A sesame defoliation and ripening agent and its application method

An application method and a ripening agent technology, which are applied in the field of sesame defoliation and ripening treatment, can solve the problems of affecting the cleanliness and commerciality of seeds, not conforming to the growth and development rules of sesame, and the difficulty of uniform harvesting of sesame, so as to facilitate later harvesting , Reduce the effect of poor seed cleanliness and reduce the difficulty of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Formula (weight ratio): thiadizuron 10%, sodium bicarbonate 11%, methyl jasmonate 1%, sodium butylnaphthalene sulfonate 10%, salt 0.2%, emulsified silicone oil 0.2%, and the balance is water.

[0030]Preparation method: add sodium bicarbonate, thiadizuron and methyl jasmonate in sequence to some water and mix well, grind in a wet pulverizer for 1.0-1.5 hours, then add sodium butylnaphthalene sulfonate, table salt, emulsified silicone oil and the rest water, after stirring, coarsely grind and finely grind, so that the particle size is less than 5 microns, and the finished product can be obtained. After diluting with water, it has good suspension and adsorption properties, and can be directly used as a spray liquid.

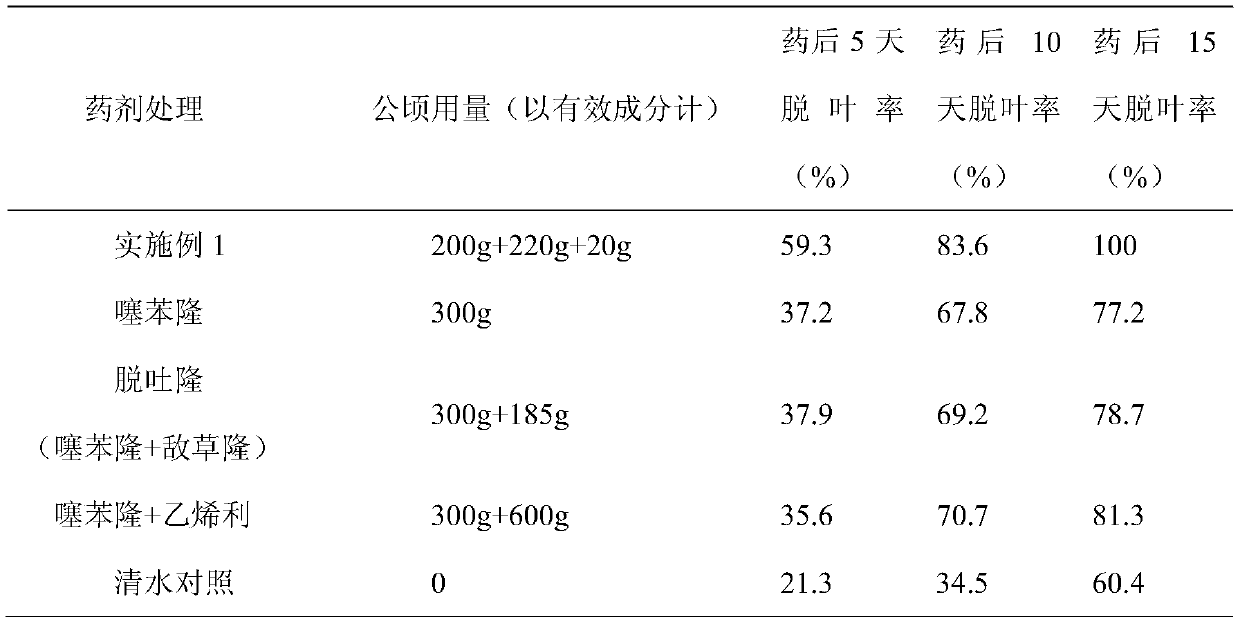

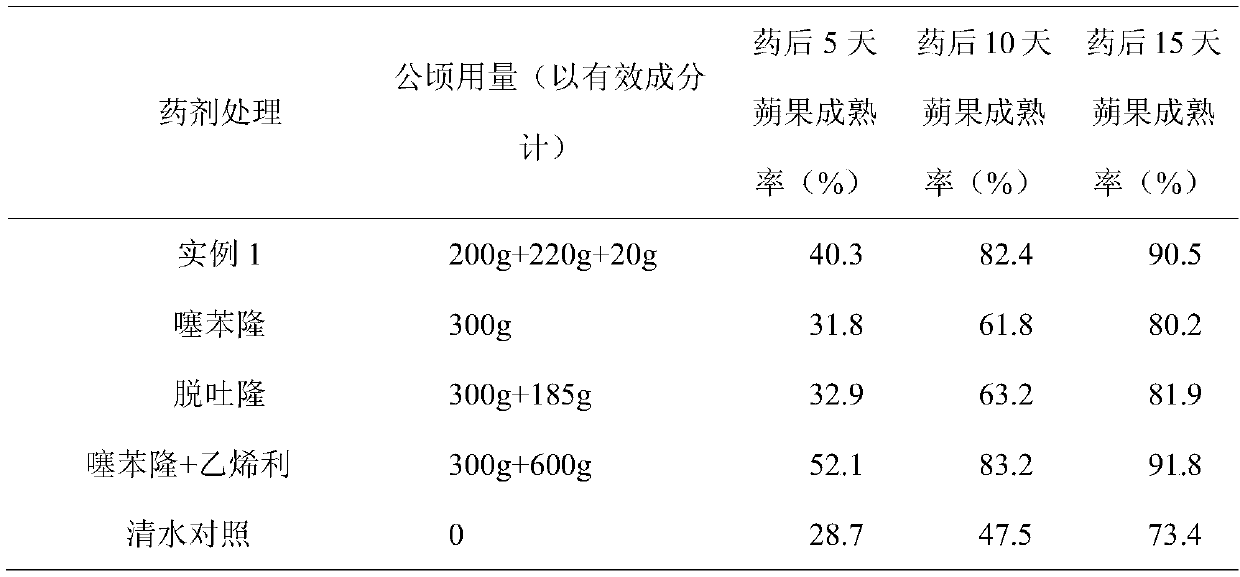

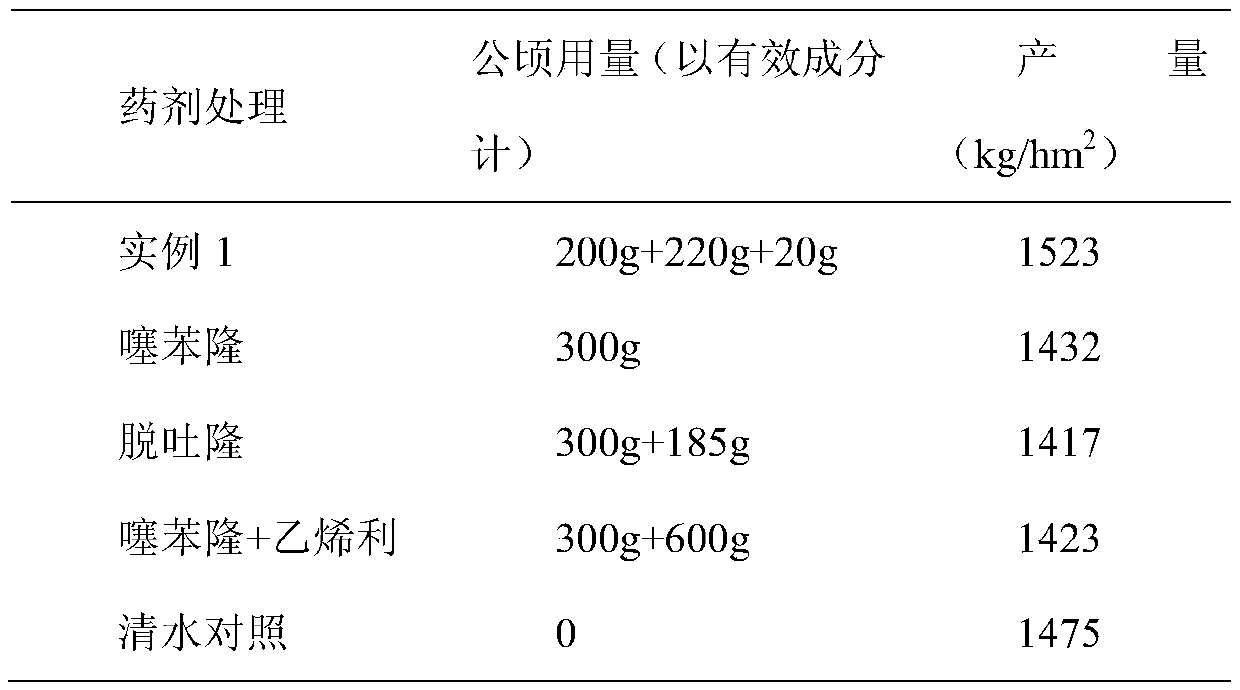

[0031] The product of Example 1 of the present invention was used for field test demonstration, and the test was carried out in Lingang Experimental Field, Jinan City, Shandong Province in August 2016. The experiment adopts randomized block experimental des...

