Preparation methods and applications of multistage hollow CoFe2O4 material and CoFe2O4/C composite

A composite material, cofe2o4 technology, which is applied to the preparation and application fields of multi-level hollow CoFe2O4 materials and CoFe2O4/C composite materials, can solve the problem of not containing secondary nanostructures and the like, and achieves the effects of simple process, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment prepares CoFe 2 o 4The process includes the following steps:

[0029] (1) Synthesis of precursor multilevel hollow Co-Fc-Hcps coordination polymer: Weigh 0.2000g (1.1mmol) 1,1'-ferrocenedicarboxylic acid and 0.2124g (1.1mmol) cobalt nitrate hexahydrate respectively Dissolve in 18mL DMF / H 2 O (the volume ratio of the two is 1:1), after stirring evenly, add the cobalt nitrate solution dropwise into the 1,1'-ferrocenedicarboxylic acid solution. The mixture was stirred evenly and then transferred to a 50mL reactor for 20h at 125°C, centrifuged and washed with DMF / H 2 O (volume ratio 1:1) was washed until clarified, and Co-Fc-Hcps coordination polymer was obtained after air-drying at 80°C for 15 hours;

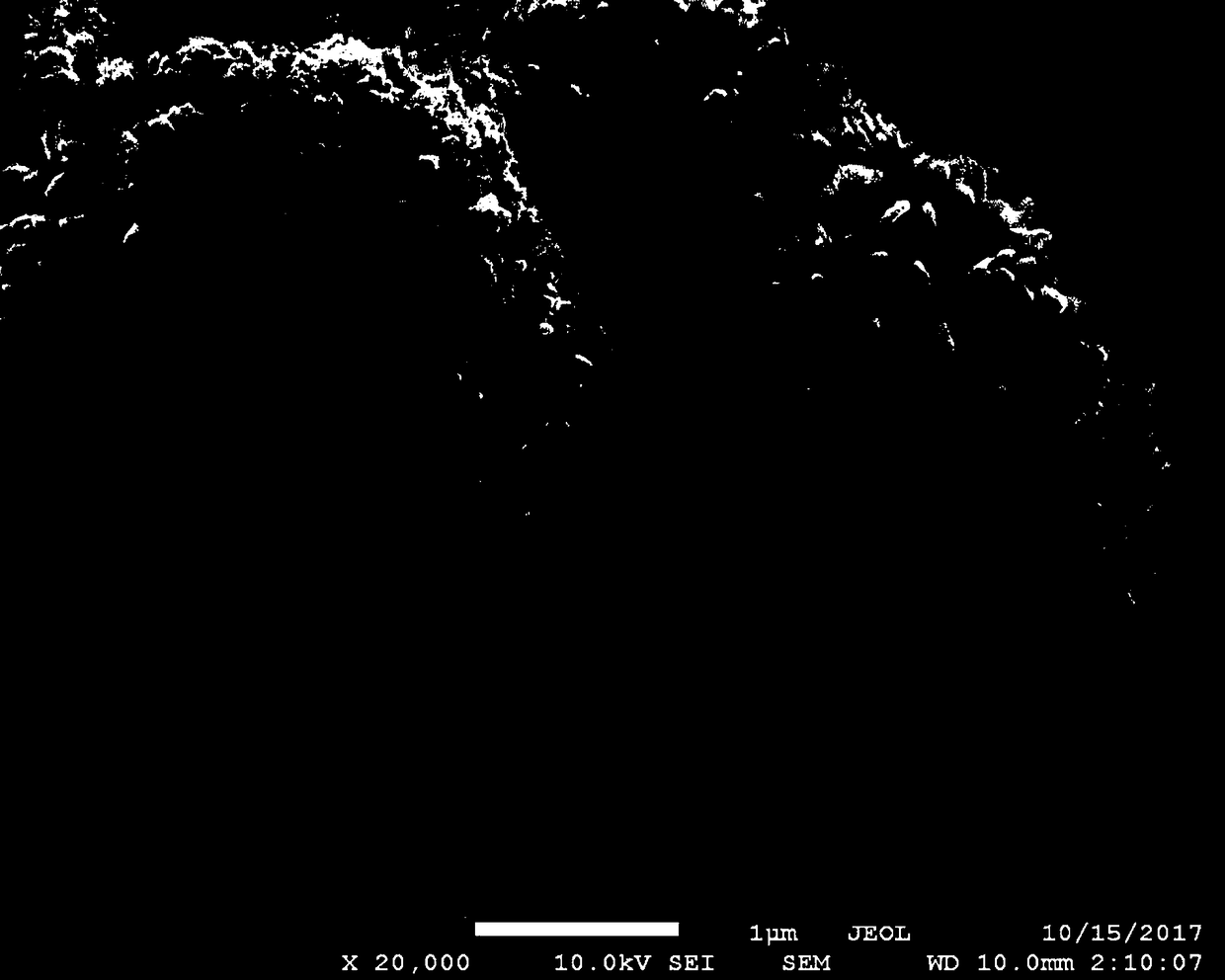

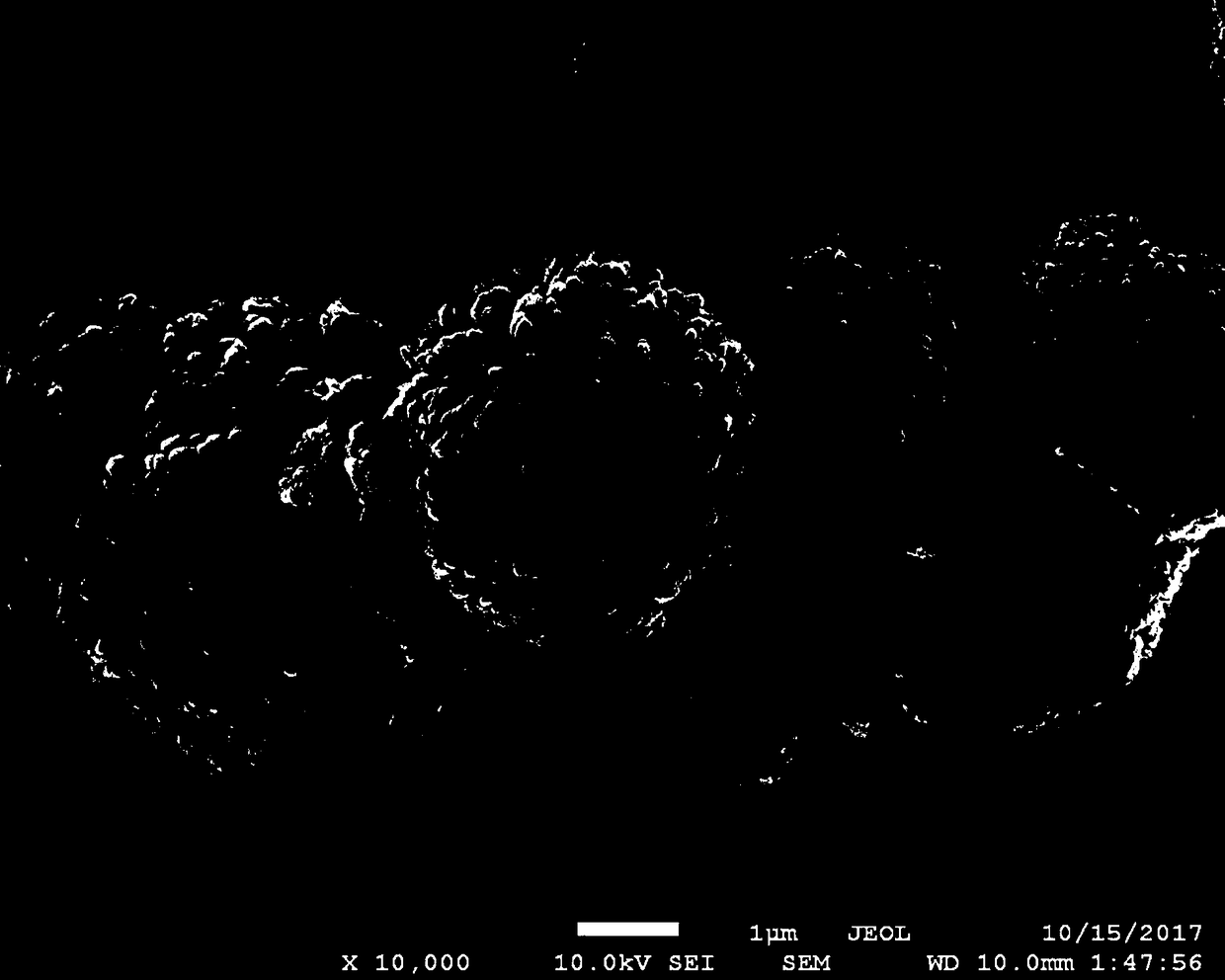

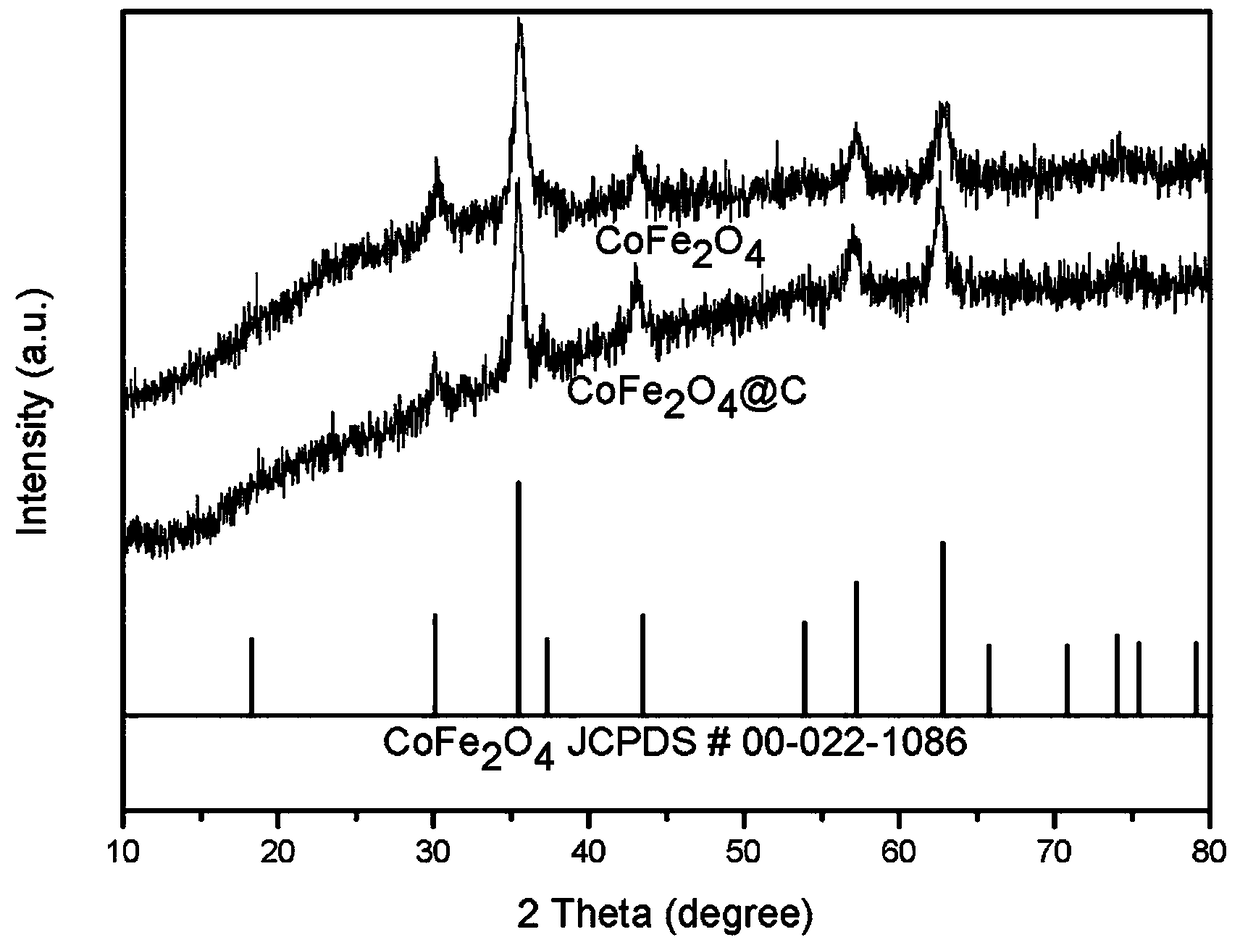

[0030] (2) The obtained Co-Fc-Hcps coordination polymer was calcined in a tube furnace at 350°C for 3h (3°C / min) to prepare CoFe 2 o 4 Material.

Embodiment 2

[0032] This embodiment prepares CoFe 2 o 4 The process includes the following steps:

[0033] (1) Synthesis of precursor multilevel hollow Co-Fc-Hcps coordination polymer: Weigh 0.5086g (1.8mmol) 1,1'-ferrocenedicarboxylic acid and 0.4326g (1.8mmol) cobalt nitrate hexahydrate respectively Dissolve in 18mL DMF / H 2 O (the volume ratio of the two is 1:1), after stirring evenly, add the cobalt nitrate solution dropwise into the 1,1'-ferrocenedicarboxylic acid solution. The mixture was stirred evenly and then transferred to a 50mL reactor at 125°C for 20h, centrifuged and washed with DMF / H 2 O (volume ratio 1:1) was washed until clarified, and Co-Fc-Hcps coordination polymer was obtained after air-drying at 80°C for 15 hours;

[0034] (2) The obtained Co-Fc-Hcps coordination polymer was calcined in a tube furnace at 450°C for 3h (3°C / min) to prepare CoFe 2 o 4 Material.

Embodiment 3

[0036] This embodiment prepares CoFe 2 o 4 The process includes the following steps:

[0037] (1) Synthesis of precursor multilevel hollow Co-Fc-Hcps coordination polymer: Weigh 0.5086g (1.8mmol) 1,1'-ferrocenedicarboxylic acid and 0.4326g (1.8mmol) cobalt chloride hexahydrate Dissolve in 18mL DMF respectively, stir evenly and add the cobalt chloride solution dropwise into the 1,1'-ferrocenedicarboxylic acid solution. The mixed solution was stirred evenly and then transferred to a 50mL reactor for reaction at 125°C for 12h, centrifuged and washed with DMF until clarified, and dried at 80°C for 15h to obtain the Co-Fc-Hcps coordination polymer;

[0038] (2) The obtained Co-Fc-Hcps coordination polymer was calcined in a tube furnace at 550°C for 3h (3°C / min) to prepare hollow CoFe 2 o 4 Material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com