Method for preparing AlN ceramic powder by carbothermal reduction nitridation method

A technology of ceramic powder and nitriding method, which is applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of hindering the reaction process, high pressure, high CO concentration, etc., and achieve increased production, small crystal grains, and reduced Effect of O content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] γ-Al with an average particle size of 20nm 2 o 3 AlN ceramic powder was synthesized by carbothermal reduction nitriding method in a nitrogen environment with activated carbon as raw material. The main steps include:

[0050] ①Ingredients: Weigh γ-Al according to the carbon content (the mass percentage of activated carbon in the mass percentage of the mixed powder) is 36% 2 o 3 Mix powder with activated carbon, place the weighed powder in a high-energy ball mill tank equipped with alumina balls, inject deionized water as the ball mill medium (the ratio of ball to material is 10:1, and the ratio of liquid to solid is 4:1) , with 300rpm ball milling for 5h, using a spray dryer to dry and granulate the slurry;

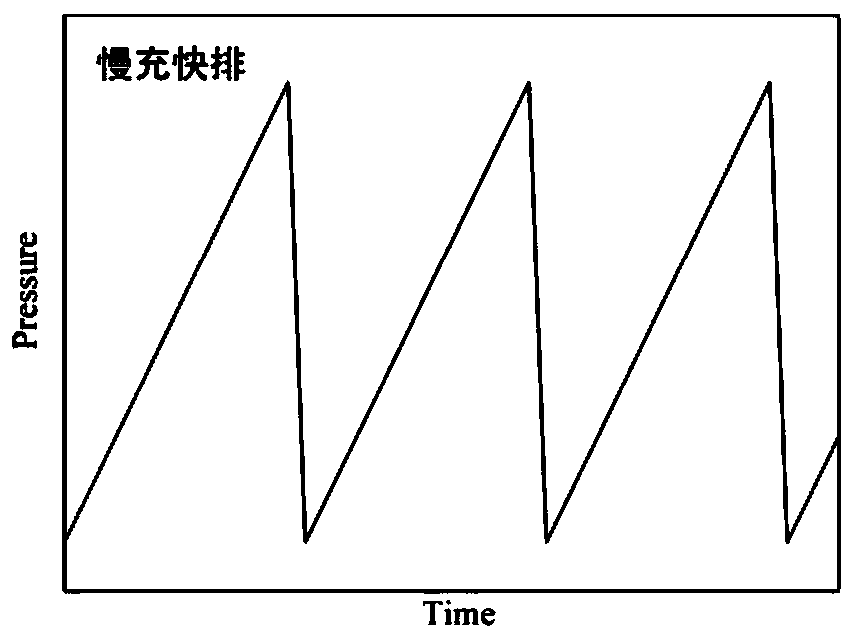

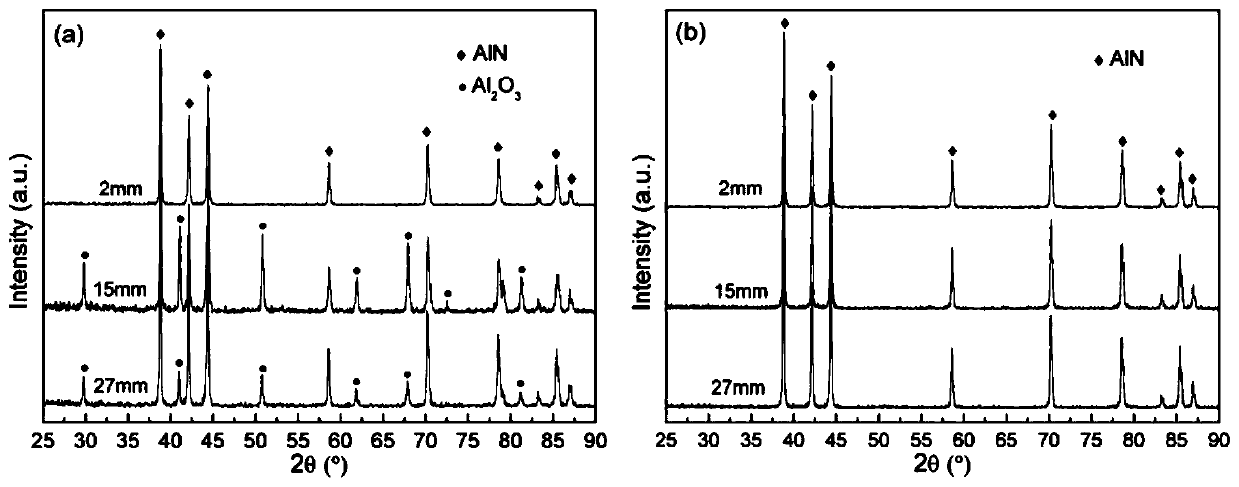

[0051] ②Charging and pulse air pressure control: Lay graphite paper around and at the bottom of the graphite material box, put the mixed powder obtained in step ① into the above graphite material box, the height of the mixed powder is 27mm, and place the graphit...

