Gold cyaniding leaching aided agent and application thereof in gold cyanide leaching process

A technology of cyanide leaching and leaching aid, applied in the application field of leaching aid and cyanide gold leaching process, can solve the problem that the ore is not very targeted, so as to improve the cyanidation effect, improve the environment, and improve the The effect of leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

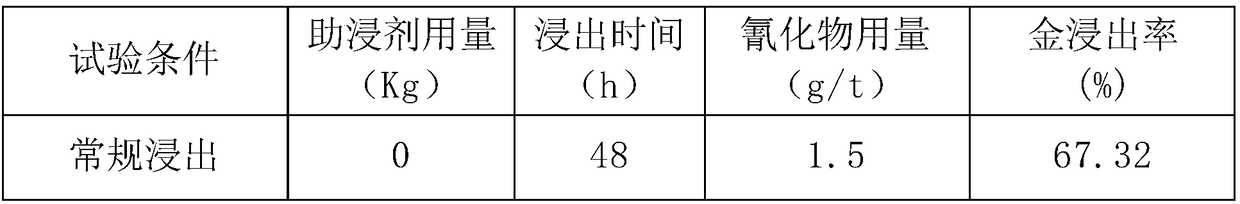

[0013] The test ore is a gold dressing tailing in Dandong, Liaoning. The gold grade in the tailings is 1.7g / t, and the gold mainly occurs in the quartz gangue. Grind the ore until -0.074mm accounts for more than 90%, prepare the pulp according to the liquid-solid mass ratio of 2:1, add quicklime to make the pH value of the pulp to 11.5, and then add the leaching aid (7 parts of ammonium fluoride, 1 part of lead nitrate , 2 parts of hydrogen peroxide) 2Kg / t, stirred for 4 hours, then added sodium cyanide 1Kg / t, stirred for 36 hours until the end of leaching. The test result of embodiment 1, see table 1.

[0014] Table 1 Test results (%) of Example 1.

[0015]

[0016]

Embodiment 2

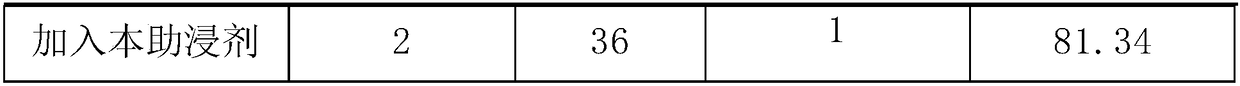

[0018] The test ore is a gold mine containing copper and arsenic sulfide. The raw ore contains 2.4g / t gold, 0.1% copper and 0.2% arsenic. The gold ore is mainly natural gold, which is closely related to sulfide, and the distribution rate of gold in chalcopyrite and arsenopyrite is more than 70%. Grind the ore until -0.074mm accounts for more than 95%, prepare the pulp according to the liquid-solid mass ratio of 2:1, add quicklime to adjust the pH value of the pulp to 12, and then add the leaching agent (6 parts of ammonium fluoride, 3 parts of lead nitrate , 1 part of hydrogen peroxide) 2Kg / t, stirred for 4 hours, then added sodium cyanide 1.5Kg / t, stirred for 48 hours until the end of leaching. The test result of embodiment 2, see table 2.

[0019] Table 2 Test results (%) of Example 2.

[0020]

Embodiment 3

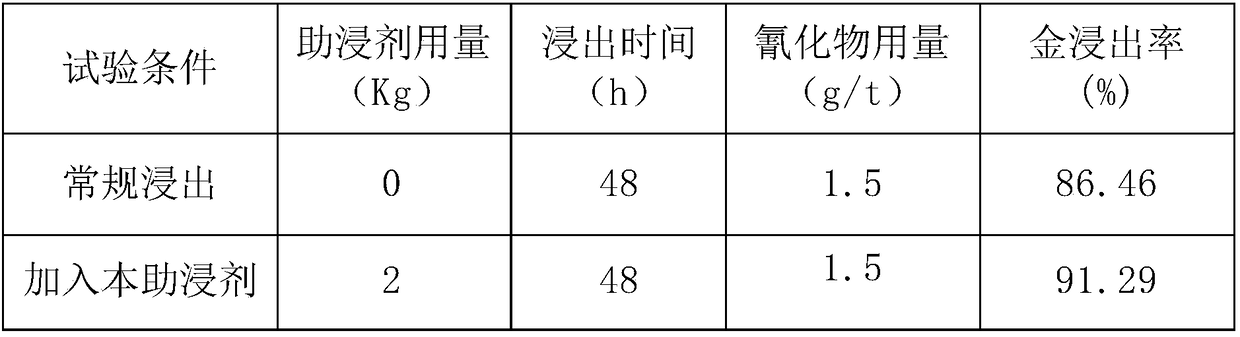

[0022] The test ore is a gold-bearing tailing in Inner Mongolia. The gold grade in the tailings is 2.1g / t, basically does not contain other non-ferrous metal elements, and the gold mainly occurs in the quartz gangue. Grind the ore until -0.074mm accounts for more than 90%, prepare the pulp according to the liquid-solid ratio of 2:1, add quicklime to make the pH value of the pulp to 11, and then add the leaching aid (8 parts of ammonium fluoride, 1 part of lead nitrate, 1 part of hydrogen peroxide) 2Kg / t, stirred for 4 hours, then added sodium cyanide 2Kg / t, stirred for 48 hours until the end of leaching. The test result of embodiment 3, see table 3.

[0023] Table 3 Test results (%) of Example 3.

[0024]

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com