Carbon nanotube-loaded carbon paper and its preparation method and application

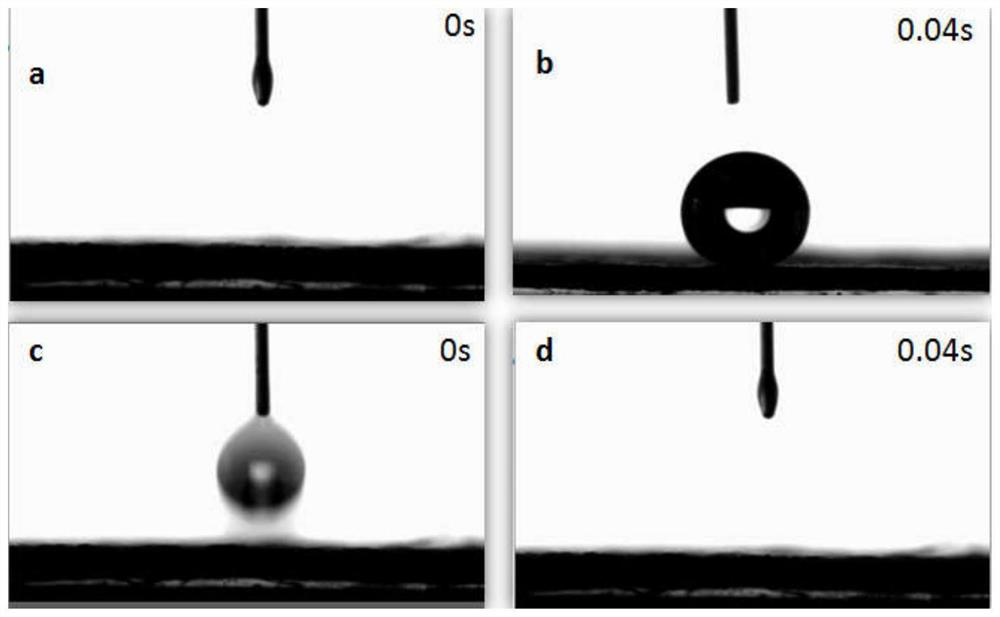

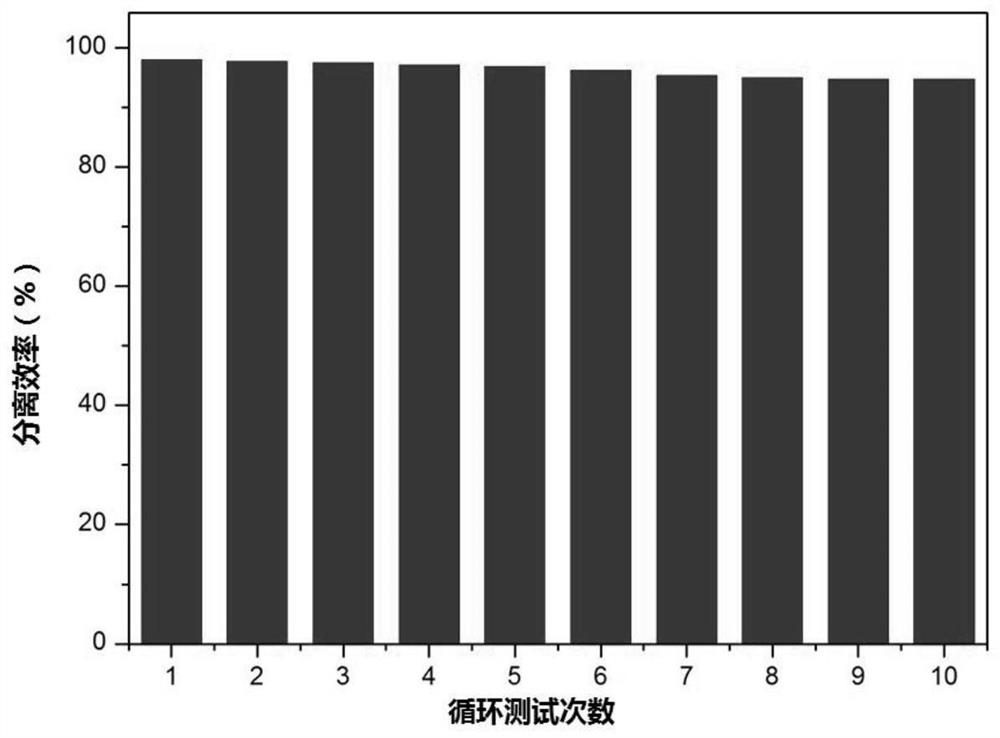

A technology of carbon nanotubes and carbon paper, which is applied in the field of carbon nanotube-loaded carbon paper and its preparation, can solve the problems of low separation efficiency, poor selectivity, poor cycle stability, etc., achieve high-efficiency separation, improve the firmness of the load, The effect of high-precision separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention also provides a preparation method of the above-mentioned carbon nanotube-loaded carbon paper, the method comprising:

[0050] 1) forming a metal catalyst layer on the carbon paper fiber surface of the carbon paper substrate;

