Plant essential oil type insecticidal and insect repellent masterbatch, preparation method and application thereof

A technology of plant essential oil and master batch is applied in the field of preparation, plant essential oil type insecticidal and repellent master batch to achieve the effect of eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

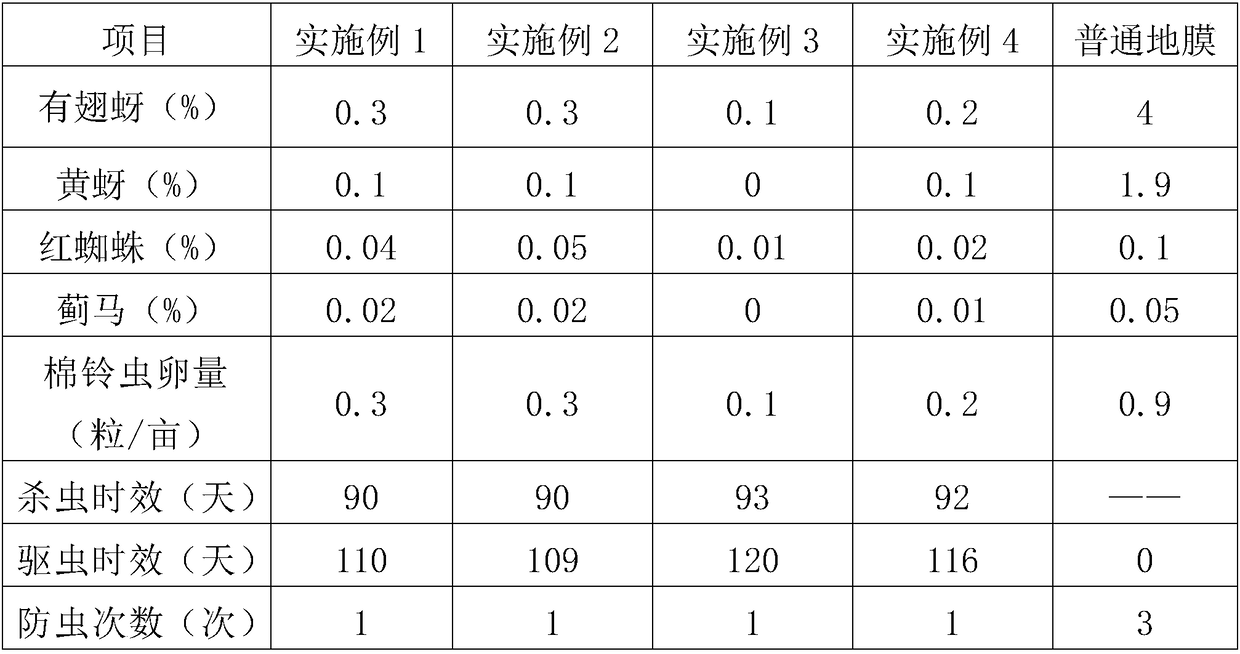

Embodiment 1

[0025] Example 1: Preparation of raw materials: Cypress essential oil: 0.8kg, rue essential oil: 0.3kg, litsea cubeba oil: 0.4kg, eugenol: 1kg, lemongrass essential oil: 0.8kg, piperonyl butoxide: 1kg, stearic acid Zinc: 0.8kg, PE wax: 3kg, antioxidant: 1.2kg, ultraviolet absorber: 1kg, active calcium carbonate: 8kg, barium sulfate: 15kg, LDPE (low density polyethylene): 66.7kg; Zinc stearate, PE wax, antioxidant, ultraviolet absorber, active calcium carbonate, barium sulfate, and LDPE are placed in a mixer for full mixing for later use, and sandy cedar essential oil, rue essential oil, litsea cubeba oil, eugenol, lemongrass essential oil, pepper Butyl butyl ether, placed in a stainless steel airtight container tank and mixed for 3 minutes, set aside, the mixed zinc stearate, PE wax, antioxidant, ultraviolet absorber, active calcium carbonate, barium sulfate, LDPE, etc. were divided into four parts, sandy ground Cypress essential oil, rue essential oil, litsea cubeba oil, euge...

Embodiment 2

[0026] Example 2: Preparation of raw materials: Star anise oil: 0.8kg, Artemisia annua essential oil: 0.3kg, spearmint essential oil: 0.4kg, thyme essential oil: 1kg, cinnamon oil: 0.8kg, piperonyl butoxide: 1kg, stearin Zinc acid: 0.8kg, PE wax: 3kg, antioxidant: 1.2kg, ultraviolet absorber: 1kg, active calcium carbonate: 8kg, barium sulfate: 15kg, LDPE (low density polyethylene): 66.7kg; , PE wax, antioxidant, ultraviolet absorber, talcum powder or active calcium carbonate, barium sulfate, and LDPE are placed in a mixer for full mixing for later use, and star anise oil, artemisia annua essential oil, spearmint essential oil, thyme essential oil , cinnamon oil, and piperonyl butyl ether were placed in a stainless steel airtight container and mixed for 3 minutes. For later use, the mixed zinc stearate, PE wax, antioxidant, ultraviolet absorber, active calcium carbonate, barium sulfate, and LDPE were divided into equal parts Four parts, star anise oil, Artemisia annua essential...

Embodiment 3

[0027]Example 3: Preparation of raw materials: Star anise oil: 1.5kg, Artemisia annua essential oil: 0.6kg, spearmint essential oil: 0.8kg, thyme essential oil: 1.5kg, cinnamon oil: 1.5kg, piperonyl butoxide: 1.5kg, Zinc stearate: 1.5kg, PE wax: 4kg, antioxidant: 2kg, ultraviolet absorber: 1.5kg, talcum powder: 10kg, barium sulfate: 20kg, LDPE (low density polyethylene): 53.6kg; Zinc, PE wax, antioxidant, ultraviolet absorber, talcum powder or active calcium carbonate, barium sulfate, and LDPE are placed in a mixer and fully mixed for later use. Star anise oil, artemisia annua essential oil, spearmint essential oil, thyme Essential oil, cinnamon oil, piperonyl butyl ether, placed in a stainless steel airtight container and mixed for 5 minutes, set aside, the mixed zinc stearate, PE wax, antioxidant, ultraviolet absorber, talcum powder, barium sulfate, LDPE, etc. Divide into four parts, star anise oil, artemisia annua essential oil, spearmint essential oil, thyme essential oil,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com