Aramid honeycomb-reinforced silicon-based heat insulating material and preparation method thereof

A kind of technology of aramid honeycomb and thermal insulation material, applied in the direction of coating, can solve the problem of low strength, and achieve the effect of improving reliability, improving structural stability and excellent ablation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] A method for preparing an aramid honeycomb reinforced silicon-based heat insulating material, the steps of the method comprising:

[0049] (1) Mix vinyl-terminated silicone oil, hydrogen-containing silicone oil and inhibitor, and stir evenly;

[0050] (2) Add white carbon black, silicon carbide and magnesium oxide to the mixture obtained in step (1), and stir evenly;

[0051] (3) catalyst is added in the system that step (2) obtains, and stir;

[0052] (4) adding chopped carbon fiber to the system obtained in step (3), and stirring evenly to obtain a rubber compound;

[0053] (5) Fill the rubber compound obtained in step (4) into the honeycomb holes of the aramid honeycomb, and cure under pressure at room temperature to obtain the aramid honeycomb-reinforced silicon-based heat insulating material.

[0054] In the described step (5), when the fluidity of the obtained sizing material is better, the sizing material is filled into the honeycomb holes of the aramid honeyco...

Embodiment

[0061] The use of aramid honeycomb reinforced silicon-based insulation material can improve the structural stability of the insulation material during the ablation process, and because the axial direction of the aramid honeycomb hole is perpendicular to the direction of the engine gas flow, it is beneficial to improve the resistance of the insulation material in the honeycomb hole. The ability to scour, thereby improving the ablation performance of the insulation material, thereby improving the thermal protection reliability of the insulation layer in the engine.

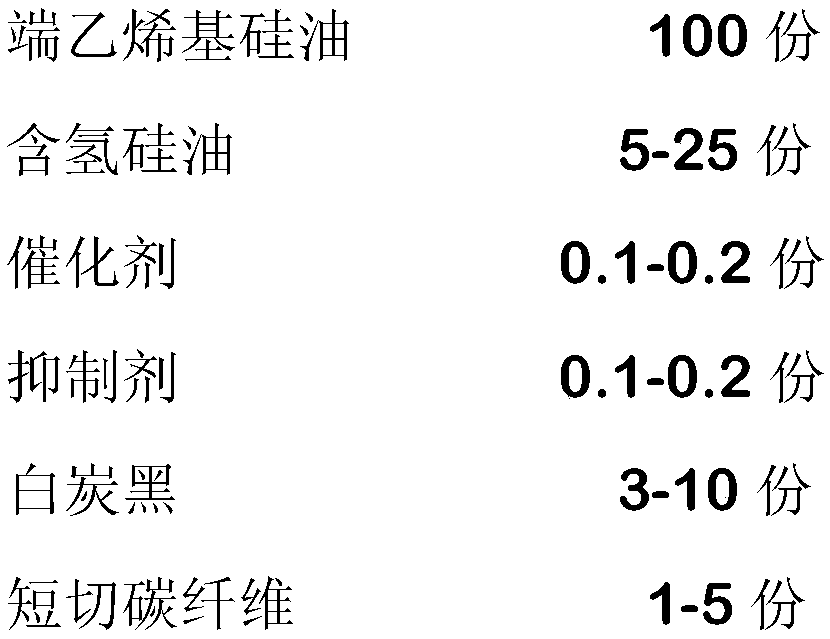

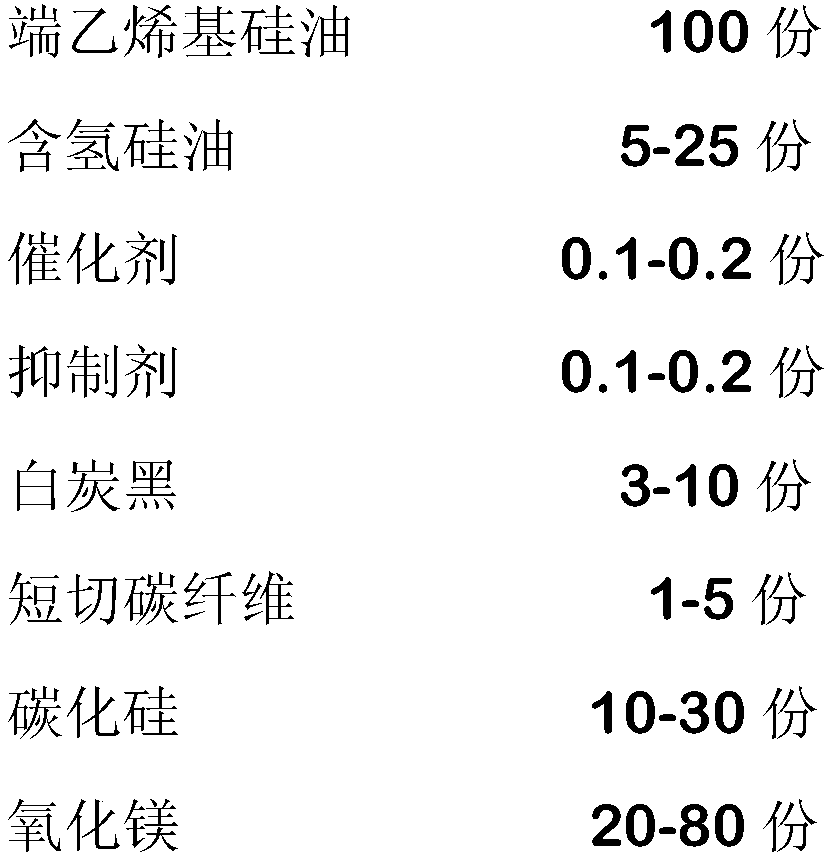

[0062] A silicon-based thermal insulation material reinforced with aramid fiber honeycomb, comprising aramid fiber honeycomb and rubber material, the rubber material is filled in the honeycomb holes of the aramid fiber honeycomb. Among them, calculated in parts by weight, weigh each component material in the rubber material according to the composition ratio, and press 1) terminal vinyl silicone oil, hydrogen-contain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com