Embodiment 2

[0044] Formula (weight ratio): thiadiuron 10%, sodium bicarbonate 10%, methyl jasmonate 0.8%, sodium butylnaphthalene sulfonate 9%, salt 0.2%, emulsified silicone oil 0.2%, and the balance is water.

[0045] Preparation method: add thiadizuron, sodium bicarbonate and methyl jasmonate in sequence to some water and mix well, grind in a wet pulverizer for 1.0-1.5 hours, then add sodium butylnaphthalene sulfonate, table salt, emulsified silicone oil and the rest water, after stirring, coarsely grind and finely grind, so that the particle size is less than 5 microns, and the finished product can be obtained. After diluting with water, it has good suspension and adsorption properties, and can be directly used as a spray liquid.

Embodiment 3

[0047] Formula (weight ratio): thiadizuron 10%, sodium bicarbonate 9.5%, methyl jasmonate 1.2%, sodium butylnaphthalene sulfonate 11%, salt 0.2%, emulsified silicone oil 0.2%, and the balance is water.

[0048] Preparation method: add thiadizuron, sodium bicarbonate and methyl jasmonate in sequence to some water and mix well, grind in a wet pulverizer for 1.0-1.5 hours, then add sodium butylnaphthalene sulfonate, table salt, emulsified silicone oil and the rest water, after stirring, coarsely grind and finely grind, so that the particle size is less than 5 microns, and the finished product can be obtained. After diluting with water, it has good suspension and adsorption properties, and can be directly used as a spray liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com