Blende structure Cu2MnSnS4 powder material and liquid phase preparation method thereof

A powder material and sphalerite technology, applied in chemical instruments and methods, inorganic chemistry, manganese compounds, etc., can solve the problems of difficult control of copper, manganese, tin and sulfur powder material components, high preparation costs, environmental pollution, etc., to achieve The effect of low cost, high production efficiency, and simple operation of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

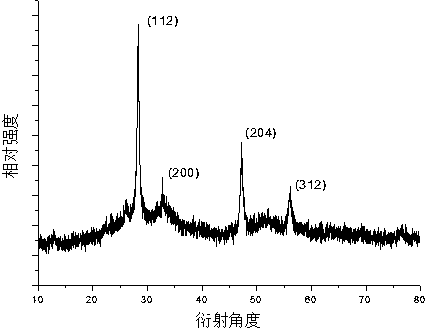

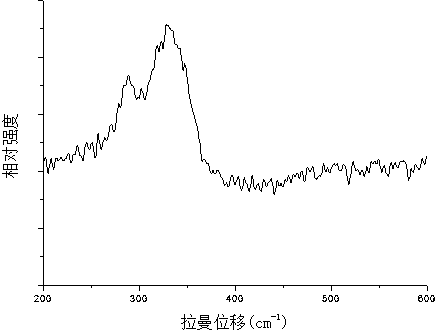

[0029] Mix choline chloride and urea evenly, heat to 80° C., stir for 1 hour, and cool to room temperature to obtain a deep eutectic solution. The molar ratio of choline chloride to solvent is 1:2. Weigh 4 mmol CuCl 2 • 2H 2 O, 2 mmol MnCl 2 • 4H 2 O, 2 mmol SnCl 4 • 5H 2 0. Put 8 mmol thiourea into a three-necked round-bottomed flask, add 35 ml of deep eutectic solution, and place it for 3-5 minutes to obtain a uniform milky white solution. Introduce nitrogen as a protective gas, and place the three-necked round-bottomed flask at a constant temperature Heated to 200 °C in an oil bath and kept for 4 h, then cooled to room temperature, washed with absolute ethanol and deionized water for 3 times, then filtered, and dried in a drying oven at 60 °C for 6 h to obtain a black powder .

Embodiment 2

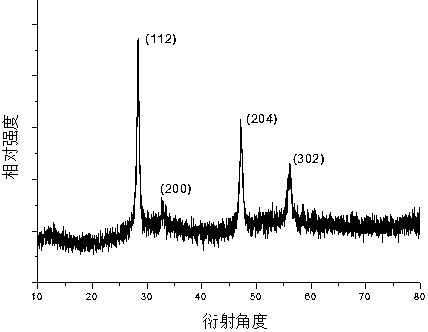

[0031] Choline chloride and urea were mixed uniformly, heated to 80 °C, stirred for 1 h, cooled to room temperature, and a deep eutectic solution was obtained. The molar ratio of choline chloride to solvent was 1:3. Weigh 4 mmol CuCl 2 • 2H 2 O, 2 mmol MnCl 2 • 4H 2 O, 2 mmol SnCl 4 • 5H 2 0. Put 8 mmol thiourea into a three-necked round-bottomed flask, add 35 ml of deep eutectic solution, and place it for 3-5 minutes to obtain a uniform milky white solution. Introduce nitrogen as a protective gas, and place the three-necked round-bottomed flask at a constant temperature Heated to 200 °C in an oil bath and kept for 4 h, then cooled to room temperature, washed with absolute ethanol and deionized water for 3 times, then filtered, and dried in a drying oven at 60 °C for 6 h to obtain a black powder .

Embodiment 3

[0033] Choline chloride and urea were mixed uniformly, heated to 80 °C, stirred for 1 h, cooled to room temperature, and a deep eutectic solution was obtained. The molar ratio of choline chloride to solvent was 1:2. Weigh 4 mmol CuCl 2 • 2H 2 O, 2 mmol MnCl 2 • 4H 2 O, 2 mmol SnCl 4 • 5H 20. Put 8 mmol thiourea into a three-necked round-bottomed flask, add 35 ml of deep eutectic solution, and place it for 3-5 minutes to obtain a uniform milky white solution. Introduce nitrogen as a protective gas, and place the three-necked round-bottomed flask at a constant temperature Heated to 180°C in an oil bath and kept for 6 h, then cooled to room temperature, washed three times with absolute ethanol and deionized water, then filtered, and dried in a drying oven at 60°C for 4 h to obtain a black powder .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com