Embodiment 2

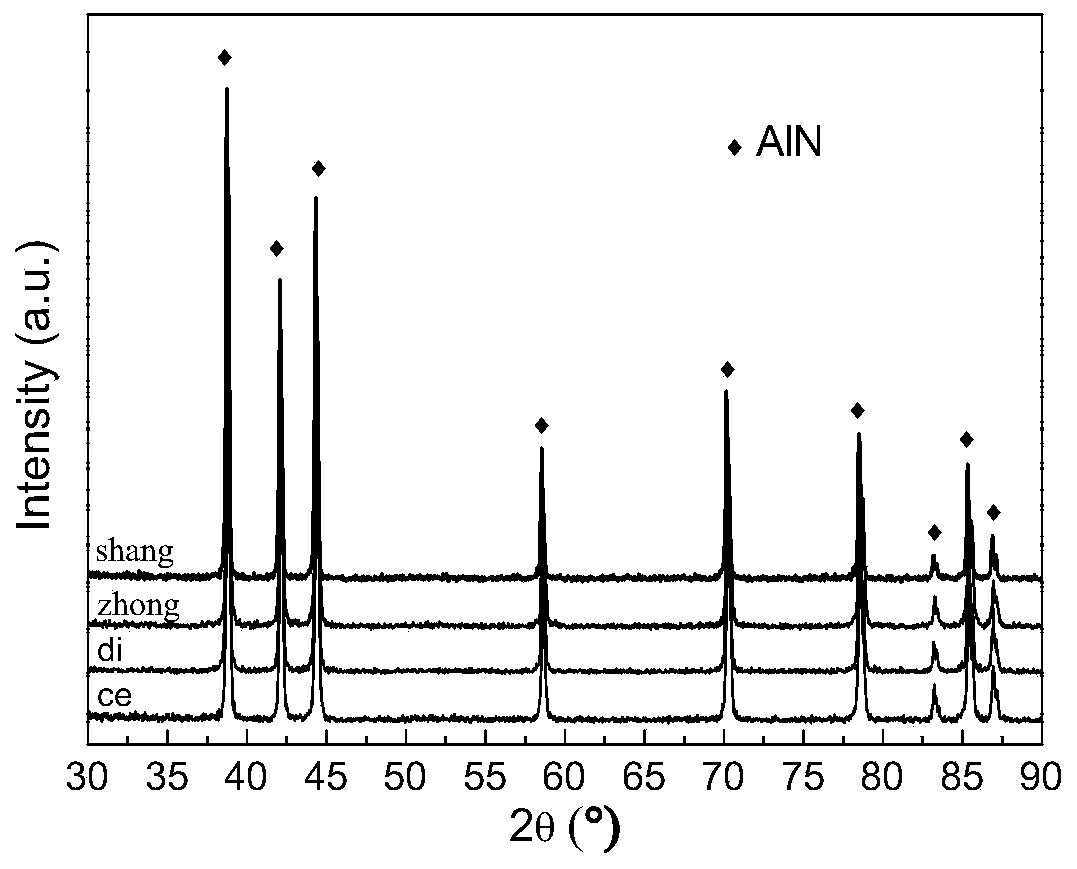

[0059] Embodiment 2 is according to the method for embodiment 1, and difference is that the lower limit of pressure in the furnace is made as 2.0kPa, and the upper limit pressure is made as 4kPa, and the cycle period is 4.4min; Step 3. heating rate is 5 ℃ / min. The XRD results of the synthesized powders located at different positions of the powder layer (upper surface, middle part, lower surface and side surface) are shown in Figure 6 , are pure phase AlN; the oxygen content of the powder is 1.02%; Figure 7 (a), the particle morphology after ball milling is shown in Figure 7 (b); the particle size distribution of AlN ceramic powder after ball milling is shown in Figure 8 , with an average particle size of about 1 μm.

Embodiment 3

[0061] Example 3 According to the method of Example 1, the difference is that step ③ synthesis temperature is 1650°C. The XRD results of the powders synthesized at different positions of the powder layer (upper surface, middle part, lower surface and side surface) are shown in Figure 9 , indicating that the phase composition of the powder prepared by this method is pure phase AlN; the oxygen content of the powder is 0.92%; the crystal grains of the synthesized AlN ceramic powder are small, and the particle morphology Figure 10 (a), the particles of the powder after ball milling are fine, and the appearance can be seen in Figure 10 (b); the particle size distribution of AlN ceramic powder after ball milling at 210rpm is shown in Figure 11 , the average particle size is about 0.9 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com