Method for preparing ammonium-free plating assistant agent by recycling and utilizing low-zinc-contained acid wastewater

A technology of acid wastewater and recycling, applied in chemical instruments and methods, metallurgical wastewater treatment, oxidized water/sewage treatment, etc., can solve zinc content loss, secondary pollution of secondary hazardous waste iron sludge, and difficulty in adjusting pH value Control and other issues to achieve the effect of high efficiency and selectivity, high selectivity, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

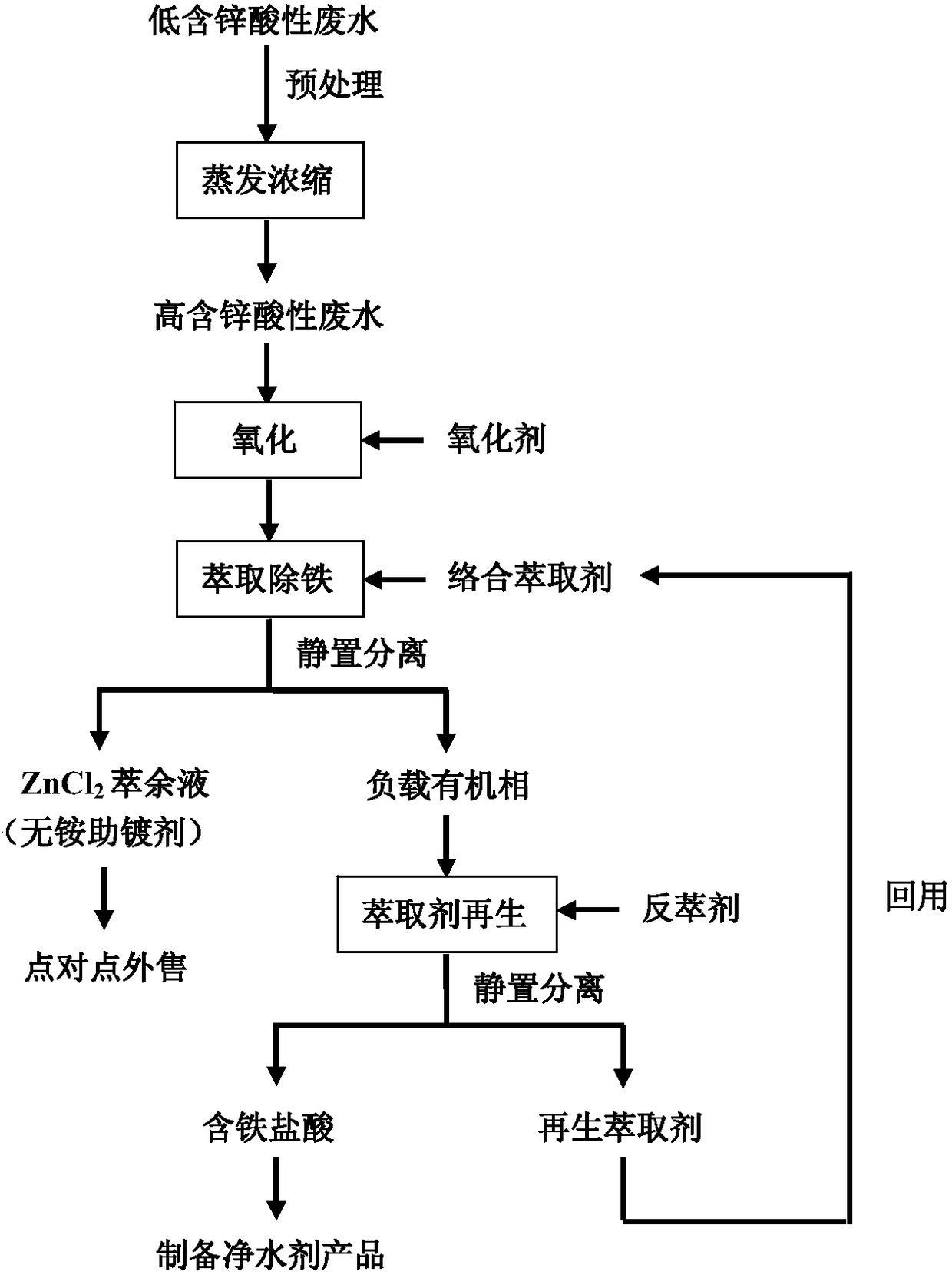

[0033] Such as figure 1 Shown a kind of resource recycling and utilization of low zinc-containing acidic wastewater to prepare the method for ammonium-free plating flux, comprising the following steps:

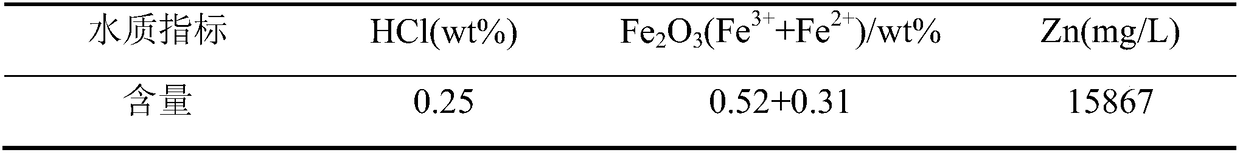

[0034] (1), concentrated, the low zinc-containing acidic wastewater described in Table 1 is pumped into the concentration equipment for pretreatment, stirred and evaporated and concentrated 10 times, to obtain high zinc-containing acidic wastewater;

[0035] (2), oxidize, add sodium chlorate in the highly zinc-containing acidic waste water after concentrated pretreatment in step (1), normal temperature stirring reaction 10min, a small amount of divalent iron in the waste water is all oxidized into ferric iron, chloric acid The mass ratio of sodium to high zinc-containing acidic wastewater is 0.75:100;

[0036] (3), extract and remove iron, add complexing extractant to the high zinc-containing acidic wastewater after oxidation in step (2) and carry out multistage continuous fo...

Embodiment 2

[0039] Such as figure 1 Shown a kind of resource recycling and utilization of low zinc-containing acidic wastewater to prepare the method for ammonium-free plating flux, comprising the following steps:

