Metal boride water-splitting catalyst, preparation method and application of catalyst in electro-catalytic water splitting

A metal boride and water splitting technology, applied in preparation, application of electrocatalytic water splitting, and high-efficiency metal boride water splitting catalyst field, can solve the limitation of large-scale production and application, reduce the overpotential of oxygen evolution reaction, and accelerate power Chemical reaction and other problems, to achieve the effect of promoting commercial application, saving catalyst cost, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

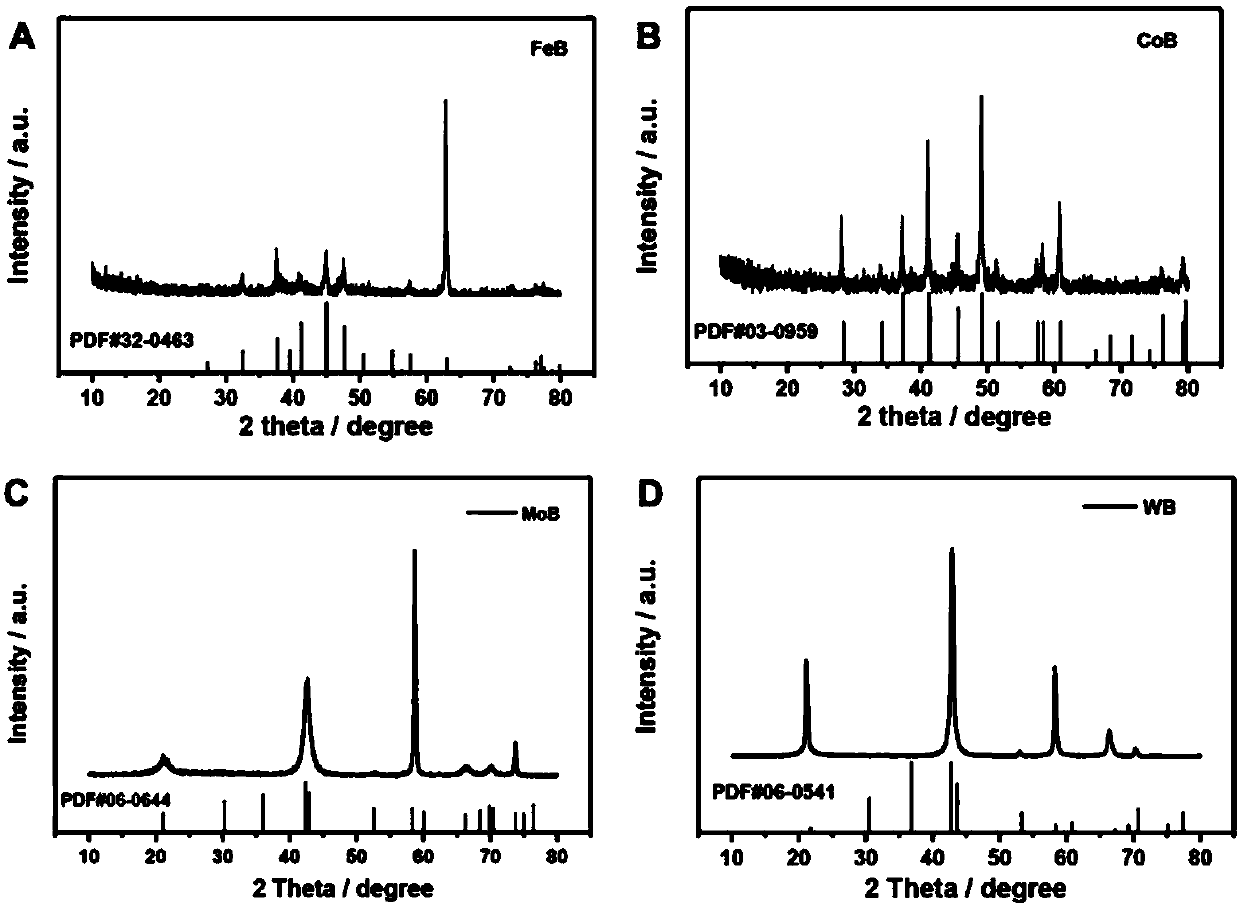

[0041] Experiment 1. Synthesis of metal boride water splitting catalyst with a molar ratio of metal to boron atom of 1:1 (MB)

