A programmable and modular pdms microfluidic chip mold system

A technology of microfluidic chips and programming modules, applied in the field of microfluidics, which can solve the problems of increasing processing costs and time, reducing processing efficiency, and complicated processing processes, and achieves the effects of saving experimental costs, simple device design, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

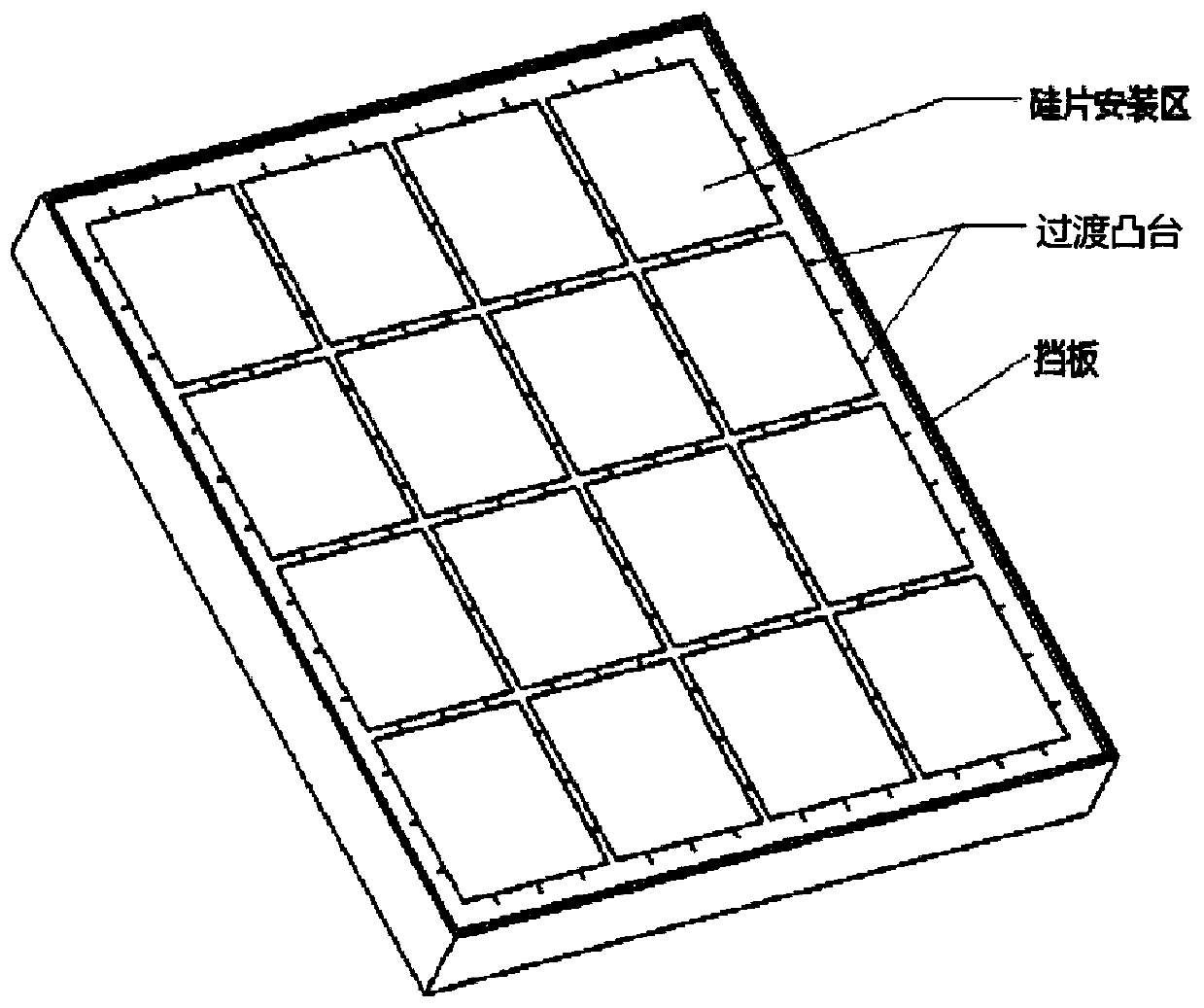

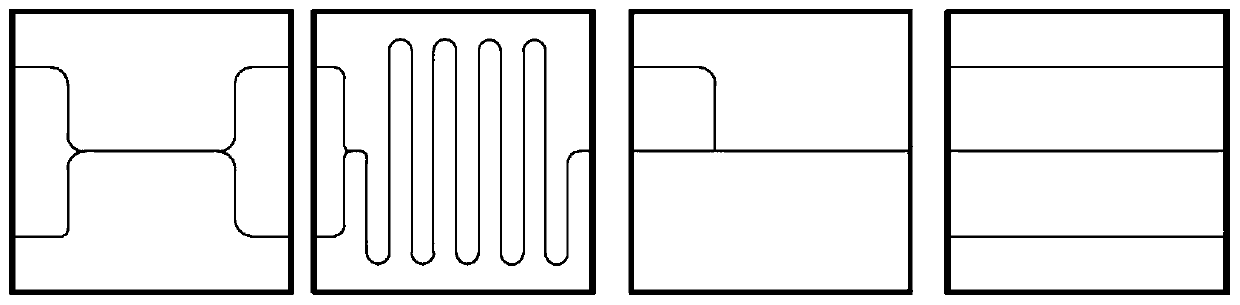

[0023] select image 3 The four-piece silicon wafer mold module in the middle is used for PDMS inversion, and its functions are H-shaped flow channel (for fluid extraction), fluid mixing, T-shaped flow channel (for droplet generation) and straight flow channel (for transition).

[0024] (1) put it in accordance with image 3 The sequence shown is mounted on the mold assembly platform,

[0025] (2) Pour the prepared PDMS prepolymer on the combined mold surface of the assembly platform,

[0026] (3) Put the platform on the heating plate and heat it until the PDMS is cured to complete the PDMS mold.

[0027] (4) Release the cured PDMS from the mold, and perform ultrasonic cleaning on it and a glass piece of the same size at the same time, and then use an ion surface treatment instrument for surface modification.

[0028] (5) Attach the PDMS to the glass slide to complete the sealing of the microchannel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com