Preparation method and use method of nitrogen doped carbon catalyst for preparing vinyl chloride by acetylene hydrochlorination of fixed bed

A technology of acetylene hydrochlorination and nitrogen-doped carbon, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, hydrogen halide addition preparation, etc. It can solve the problems of polluting the environment, demanding conditions, and unfavorable mass production. Achieve the effects of simplifying the preparation process, reducing pollution, and avoiding doping steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

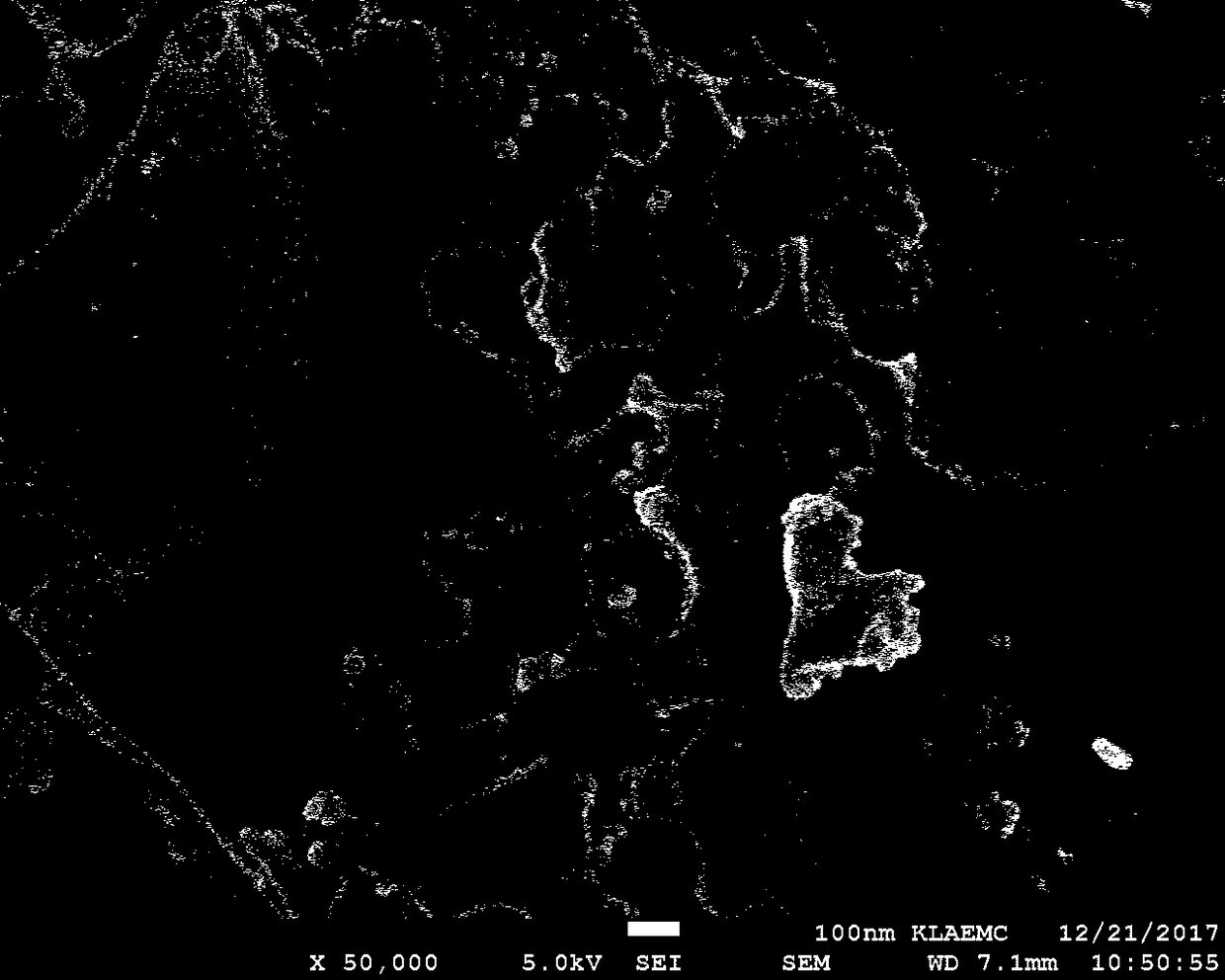

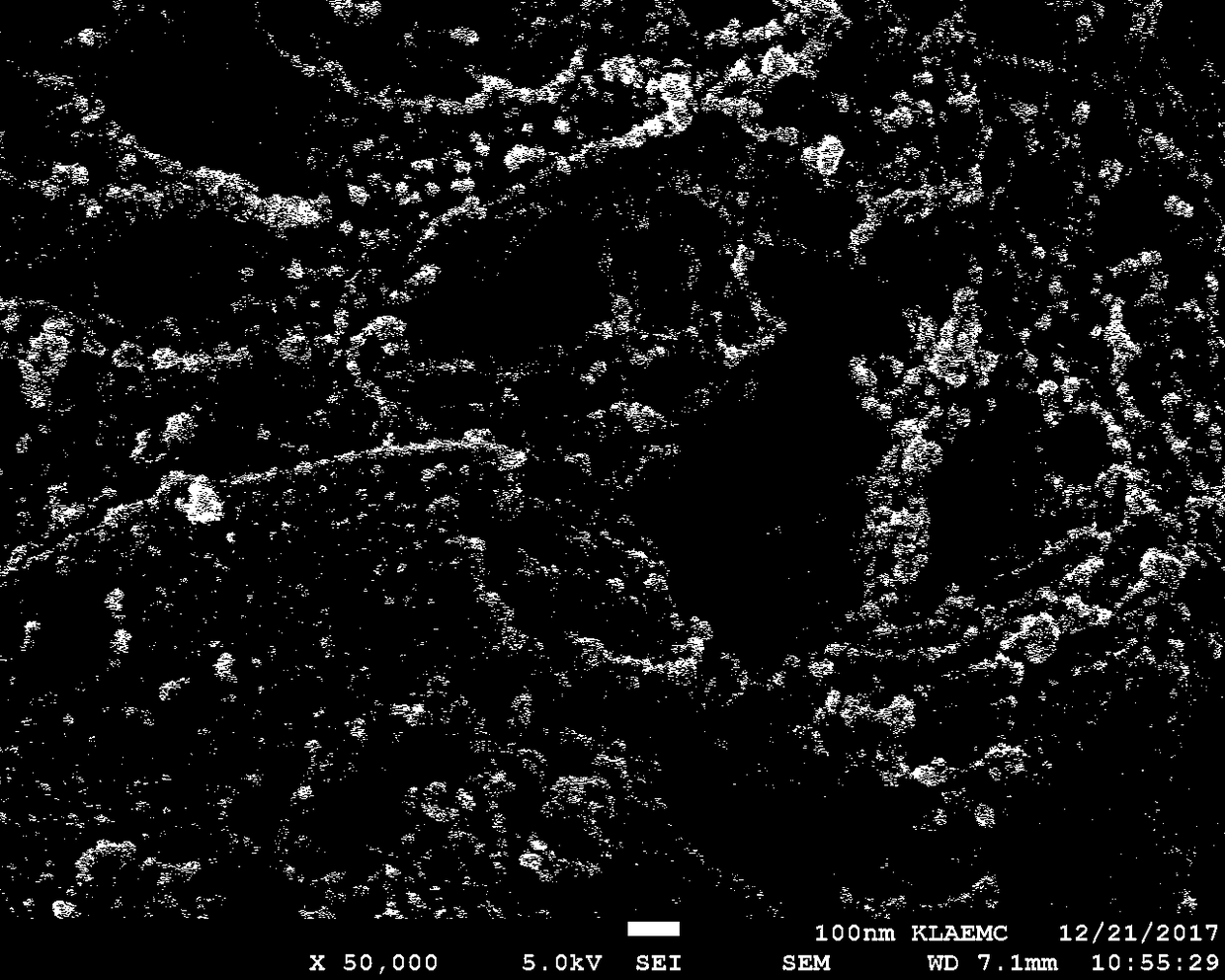

Image

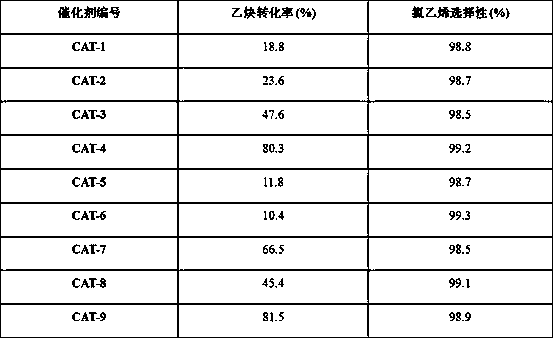

Examples

Embodiment 1

[0043] 1) Shred about 10g of silkworm cocoon shells, soak them in deionized water at 50°C for more than 6 hours to remove impurities and soluble inorganic salts in the silkworm cocoons, then filter and separate the samples, and wash them with deionized water for more than 5 times , and then dried at 100 °C to obtain sample A;

[0044] 2) Place sample A in a tube furnace, heat up to 250 °C in a flowing air atmosphere at a rate of 5 °C / min for pre-carbonization, and keep the temperature at 250 °C for 40 min to obtain sample B, in which air The volumetric space velocity is 180 h -1 , the constant temperature at a lower temperature of 250 ℃ is to avoid excessive oxidation of the surface groups of the material;

