Method for extracting tea polyphenol in tea residues by using IL (ionic liquid) assisted ATPS (aqueous two phase system)

An ionic liquid, two-phase system technology, applied in the direction of tea extraction, tea, application, etc., can solve the problems of reducing the quality of tea polyphenols, difficult to popularize and apply, and high extraction temperature, and achieves improved binding force, high extraction efficiency, high extraction temperature. The effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

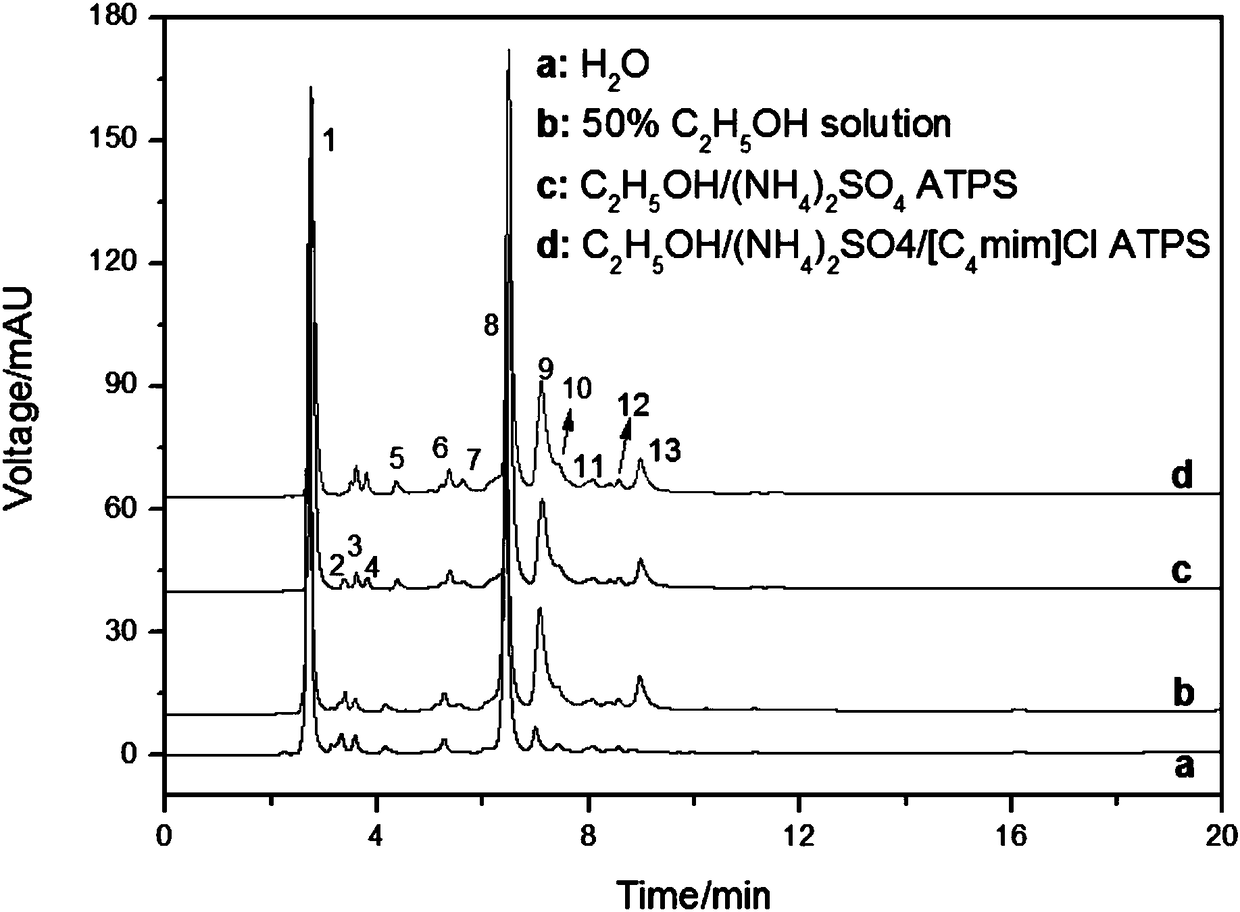

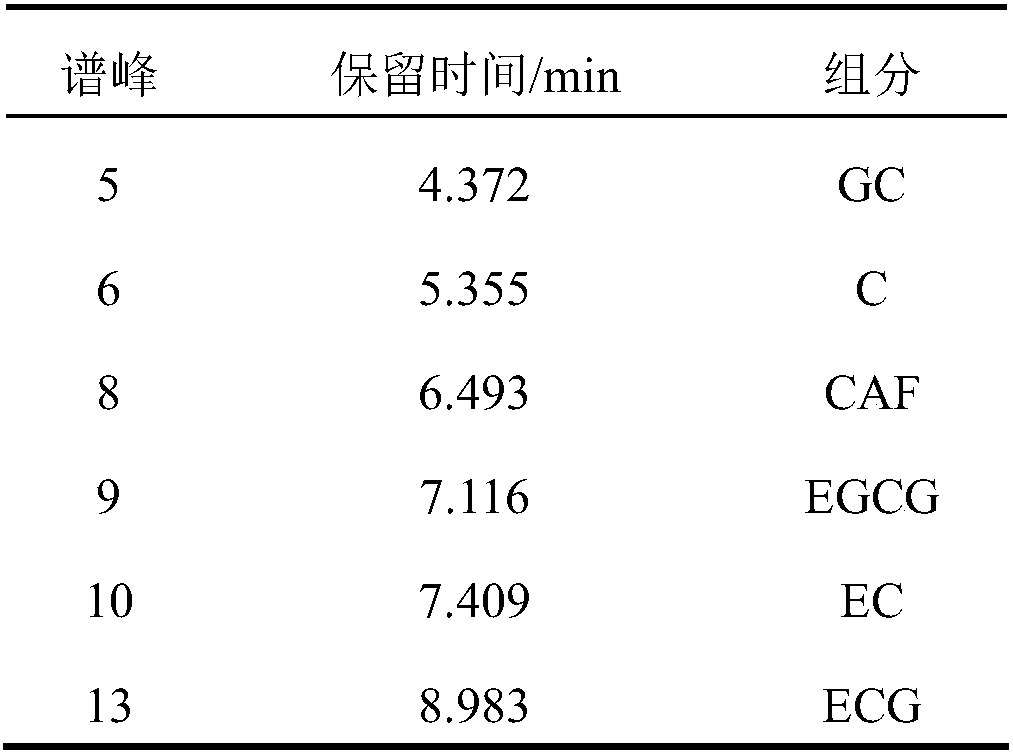

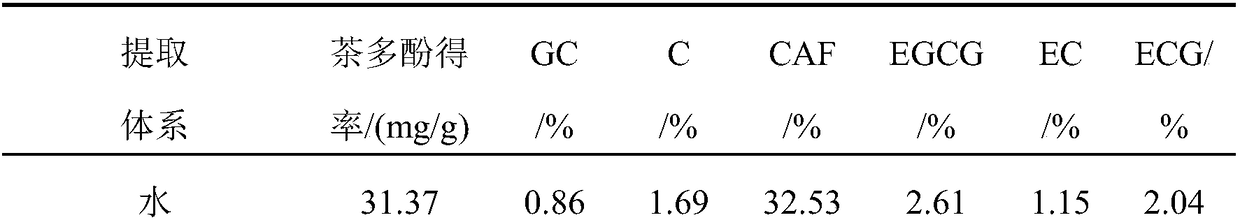

Embodiment 1

[0018] The method for extracting tea polyphenols in tea dregs by using an ionic liquid-assisted two-phase system is as follows:

[0019] Dry and pulverize the tea dregs, and collect 50-mesh tea powder.

[0020] Weigh 5 mL of 50% ethanol solution and 1.25 g of ammonium sulfate, and dissolve with ultrasonic assistance for 15 min to form an aqueous two-phase system. Add 0.143g of tea powder (the ratio of solid to liquid is 1:35), transfer to an ultrasonic extractor, and extract at 45°C for 10min at an ultrasonic power of 540w. After centrifugation, absorb the upper phase layer to obtain the tea polyphenol extract, wherein the tea polyphenol extraction yield is 42.11±0.55mg / g.

Embodiment 2

[0022] The method for extracting tea polyphenols in tea dregs by using an ionic liquid-assisted two-phase system is as follows:

