Preparation method of modified mycelium adsorbent and adsorption method for anionic pollutants

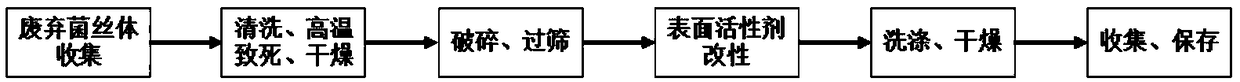

A technology of adsorbent and mycelium, which is applied in the preparation of modified mycelium adsorbent and the field of adsorption of anionic pollutants, which can solve the problems of unsatisfactory adsorption effect, low specific surface area of original mycelium, and low density of functional groups. , to achieve the effects of wide sources of mycelium, realization of resource utilization, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment provides a method for preparing a mycelium modified adsorbent, which is as follows: expand the cultivation in the laboratory to obtain Aspergillus versicolor mycelium balls, rinse off the impurities on the surface with clean water, crush and sieve after freeze-drying, pass through 60 Mesh sieve to obtain mycelium powder, weigh 2g of mycelium powder, mix mycelium powder with 100mL 1.5% cetyltrimethylammonium bromide solution, shake at 30°C and 150r / min for 24h, Filter and wash with copious amounts of deionized water until AgNO 3 The solution does not detect Br — , collected, freeze-dried and ground through a 60-mesh sieve to obtain a modified adsorbent. The specific surface area of mycelium powder before and after modification is 1.50, 2.03m 2 / g, the SEM pictures of mycelium powder before and after modification are shown in the attached figure 2 .

Embodiment 2

[0027] This embodiment provides a method for preparing a mycelium modified adsorbent, specifically: the yeast collected from a brewery is rinsed with clean water to remove impurities on the surface, crushed and sieved after freeze-drying, and passed through a 60-mesh sieve. Obtain mycelium powder; weigh 1g of mycelium powder into 150mL 1.0% cetyltrimethylammonium bromide solution, shake at 30°C 150r / min for 24h, filter to obtain mycelium powder, and use deionized Wash the filtered mycelium powder with water until AgNO 3 No Br- was detected in the solution, it was collected, freeze-dried, and ground through a 60-mesh sieve to obtain a modified adsorbent.

Embodiment 3

[0029] This embodiment provides a method for preparing a mycelium modified adsorbent, specifically: washing the collected Aspergillus versicolor mycelia balls with clean water to remove impurities on the surface, crushing and sieving after freeze-drying, and passing through a 60-mesh sieve , to obtain mycelium powder, weigh 1g of mycelium powder, mix the weighed mycelium powder with 100mL 1.5% cetyltrimethylammonium bromide solution, and mix at a temperature of 30°C with a speed of 150r / min Stir at high speed for 24h, filter, and wash with plenty of deionized water until AgNO 3 No Br- was detected in the solution, it was collected, freeze-dried and ground through a 60-mesh sieve to obtain a modified adsorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com