Preparation method of high-adsorption heavy metal ion adsorbent

A technology of heavy metal ions and adsorbents, which is applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of low adsorption rate, achieve improved adsorption, improved adsorption, The effect of enhancing the ability to remove heavy metals in water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

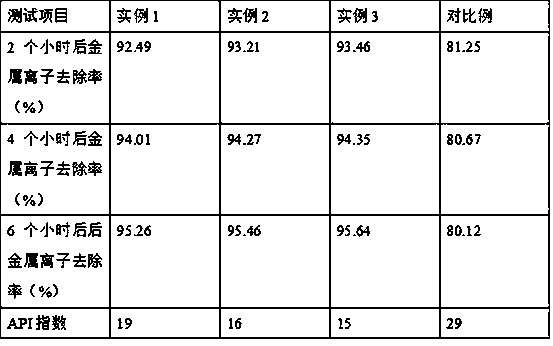

Examples

example 1

[0021]Weigh 100g of bentonite and grind for 6min to obtain bentonite powder. Mix bentonite powder and 10% sodium chloride solution with a mass fraction of 10% in a beaker and stir for 2 hours to obtain a mixture. Wash the mixture with deionized water 6min, then wash the mixture with a silver nitrate solution with a mass fraction of 10% to remove chloride ions, continue drying in an oven at 55°C for 10min, and grind through a 100-mesh sieve to collect the mixture powder, then put the mixture powder into 100 ℃ in a muffle furnace for 1 h, and naturally cooled to room temperature to obtain sodium-based sieved bentonite powder; weigh 18 g of cetyltrimethylammonium bromide and 4 g of sodium lauryl sulfate and place in a 0.8 L Stir and dissolve in a beaker of deionized water for 12 minutes, then add 35 g of sodium-based sieved bentonite powder to the beaker, and put it in a water bath at 70°C, continue mixing and stirring for 1 hour, and cool naturally to room temperature to obtain m...

example 2

[0023] Weigh 150g of bentonite and grind for 7min to obtain bentonite powder. Mix bentonite powder and 10% sodium chloride solution with a mass fraction of 10% in a beaker and stir for 3 hours to obtain a mixture. Wash the mixture with deionized water 7min, then wash the mixture with a silver nitrate solution with a mass fraction of 10% to remove chloride ions, continue drying in an oven at 65°C for 11min, and grind through a 100-mesh sieve to collect the mixture powder, then put the mixture powder into a 110 Activate in a muffle furnace at ℃ for 1.5h, and cool naturally to room temperature to obtain sodium-based sieved bentonite powder; weigh 20g of cetyltrimethylammonium bromide and 5g of sodium lauryl sulfate and place in a 0.9 Stir and dissolve in a beaker of deionized water for 14min, then add 45g of sodium-based sieved bentonite powder to the beaker, put it in a water bath at 80°C, continue mixing and stirring for 1.5h, and cool naturally to room temperature to obtain a m...

example 3

[0025] Weigh 200g of bentonite and grind for 8min to obtain bentonite powder. Mix bentonite powder and 10% sodium chloride solution with a mass fraction of 10% in a beaker and stir for 4 hours to obtain a mixture. Wash the mixture with deionized water 8min, and then wash the mixture with a silver nitrate solution with a mass fraction of 10% to remove chloride ions, continue to dry in an oven at 75°C for 12min, and grind through a 100-mesh sieve to collect the mixture powder, and then put the mixture powder into a 120 ℃ in a muffle furnace for 2 hours, and naturally cooled to room temperature to obtain sodium-based sieved bentonite powder; weigh 24g of cetyltrimethylammonium bromide and 6g of sodium lauryl sulfate and place in a 1.0L Stir and dissolve in a beaker of deionized water for 16 minutes, then add 55 g of sodium-based sieved bentonite powder to the beaker, and put it in a water bath at 90°C, continue mixing and stirring for 2 hours, and cool naturally to room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com