[0045] 3) Grind sample B into powder and place it in 5% dilute hydrochloric acid solution, stir at room temperature for 12 hours, then filter and separate the powder, wash with deionized water until neutral, and dry the obtained filter cake at 120 °C , that is, the nitro...

Embodiment 2

[0047] 1) Shred about 10g of silkworm cocoon shells, soak them in deionized water at 50°C for more than 6 hours to remove impurities and soluble inorganic salts in the silkworm cocoons, then filter and separate the samples, and wash them with deionized water for more than 5 times , and then dried at 100 °C to obtain sample A;

[0048] 2) Place sample A in a tube furnace, heat up to 350 °C in a flowing air atmosphere at a rate of 5 °C / min for pre-carbonization, and keep the temperature at 350 °C for 40 min to obtain sample B, in which air The volumetric space velocity is 180 h -1 , the constant temperature at a lower temperature of 350 ℃ is to avoid excessive oxidation of the surface groups of the material;

[0049] 3) Grind sample B into powder and place it in 5% dilute hydrochloric acid solution, stir at room temperature for 12 hours, then filter and separate the powder, wash with deionized water until neutral, and dry the obtained filter cake at 120 °C dry, the nitrogen-do...

Embodiment 3

[0051] 1) Shred about 10g of silkworm cocoon shells, soak them in deionized water at 50°C for 6 hours to remove impurities and soluble inorganic salts in the silkworm cocoons, then filter and separate the samples, and wash them with deionized water for more than 5 times. Then dry at 100°C to obtain sample A;

[0052] 2) Place sample A in a tube furnace, heat up to 350 °C in a flowing air atmosphere at a rate of 5 °C / min for pre-carbonization, and keep the temperature at 350 °C for 40 min to obtain sample B, in which air The volumetric space velocity is 180 h -1 ;

[0053] 3) Grind sample B into powder and place it in dilute hydrochloric acid solution, stir at room temperature for 12 hours, then filter and separate the powder with suction, wash with deionized water until neutral, and dry the obtained filter cake at 120 °C to obtain sample C ;

[0054] 4) Mix 3g of sample C with 3g of KOH powder, transfer the mixture to a tube furnace after fully grinding, in flowing N 2 Und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com