Preparation method of tableware disinfectant

A disinfectant and tableware technology, applied in the direction of disinfectants, botany equipment and methods, chemical instruments and methods, etc., can solve problems such as human hazards, achieve low surface and interfacial tension, good detergency, and improve the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

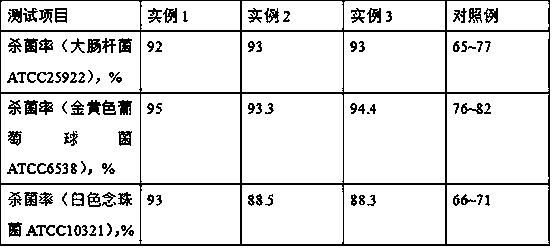

Examples

preparation example Construction

[0022] A kind of preparation method of tableware disinfectant, this preparation method comprises the steps:

[0023] (1) According to the mass ratio of 7~8:2~3:0.01~0.02, mix soluble starch, lauryl alcohol, and catalyst, stir at 110~120°C, 200~300r / min for 1~2h, and vacuum Incubate at a temperature of 0.01~0.03MPa for 1~2h, adjust the pH value to 8~9, wait to cool to room temperature, filter, and obtain the filter residue, according to the mass ratio of 1:3~4, mix the filter residue and hydrogen peroxide for 1~2h, filter , to obtain a decolorized product, wash the decolorized product with ethanol for 2 to 3 times, and dry it at a temperature of 50 to 60 ° C to obtain a dried product for subsequent use;

[0024] (2) Dry the orange peel at a temperature of 60-70°C, crush it, pass through a 30-40 mesh sieve to obtain the sieved product, and mix and degrease the sieved product and petroleum ether according to the mass ratio of 1:5-6. Filtrate, separate the filtrate and degreased ...

Embodiment 1

[0029] The catalyst is alumina.

[0030] The extract is obtained by crushing the orange peel to obtain a crushed product. The crushed product and petroleum ether are mixed at a mass ratio of 1:7, and extracted at a temperature of 60°C and 25 r / min for 25 minutes to obtain an extract.

[0031] The solid phase reagent is calcium carbonate.

[0032] A kind of preparation method of tableware disinfectant, this preparation method comprises the steps:

[0033] (1) According to the mass ratio of 7:2:0.01, mix soluble starch, lauryl alcohol and catalyst, stir at a temperature of 110°C and 200r / min for 1h, keep warm for 1h at a vacuum of 0.01MPa, and adjust the pH value to 8 , after cooling to room temperature, filter to obtain the filter residue, according to the mass ratio of 1:3, mix the filter residue and hydrogen peroxide for 1 hour for decolorization, filter to obtain the decolorized product, wash the decolorized product twice with ethanol, and dry it at a temperature of 50°C. ...

Embodiment 2

[0039] The catalyst is alumina.

[0040] The extraction solution is obtained by crushing the orange peel to obtain a crushed product. The crushed product and petroleum ether are mixed at a mass ratio of 1:8, and extracted at a temperature of 70°C and 30 r / min for 30 minutes to obtain an extract.

[0041] The solid phase reagent is calcium bicarbonate.

[0042] A kind of preparation method of tableware disinfectant, this preparation method comprises the steps:

[0043] (1) According to the mass ratio of 8:3:0.02, mix soluble starch, lauryl alcohol, and catalyst, stir at 120°C and 300r / min for 2h, keep warm at a vacuum of 0.03MPa for 2h, and adjust the pH value to 9 , after cooling to room temperature, filter to obtain the filter residue, according to the mass ratio of 1:4, mix the filter residue and hydrogen peroxide for 2 hours for decolorization, filter to obtain the decolorized product, wash the decolorized product with ethanol three times, and dry it at a temperature of 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com