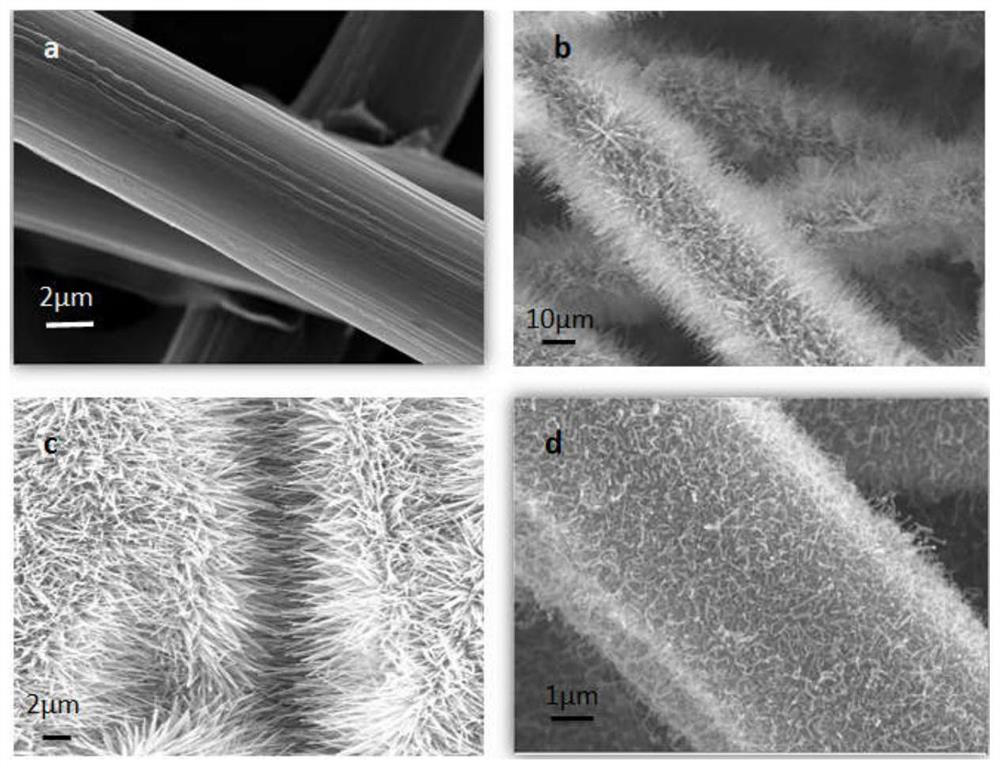

[0051] 2) in-situ formation of carbon nanotubes on the carbon paper fibers of the carbon paper substrate by vapor deposition;

[0052] 3) The product obtained in step 2) is covered with a hydrophobic polymer modification layer, and the hydrophobic polymer is selected from one or more of polyvinylpyrrolidone, polydimethylsiloxane and polytetrafluoroethylene.

[0053] According to the present invention, in step 1), the metal catalyst layer is not particularly limited, and may be one or more of existing cobalt-containing hydroxides used for synthesizing carbon nanotubes. As a method of forming the metal catalyst layer, it is preferably formed by hydrothermally reacting carbon paper with a water-soluble metal salt, urea, and am...

Embodiment 1

[0075] (1) Cut the carbon paper into a rectangle of 2cm×4cm (the weight is 6.4g, the same below), and treat both sides of the carbon paper in a 200W plasma cleaning machine for 5min.

[0076] (2) 0.291g cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O), 0.6g urea (CO(NH 2 ) 2 ), 0.093g ammonium fluoride (NH 4 F) Mix it with 30mL deionized water and add it into a 50mL reaction kettle to form a uniform solution. Sonicate until completely dissolved to form a uniform pink solution. Put the treated carbon paper into the reaction kettle and ultrasonicate for 30 minutes, so that the mixed solution completely soaks the carbon paper.

[0077] (3) The reaction kettle was placed in an oven at 120° to react for 24 hours. After the reaction, the reaction kettle was taken out to cool down naturally, and the carbon paper with the cobalt catalyst was taken out. It can be observed that there are pink deposits on the upper and lower sides of the carbon paper, wherein the upper layer is phy...

Embodiment 2

[0084] (1) Cut the carbon paper into a rectangle of 2cm×4cm, and treat both sides of the carbon paper for 5 minutes in a plasma cleaning machine with a power of 200W.

[0085] (2) Mix 0.582g of cobalt nitrate hexahydrate, 1.200g of urea, 0.233g of ammonium fluoride and 30mL of deionized water into a 50mL reactor to form a homogeneous solution, and ultrasonicate until completely dissolved to form a uniform pink solution. Put the treated carbon paper into the reaction kettle and ultrasonicate for 30 minutes, so that the mixed solution completely soaks the carbon paper.

[0086] (3) The reaction kettle was placed in an oven at 120° for hydrothermal reaction for 12 hours. After the reaction, the reaction kettle was taken out to cool down naturally, and the carbon paper with the cobalt catalyst was taken out, the surface of the carbon paper was cleaned with deionized water, and then placed in a vacuum drying oven at 60°C for 30 min.

[0087] (4) Place the carbon paper obtained in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com