[0040] (1), concentrated, the low zinc-containing acidic wastewater described in Table 1 is pumped into the concentration equipment for pretreatment, stirred and evaporated and concentrated 10 times, to obtain high zinc-containing acidic wastewater;

[0041] (2), oxidize, add sodium chlorate in the highly zinc-containing acidic waste water after concentrated pretreatment in step (1), normal temperature stirring reaction 10min, a small amount of divalent iron in the waste water is all oxidized into ferric iron, chloric acid The mass ratio of sodium to high zinc-containing acidic wastewater is 0.75:100;

[0042] (3), extract and remove iron, add complexing extractant to the high zinc-containing acidic wastewater after oxidation in step (2) and carry out multistage continuous fo...

Embodiment 3

[0045] (1), concentration, the low zinc-containing acidic wastewater described in Table 1 is pumped into the concentration equipment for pretreatment, stirring and evaporating and concentrating 15 times, to obtain high zinc-containing acidic wastewater;

[0046] (2), oxidation, add sodium chlorate in the highly zinc-containing acidic waste water after concentrated pretreatment in step (1), normal temperature stirring reaction 15min, a small amount of divalent iron in the waste water is all oxidized into ferric iron, chloric acid The mass ratio of sodium to high zinc-containing acidic wastewater is 0.75:100;

[0047] (3), extract and remove iron, add complexing extractant to the high zinc-containing acidic wastewater after oxidation in step (2) and carry out multistage continuous forward extraction, the forward extraction volume ratio of complexing extractant and high zinc-containing acidic wastewater 5:1, stirred and reacted for 15 minutes, extracted the ferric iron into the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com