Preparation method of self-insulating wallboard

A self-insulation and wall panel technology, applied in the field of building materials, can solve problems such as poor thermal insulation performance of thermal insulation walls, achieve thermal insulation effect, improved compressive performance, improved mechanical performance and thermal insulation performance, good mechanical performance and insulation. The effect of thermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

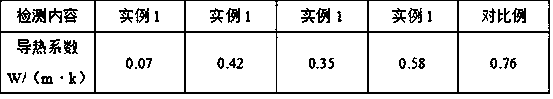

Examples

example 1

[0024]Mix coal gangue and fly ash in a grinder at a mass ratio of 7:2, and add zeolite 0.4 times the mass of gangue to the grinder, mix and grind for 45 minutes to obtain a mixture, mix the mixture and flux by mass Mix it in a blender at a ratio of 7:1, stir and mix for 30 minutes at a speed of 280r / min to obtain a sintered material, extrude the sintered material to obtain a billet, and dry the billet at a temperature of 90°C until the billet After the water content is 4%, move the dried billet into the sintering furnace, raise the temperature in the furnace to 1100°C at a heating rate of 120°C / min, keep it warm for 120 minutes, cool it to room temperature with the furnace, and discharge the material to obtain coal gangue Brick; the gangue is divided into two equal parts to obtain the No. 1 gangue brick and the No. 2 gangue brick, and the No. 1 gangue brick is moved into the crusher for crushing, and the 260 mesh sieve is passed to obtain the No. 1 coal gangue brick particle, a...

example 2

[0026] Mix coal gangue and fly ash in a grinder at a mass ratio of 7:2, and add zeolite 0.4 times the mass of gangue to the grinder, mix and grind for 45 minutes to obtain a mixture, mix the mixture and flux by mass Mix it in a blender at a ratio of 7:1, stir and mix for 30 minutes at a speed of 280r / min to obtain a sintered material, extrude the sintered material to obtain a billet, and dry the billet at a temperature of 90°C until the billet After the water content is 4%, move the dried billet into the sintering furnace, raise the temperature in the furnace to 1100°C at a heating rate of 120°C / min, keep it warm for 120 minutes, cool it to room temperature with the furnace, and discharge the material to obtain coal gangue Brick; mix vitrified microbeads and silane coupling agent in a beaker at a mass ratio of 4:1, and add rubber emulsion 5 times the mass of vitrified microbeads into the beaker, and move the beaker into a digital speed measuring constant temperature magnetic st...

example 3

[0028] Mix coal gangue and fly ash in a grinder at a mass ratio of 7:2, and add zeolite 0.4 times the mass of gangue to the grinder, mix and grind for 45 minutes to obtain a mixture, mix the mixture and flux by mass Mix it in a blender at a ratio of 7:1, stir and mix for 30 minutes at a speed of 280r / min to obtain a sintered material, extrude the sintered material to obtain a billet, and dry the billet at a temperature of 90°C until the billet After the water content is 4%, move the dried billet into the sintering furnace, raise the temperature in the furnace to 1100°C at a heating rate of 120°C / min, keep it warm for 120 minutes, cool it to room temperature with the furnace, and discharge the material to obtain coal gangue Brick; the gangue is divided into two equal parts to obtain the No. 1 gangue brick and the No. 2 gangue brick, and the No. 1 gangue brick is moved into the crusher for crushing, and the 260 mesh sieve is passed to obtain the No. 1 coal gangue brick particle, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com