Composite insulator and preparation method thereof

A technology of composite insulators and insulators, applied in organic insulators, suspension/strain insulators, plastic/resin/wax insulators, etc. The effect of excellent toughening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] One embodiment of the preparation method of the composite insulator of the present invention includes:

[0043] S1: adding nanoparticles and nanoparticle modifiers to the resin matrix and then pre-mixing to form a resin mother liquor;

[0044] Specifically, the resin matrix may be epoxy resin, unsaturated resin, polyurethane or phenolic resin.

[0045] The nanoparticles can be selected from one or more of titanium dioxide, carbon black, silicon carbide, silicon nitride, aluminum oxide, carbon nanotubes, graphene, fullerene and fumed silicon dioxide.

[0046] The nano particle modifier is a mixture of one or more of silane coupling agent, titanate coupling agent, aluminate coupling agent, double metal coupling agent, phosphate ester coupling agent and chromium complex.

[0047] In a specific embodiment, this step can be selected as:

[0048] S101: After adding the nanoparticles and the nanoparticle modifier into the resin matrix, perform pre-mixing in a mixing device f...

Embodiment 1

[0063] Composite insulators include insulators. The insulators are formed by winding resin glue and fiber reinforcement. The resin glue is epoxy resin glue, and the fiber reinforcement is glass fiber yarn. Among the raw materials for the preparation of epoxy resin glue: resin matrix It is an epoxy resin, the nanoparticles are fumed silica, and the nanoparticle modifier is a silane coupling agent.

[0064] The mass ratio of raw materials for the preparation of epoxy resin glue is: 100 parts of epoxy resin, 5 parts of fumed silica, 1.5 parts of silane coupling agent, and 80 parts of curing agent.

[0065] The preparation method of the above composite insulator includes:

[0066] Step 1: Add 5phr fumed silica and 1.5phr silane coupling agent to 100phr epoxy resin, and pre-mix for 45min in the equipment with main propeller speed of 300rpm and high-speed propeller speed of 2000rpm to obtain stable dispersion of gas phase two Silica epoxy resin master solution.

[0067] Step 2: Ad...

Embodiment 2 and Embodiment 3

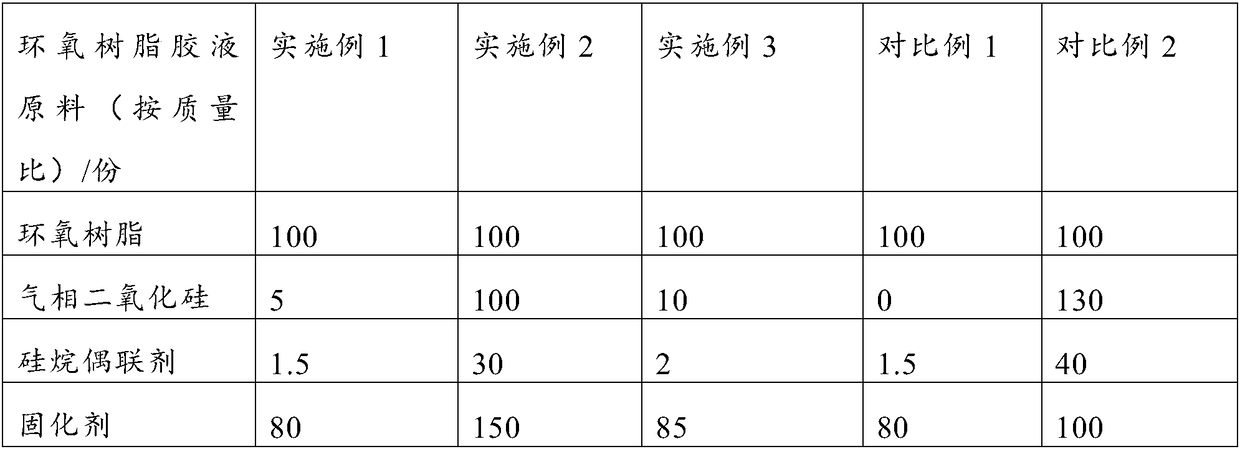

[0071] Implementation 2 and Example 3, compared with Example 1, the preparation method adopted is similar, the fiber reinforcements are all glass fiber yarns, the difference is that the mass ratio of each raw material in the epoxy resin glue is different, in order to further illustrate each raw material The influence of the mass ratio of the composite insulator on the performance of the insulator, and 2 other comparative examples are cited, and the preparation method of the comparative examples is also similar to that of Example 1.

[0072] Please refer to Table 1 and Table 2 for details.

[0073] Table 1 is the raw material mass ratio of epoxy resin glue solution in embodiment 1-embodiment 3, comparative example 1-comparative example 2

[0074]

[0075] Table 2 shows the flexural strength of the insulators in Example 1-Example 3, Comparative Example 1-Comparative Example 2.

[0076] project

Example 1

Example 2

Example 3

Comparative example 1

C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com