Zeolite molecular sieve adsorbent preparation method and zeolite molecular sieve adsorbent

A zeolite molecular sieve and adsorbent technology, which is applied in the field of zeolite molecular sieve adsorbent preparation, can solve the problems of complicated zeolite molecular sieve process, unfavorable popularization and application of zeolite molecular sieve, etc., and achieves the effect of simplifying the preparation process and reducing the manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

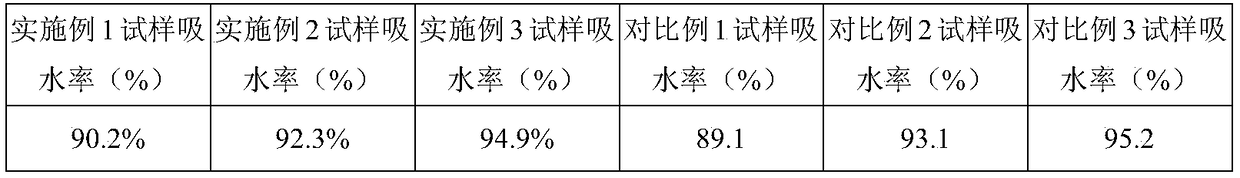

Examples

preparation example Construction

[0026] In order to solve the problems in the prior art, an embodiment of the present invention provides a method for preparing a zeolite molecular sieve adsorbent, the method comprising:

[0027] (1), weighing raw materials, including: weighing 70-110 parts by weight of aluminum alkoxide, 50-90 parts by weight of sodium silicate, 15-25 parts by weight of nano-titanium dioxide, 5-15 parts by weight of silylated polymer thing, the binder of 3-8 parts by weight, the lubricant of 3-8 parts by weight;

[0028] Specifically, the purity of the aluminum alkoxide is not less than 96%; the silylated polymer can be a silylated polymer with a molecular weight of 40,000-80,000; the particle diameter of the nano-titanium dioxide is 20-40nm, and the purity is not less than 91 %. The binder is polyoxyethylene with a particle size of 15-30 mesh and a molecular weight of 800,000-1,200,000 produced by Jilin Global Fine Chemical Co., Ltd. The lubricant is lactic acid with a purity of not less t...

Embodiment 1

[0040] (1), take raw material, comprise: take by weighing 70 kilograms, the aluminum alkoxide that purity is 96%, 90 kilograms, the sodium silicate that purity is 96%; 15 kilograms, particle diameter is 20nm, purity is 91% nano-titanium dioxide; 5 kg of silanized polymer with a molecular weight of 40,000; 8 kg of polyethylene oxide with a particle size of 15 mesh and a molecular weight of 800,000 produced by Jilin Global Fine Chemical Co., Ltd.; 8 kg of, Lactic acid with a purity of 80%;

[0041] (2), the raw material that weighs is added in the reaction kettle, then add the deionized water whose total mass is 120% of the total mass of the raw material and the conductivity is 1 micro-Siemens / cm, stir with the rotating speed of 150r / min, According to the heating rate of 0.5 degrees Celsius / minute, the reactor was heated to 55 degrees Celsius and kept for 8 hours, and then the reactor was cooled to below 40 degrees Celsius according to the temperature reduction rate of 0.5 degre...

Embodiment 2

[0046] (1), take raw materials, comprise: take by weighing 90 kilograms, the aluminum alkoxide that purity is 97%, 70 kilograms, the sodium silicate that purity is 97%; 20 kilograms, particle diameter is 30nm, purity is 93% nano-titanium dioxide; 10 kg of silanized polymer with a molecular weight of 60,000; 5 kg of polyethylene oxide with a particle size of 20 mesh and a molecular weight of 1 million produced by Jilin Global Fine Chemical Co., Ltd.; 5 kg of, Lactic acid with a purity of 85%;

[0047](2), the raw material that weighs is added in the reaction kettle, then add the deionized water whose total mass is 150% of the total mass of the raw material and the conductivity is 1.2 micro-Siemens / cm, stir with the rotating speed of 200r / min, According to the heating rate of 0.7 degrees Celsius / minute, the reactor was heated to 57 degrees Celsius and kept for 10 hours, and then the reactor was cooled to below 40 degrees Celsius according to the heating rate of 0.7 degrees Celsi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com