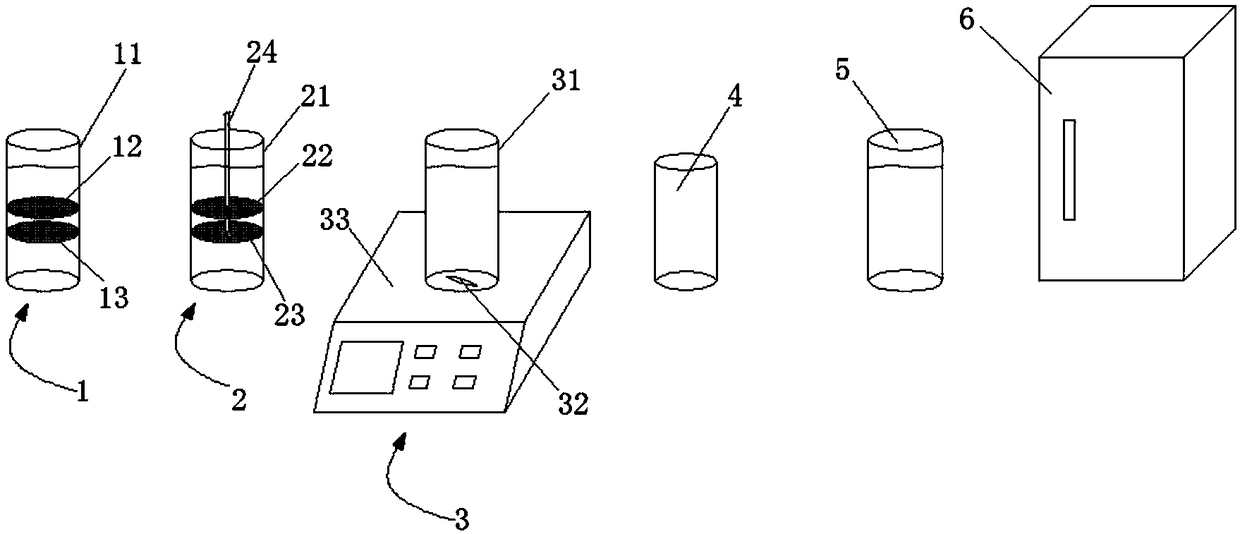

[0042] as attached figure 2 As shown, the present embodiment provides a purification system for siliceous spicules, including a specific gravity filter device 1 for containing the overweight filtrate to soak the siliceous spicules to remove impurities, and for containing the dispersion liquid to remove impurities. Dispersion filtering device 2 for further removing impurities from the siliceous spongy bone needles that have been removed by the specific gravity filter device 1, used to contain polar cleaning liquid to remove impurities from the siliceous spongy bone needles that have been removed by the dispersive filtering device 2 A polarity removal device 3 for washing and depolarizing the needles, a vibrating sieving machine 4 for sieving the siliceous sponge spicules depolarized by the polarity removal device 3 to obtain siliceous spongy spicules of uniform size , a cleaning device 5 for containing distilled water to clean the siliceous spongy spicules sorted by the vibrat...

Embodiment 2

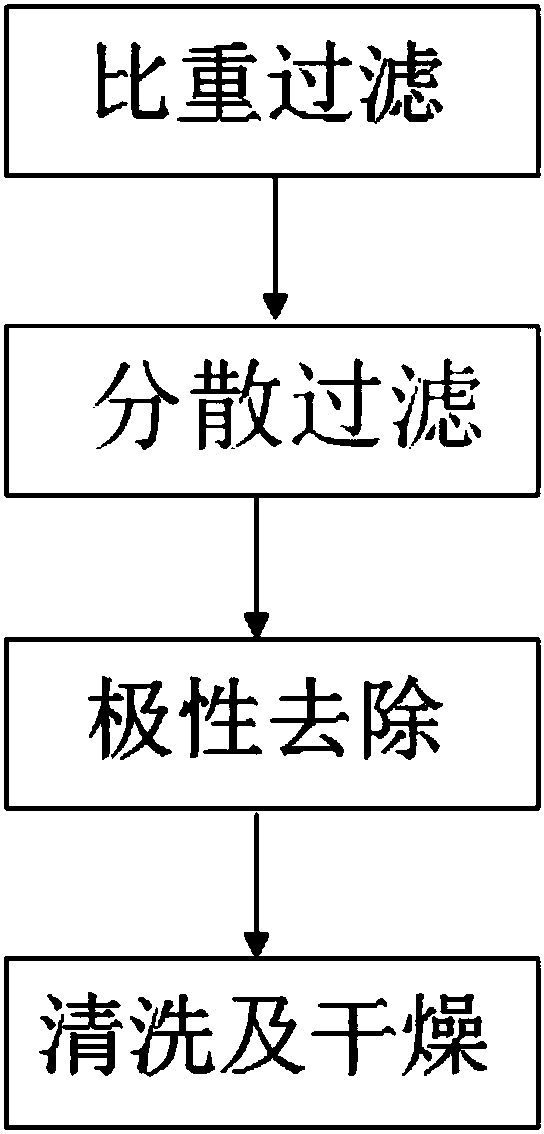

[0049] This embodiment provides a purification method of siliceous spongy spicules, which is carried out by using the purification system of Embodiment 1, and its process flow chart is as attached figure 1 As shown, it specifically includes the following steps:

[0050] Step 1: specific gravity filtration: the original siliceous sponge bone needle (fresh sponge) is placed between the first specific gravity filter screen and the second specific gravity filter screen of the specific gravity filter device, and adding a concentration of 10% in the specific gravity filter tank Soak in hydrogen oxide aqueous solution for 12 hours to soften the original siliceous spongy spicules and precipitate internal impurities, and according to the difference in specific gravity, make the impurities with larger specific gravity go down and be located under the second specific gravity filter screen; make the specific gravity Smaller impurities float upwards and are located on the first specific gr...

Embodiment 3

[0056] This example provides a method for purifying siliceous spicules of the present invention. Compared with Example 2,

[0057] In step 1, adding a concentration of 100% hydrogen peroxide solution to the specific gravity filter tank and soaking for 0.5 hours;

[0058] In step 2, add a hydrogen peroxide aqueous solution with a concentration of 100% to the dispersion filter tank body, stir the stirring blade at a speed of 1500 rpm, and stir and disperse for 10 minutes;

[0059] In step 3, dry the siliceous spongy spicules treated in step 2 in a vacuum oven at 150°C for 4 hours, and dry the siliceous spongy spicules from which the polar groups have been removed in a vacuum oven at 40°C for 24 hours;

[0060] In step 4, dry in a blast oven at 70°C until the water content is lower than 0.01%, and the rest of the conditions are the same.

[0061] The obtained purified siliceous spongy spicules are analyzed by an energy spectrum analyzer (EDS), and the purity is 100%. Observed b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com