Konjac glucomannan surgical suture and preparation method thereof

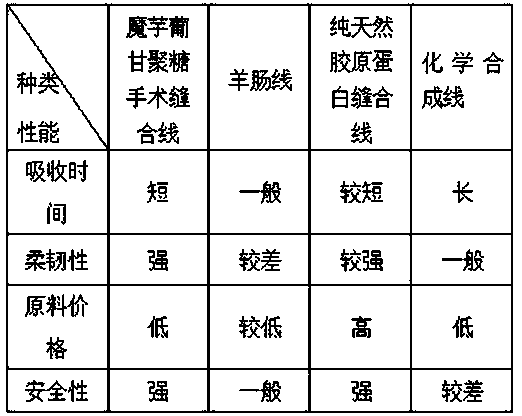

A technology of konjac glucomannan and surgical suture, which is applied in the field of medical devices, can solve the problems of high friction coefficient, complicated process, and high cost, and achieve the effects of good biocompatibility, low friction coefficient, and strong viscoelasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1, a kind of preparation method of konjac glucomannan surgical suture, comprises the following steps:

[0020] (1) Preparation of blend: Take the following components according to parts by weight: 6 parts of methacrylic acid, 35 parts of polyimide, 2 parts of orange peel pectin, 10 parts of carboxymethyl chitosan, sodium alginate 11 parts, 15 parts of konjac glucomannan, 3 parts of agar, 3 parts of fibroin, 5 parts of tea polyphenols, and 3 parts of glycerin were added to the reaction kettle, stirred at 60°C and 600r / min for 30min, and then Add 5 parts of sodium carboxymethylcellulose and stir for 1 hour at 60°C and 600 r / min, and finally add 2 parts of genipin to obtain a blend.

[0021] (2) Preparation of spinning dope: The blend in step (1) was ultrasonicated for 3 hours at room temperature to obtain a spinning dope.

[0022] (3) Preparation of absorbable sutures: degas the spinning stock solution obtained in step (2), spin on a micro-flow spinning machin...

Embodiment 2

[0023] Embodiment 2, a kind of preparation method of konjac glucomannan surgical suture, comprises the following steps:

[0024] (1) Preparation of blend: Take the following components according to parts by weight: 7 parts of methacrylic acid, 38 parts of polyimide, 4 parts of orange peel pectin, 12 parts of carboxymethyl chitosan, sodium alginate 13 parts, 17 parts of konjac glucomannan, 4 parts of agar, 5 parts of fibroin, 6 parts of tea polyphenols, and 5 parts of glycerin were added to the reaction kettle, stirred at 70°C and 600r / min for 30min, and then Add 6 parts of sodium carboxymethylcellulose and stir for 1-3 hours under the conditions of 70°C and 600 r / min, and finally add 3 parts of genipin to obtain a blend.

[0025] (2) Preparation of spinning dope: The blend in step (1) was ultrasonicated for 5 hours at room temperature to obtain spinning dope.

[0026] (3) Preparation of absorbable sutures: degas the spinning stock solution obtained in step (2), spin on a micr...

Embodiment 3

[0027] Embodiment 3, a kind of preparation method of konjac glucomannan surgical suture, comprises the following steps:

[0028] (1) Preparation of blend: Take the following components according to parts by weight: 8 parts of methacrylic acid, 40 parts of polyimide, 8 parts of orange peel pectin, 15 parts of carboxymethyl chitosan, sodium alginate 14 parts, 20 parts of konjac glucomannan, 5 parts of agar, 8 parts of fibroin, 10 parts of tea polyphenols, and 7 parts of glycerin were added to the reaction kettle, stirred at 80°C and 600r / min for 30min, and then Add 10 parts of sodium carboxymethylcellulose, stir for 3 hours at 80°C and 600 r / min, and finally add 3 parts of genipin to obtain a blend.

[0029] (2) Preparation of spinning dope: The blend in step (1) was ultrasonicated for 6 hours at room temperature to obtain spinning dope.

[0030] (3) Preparation of absorbable sutures: degas the spinning stock solution obtained in step (2), spin on a micro-flow spinning machine,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com