Hydrogen evolution electrode, preparation method and applications thereof

A hydrogen evolution electrode and electrode technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of insufficient hydrogen evolution activity of platinum-containing catalysts, and it is difficult to meet the needs of commercialization, so as to reduce platinum loading, improve activity, improve The effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Thick 1.7mm nickel foam (250g / cm 2 ) cut into an effective area of 4cm 2 After cleaning with acetone, hydrochloric acid and deionized water, electroplating in 0.1mol / L nickel chloride and 1mol / L ammonium chloride at a temperature of 40°C and an electroplating current of 1000mA / cm 2 , the electroplating time is 60s, the nickel foam after electroplating is aged in 0.1mol / L sodium chloride solution for 24h, after the electrode is cleaned, it is left to stand in a solution (pH=3) with a Pt content of 10ppm for 12h at a temperature of 40°C to obtain The platinum loading of the electrode is about 10ug / cm 2 , and then aged the electrode in 0.1mol / L sodium chloride for 24h, and dried it at 60°C for later use.

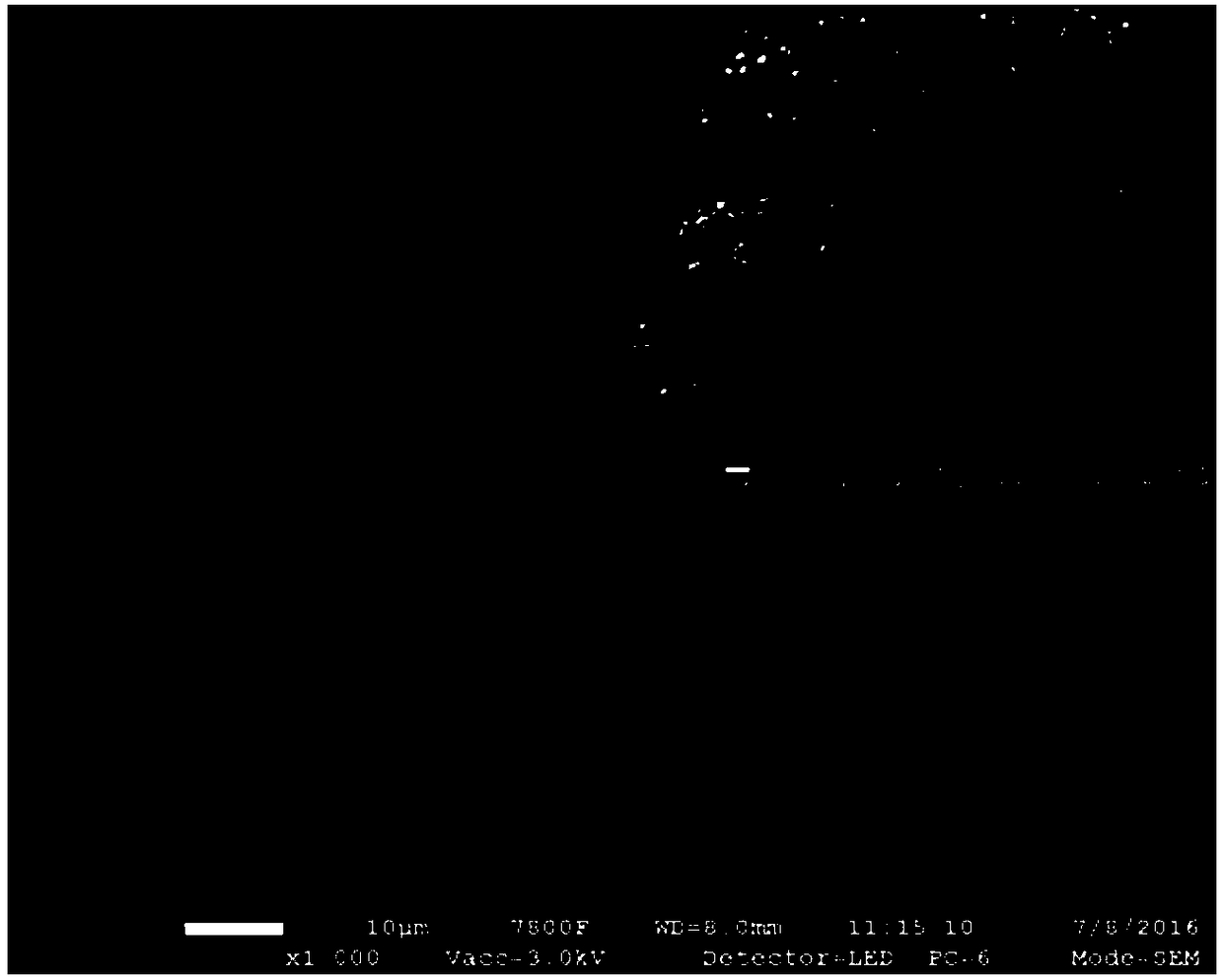

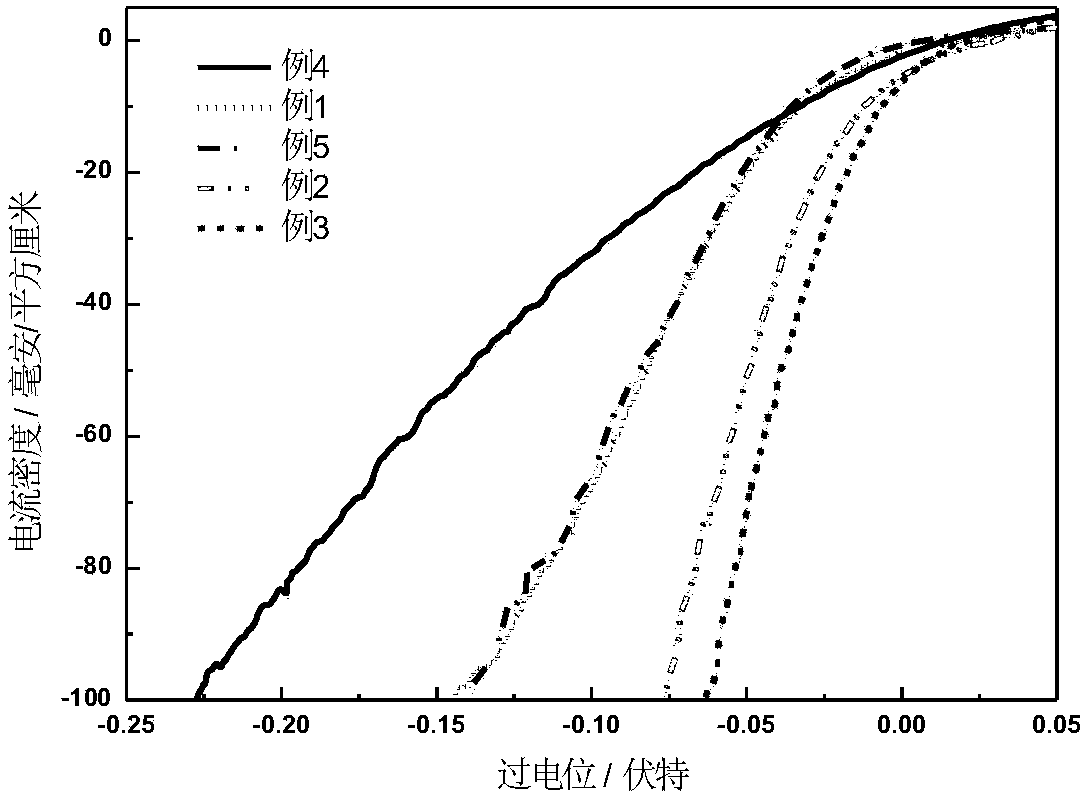

[0035] figure 2 The surface morphology of the prepared hydrogen evolution electrode can be seen from the figure that the uniform distribution of platinum nanoparticles on the surface of the hydroxide increases the active sites of the catalyst, from image 3 For th...

Embodiment 2

[0037] Increase the Pt content in Example 1 from 10ppm to 25ppm, and the platinum loading of the obtained electrode is about 25ug / cm2, and other conditions remain unchanged. Its hydrogen evolution performance see image 3 .

Embodiment 3

[0039] Increase the Pt content in Example 1 from 10ppm to 50ppm, and the platinum loading of the obtained electrode is about 50ug / cm2, and other conditions remain unchanged. Its hydrogen evolution performance see image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com