Preparation method for cobalt-doped zinc oxide gas-sensitive material and application thereof

A technology of gas-sensing materials, zinc oxide, applied in the field of material chemistry and gas-sensing sensors, achieving the effects of good dispersion, high crystallinity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

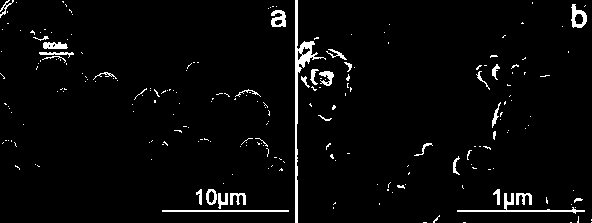

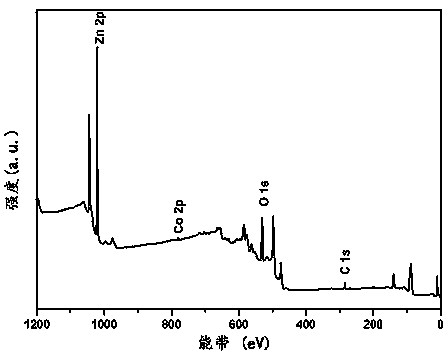

[0044] The preparation process of the nano-spherical cobalt-doped zinc oxide gas-sensitive material of the present invention is as follows:

[0045] (1) Dissolve 0.3g of polyvinylpyrrolidone (PVP) in 75ml of ethylene glycol (EG), and magnetically stir it to fully dissolve to form a transparent solution;

[0046] (2) then adding zinc acetate dihydrate to it, so that the concentration of zinc acetate is 0.09mol / l, magnetic stirring makes it fully dissolved to form a transparent solution;

[0047] (3) Add cobalt nitrate hexahydrate again, and now the mol ratio of cobalt nitrate hexahydrate and zinc acetate is 0.233, and magnetic stirring makes it fully dissolve to form a transparent red solution;

[0048] (4) Then the mixed solution was subjected to microwave treatment for 15 minutes at 500w microwave power, and 15 minutes for ultrasonic treatment at 360w ultrasonic power;

[0049] (5) Take an appropriate amount of reaction solution and place it in the reactor, so that the volum...

Embodiment 2

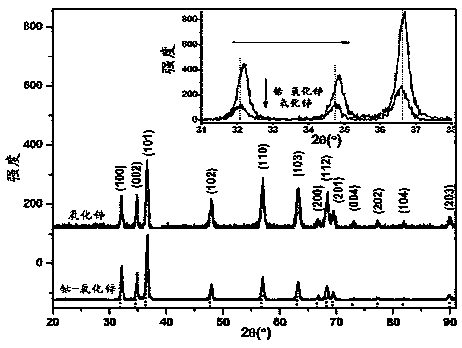

[0053] The preparation process of zinc oxide gas-sensing materials doped with different proportions of cobalt is as follows:

[0054] (1) A certain amount of polyvinylpyrrolidone (PVP) is dissolved in 75ml of ethylene glycol (EG), and magnetically stirred to fully dissolve it to form a transparent solution;

[0055] (2) then adding zinc acetate dihydrate to it, so that the concentration of zinc acetate is 0.09mol / l, magnetic stirring makes it fully dissolved to form a transparent solution;

[0056] (3) Add cobalt nitrate hexahydrate again, the mol ratios of cobalt nitrate hexahydrate and zinc acetate are respectively: 0.1, 0.075, 0.05 and 0.025, magnetic stirring makes it fully dissolve to form a transparent red solution;

[0057] (4) Then the mixed solution was subjected to microwave treatment for 15 minutes at a microwave power of 500w, and ultrasonic treatment for 15 minutes at an ultrasonic power of 360w;

[0058] (5) Take an appropriate amount of reaction solution and pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com