Durable epoxy resin joint filling material and preparation method thereof

A technology of epoxy resin and caulking material, applied in the direction of epoxy resin glue, novolac epoxy resin adhesive, adhesive type, etc. Good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

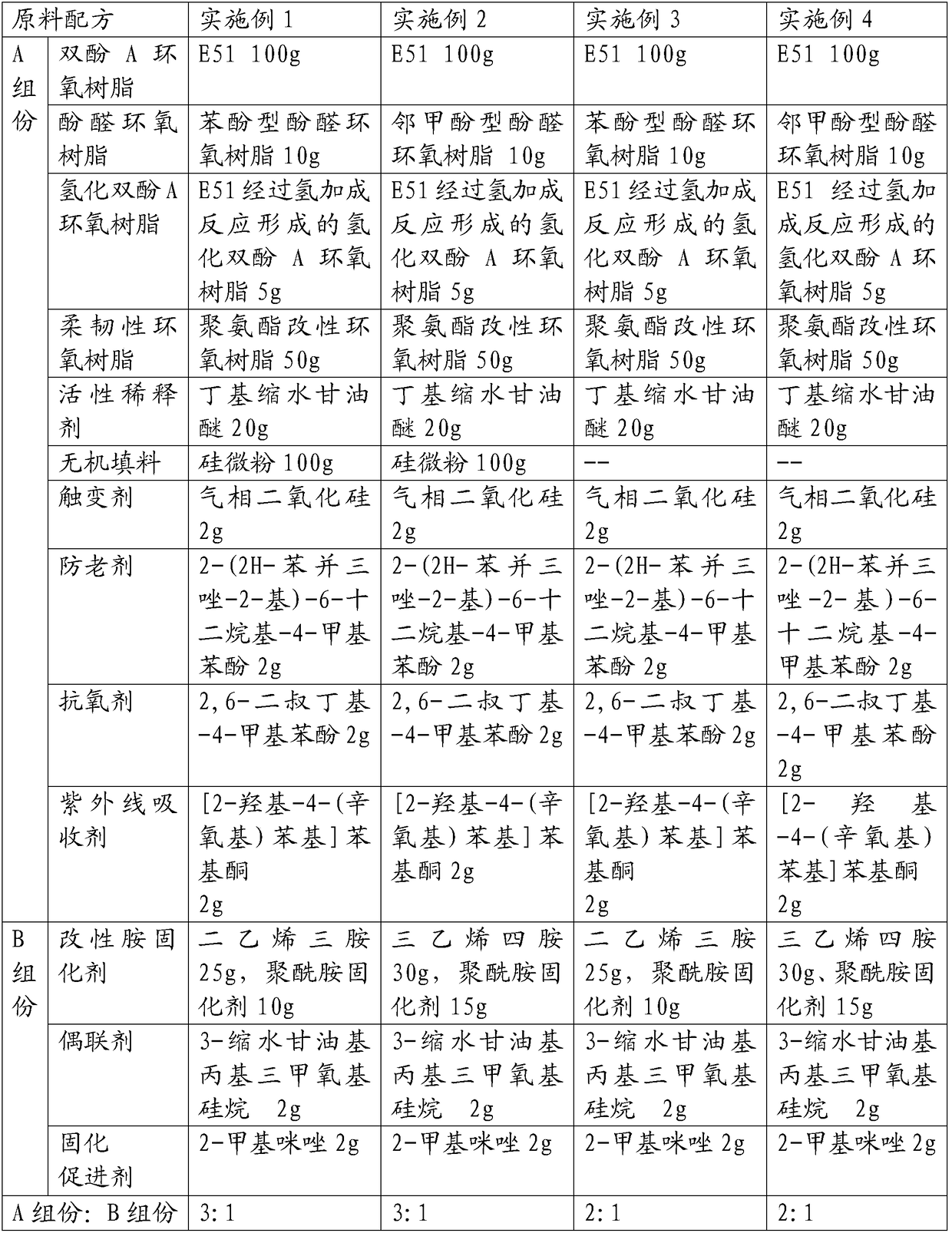

[0043] This embodiment provides a durable epoxy resin caulking material and its preparation method:

[0044] The raw material formula of this durable type epoxy resin caulking material is shown in Table 1;

[0045] The preparation method of the durable epoxy resin caulking material comprises the following steps:

[0046] Take 100g of bisphenol A epoxy resin E51, 10g of phenol novolac epoxy resin, 5g of hydrogenated bisphenol A epoxy resin, 50g of polyurethane modified epoxy resin, and 20g of butyl glycidyl ether. After mixing evenly, add thixotropic 2g anti-aging agent, 2g anti-oxidant, 2g ultraviolet absorber, 100g micro-silica powder, and mix well to obtain component A;

[0047] Take 25g of diethylenetriamine, 10g of polyamide curing agent, 2g of coupling agent, and 2g of 2-methylimidazole, and mix them uniformly to obtain component B.

[0048] Mix components A and B according to the ratio of parts by mass of 3:1 and then use it for caulking.

Embodiment 2

[0050] This embodiment provides a durable epoxy resin caulking material and its preparation method:

[0051] The raw material formula of this durable type epoxy resin caulking material is shown in Table 1;

[0052] The preparation method of the durable epoxy resin caulking material comprises the following steps:

[0053] Take bisphenol A epoxy resin E51 100g, o-cresol novolac epoxy resin 10g, hydrogenated bisphenol A epoxy resin 5g, polyurethane modified epoxy resin 50g, butyl glycidyl ether 20g, mix well and then add Thixotropic agent 2g, anti-aging agent 2g, antioxidant 2g, ultraviolet absorber 2g, silicon micropowder 100g, mix well to obtain component A;

[0054] Take 30g of triethylenetetramine, 15g of polyamide curing agent, 2g of coupling agent, and 2g of 2-methylimidazole, and mix them uniformly to obtain component B.

[0055] Mix components A and B according to the ratio of parts by mass of 3:1 and then use it for caulking.

Embodiment 3

[0057] This embodiment provides a durable epoxy resin caulking material and its preparation method:

[0058] The raw material formula of this durable type epoxy resin caulking material is shown in Table 1;

[0059] The preparation method of the durable epoxy resin caulking material comprises the following steps:

[0060] Get 100g of bisphenol A epoxy resin E51, 10g of phenol novolac epoxy resin, 5g of hydrogenated bisphenol A epoxy resin, 50g of polyurethane modified epoxy resin, and 20g of butyl glycidyl ether, mix well, then add touch 2g of variable agent, 2g of anti-aging agent, 2g of antioxidant, 2g of ultraviolet absorber, and mix evenly to obtain component A;

[0061] Take 25g of diethylenetriamine, 10g of polyamide curing agent, 2g of coupling agent, and 2g of 2-methylimidazole, and mix them uniformly to obtain component B.

[0062] Mix components A and B evenly in a ratio of 2:1 in parts by mass and then use it for caulking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com