[0023] Dry and pulverize the tea dregs, and collect 50-mesh tea powder.

[0024] Take by weighing volume fraction and be 50% ethanol solution 5mL, ammonium sulfate 1.25g, [C 4 mim] Cl ionic liquid 0.5g, ultrasonically assisted dissolution for 15min to form a two-phase aqueous system. Add 1.43g of tea powder (the ratio of solid to liquid is 1:35), transfer it to an ultrasonic extractor, and extract at 45°C for 5 minutes at an ultrasonic power of 540w. After centrifugal separation, absorb the upper phase layer to obtain the tea polyphenol extract, wherein the tea polyphenol extraction yield is 75.52±0.75mg / g.

Embodiment 3

[0026] The method for extracting tea polyphenols in tea dregs by using an ionic liquid-assisted two-phase system is as follows:

[0027] Dry and pulverize the tea dregs, and collect 50-mesh tea powder.

[0028] Take by weighing volume fraction and be 50% ethanol solution 5mL, ammonium sulfate 1.25g, [C 6 mim]Cl ionic liquid 2.5g, ultrasonically assisted dissolution for 15min, to form a two-phase aqueous system. Add 1.25g of tea powder (the ratio of solid to liquid is 1:40), transfer it to an ultrasonic extractor, and extract at 45°C for 10 minutes at an ultrasonic power of 540w. After centrifugation, absorb the upper phase layer to obtain a tea polyphenol extract, wherein the tea polyphenol extraction yield is 67.19±1.74mg / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com