SSZ-13 molecular sieve and preparation method thereof

A molecular sieve, ion exchanger technology, applied in the direction of crystalline aluminosilicate zeolite, can solve the problems of unsatisfactory thermal stability and hydrothermal stability, low density of strong acid centers, easy loss of acid centers, etc., to improve ion migration ability, high hydrothermal stability, the effect of increasing the crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

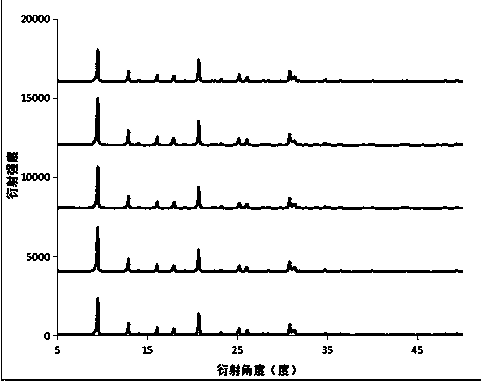

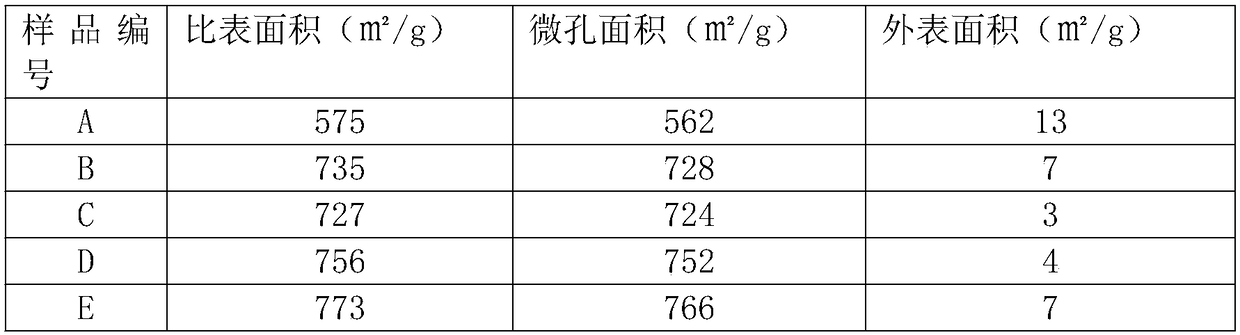

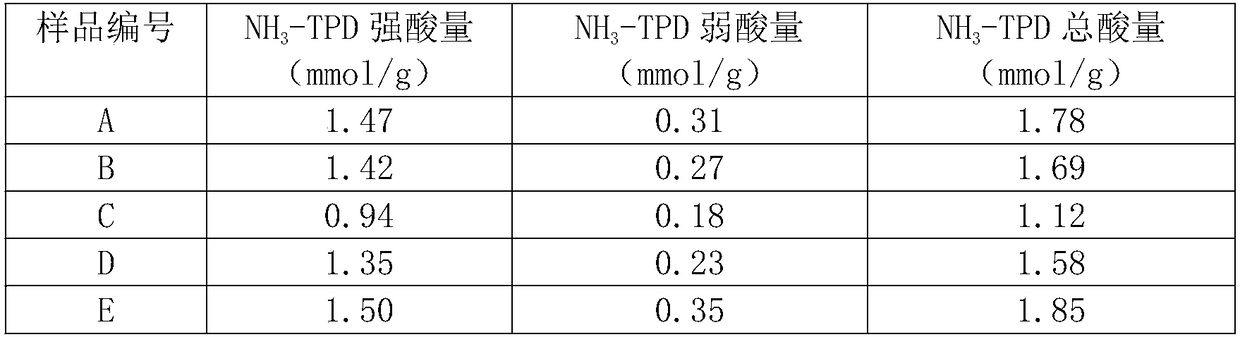

Image

Examples

Embodiment 1

[0035] Preparation and application of comparative samples:

[0036] 1) Gel synthesis: Add 1688 grams of 20% N,N,N-trimethyladamantyl ammonium hydroxide (template agent R2) into a beaker, and stir in a water bath at 25°C for 40 minutes. Add 560 grams of potassium hydroxide with a mass fraction of 25%, and then add 533.3 grams of sodium hydroxide with a mass fraction of 30%, and continue stirring. Add 1714.3 mass fraction of 35% alkaline silica sol, and stir for 80 min. Then add 266.56 grams of aluminum sulfate and 3098.4 grams of water to prepare the aqueous solution. Stir at 30°C for 6 hours to obtain a gel. Then ultrasonically disperse the gel in an ultrasonic cleaning machine for 20 minutes to prepare a uniform gel;

[0037] The molar ratio of the reaction materials is: SiO2 :Al 2 o 3 :K 2 O:Na 2 O:R2:H 2 O=1:0.04:0.1:0.2:0.2:35;

[0038] 2) High-temperature hydrothermal reaction: Transfer the homogeneous gel to a hydrothermal reaction kettle at 160°C, with a stirri...

Embodiment 2

[0042] 1) Gel synthesis: Dissolve 93.85 grams of amantadine hydrochloride (template agent R1) and 171.4 grams of barium hydroxide into 1356.2 grams of water, stir in a water bath at 20°C for 40 minutes, add 351.6 grams of 30% N, N, N- Trimethyladamantyl ammonium hydroxide (template agent R2), continue to stir. Add 560 grams of potassium hydroxide with a mass fraction of 20%, and then add 266.7 grams of sodium hydroxide with a mass fraction of 30%, and continue stirring. Add 1500 g of alkaline silica sol with a mass fraction of 40%, and stir for 100 min. Add the aqueous solution that the aluminum sulfate of 266.6 grams and 1362.9 grams of water are mixed with again. Stir at 20°C for 7 hours to obtain a gel. Then ultrasonically disperse the gel in an ultrasonic cleaning machine for 20 minutes to prepare a uniform gel;

[0043] The molar ratio of the reaction materials is: SiO 2 :Al 2 o 3 :K 2 O:Na 2 O:BaO:R 1 :R 2 :H 2 O=1:0.04:0.1:0.1:0.1:0.05:0.05:25;

[0044] 2) H...

Embodiment 3

[0048] 1) Gel synthesis: Dissolve 18.77 g of amantadine hydrochloride (template agent R1) and 102.8 g of barium hydroxide into 1454.6 g of water, stir in a water bath at 40°C for 30 min, add 253.2 g of 25% N, N, N-tri Methyladamantyl ammonium hydroxide (template agent R2), continue to stir. Add 746.7 grams of potassium hydroxide with a mass fraction of 30%, and then add 800 grams of sodium hydroxide with a mass fraction of 20%, and continue stirring. Add 1200 g of alkaline silica sol with a mass fraction of 50%, and stir for 120 min. Add the aqueous solution that the aluminum sulfate of 166.6 grams and 1992.8 grams of water are mixed with again. Stir at 40°C for 4 hours to obtain a gel. Then the gel was ultrasonically dispersed in an ultrasonic cleaning machine for 10 minutes to prepare a uniform gel;

[0049] The molar ratio of the reaction materials is: SiO 2 :Al 2 o 3 :K 2 O:Na 2 O:BaO:R 1 :R 2 :H 2 O=1:0.025:0.2:0.2:0.06:0.01:0.03:30;

[0050] 2) High-temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com