[0042] (1) Weigh 8.1g (ie 0.75mol) of amorphous boron (B) and 0.9g (ie 0.0071mol) of potassium fluoroborate (KBF 4 ), fully grind and mix uniformly to obtain boronizing agent;

[0043] (2) Put 4 parts of the boronizing agent obtained in step (1) into 4 stainless steel tanks respectively, and then put 0.75mol of transition metals Fe, Co, Mo and W respectively, so that they are completely embedded in the boronizing agent middle;

[0044] (3) completely seal the stainless steel tank in step (2) with refractory mud, then fully dry under 100 ℃;

[0045] (4) The temperature of the stainless steel tank dried in step (3) was raised to 800° C. and calcined for 2 hours to obtain a metal boride water splitting catalyst with a molar ratio of metal to boron atoms of 1:1 (MB).

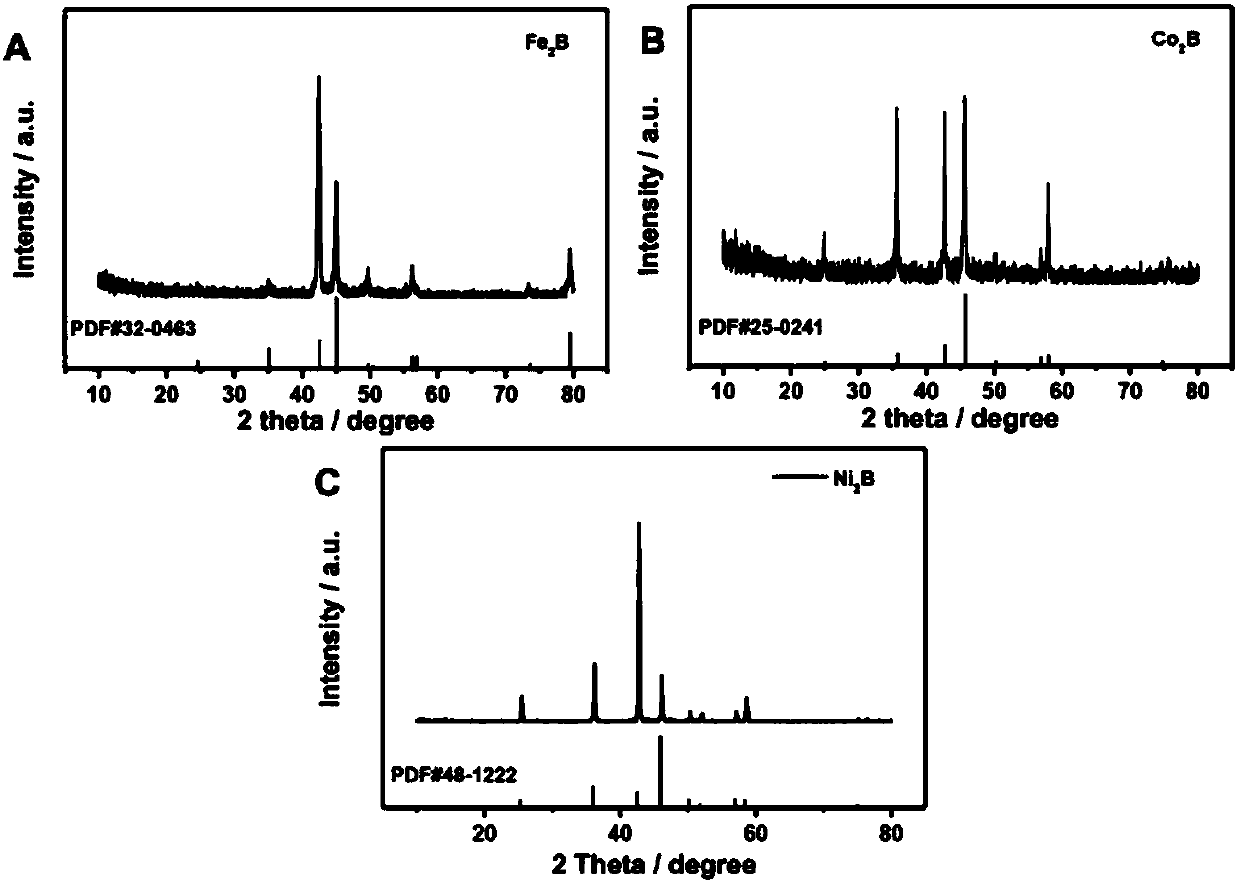

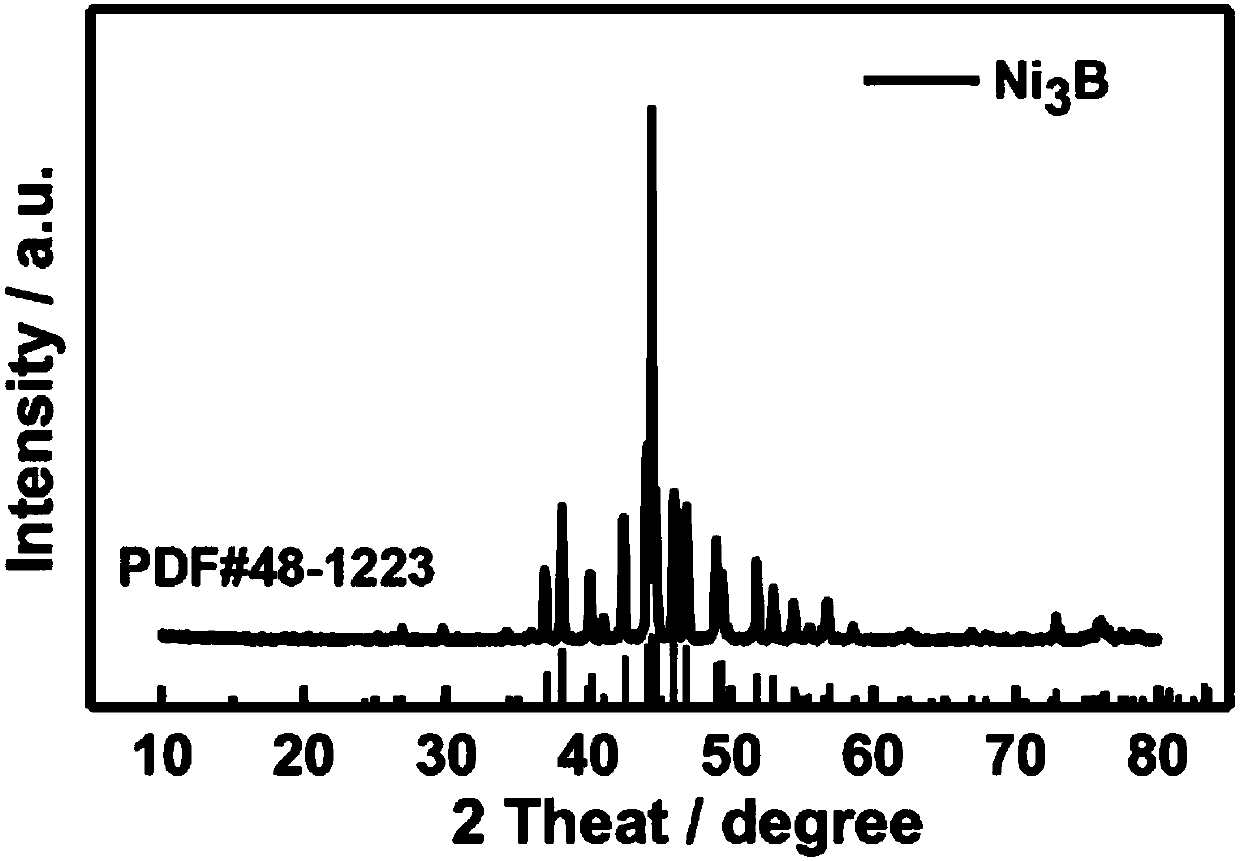

[0046] Experiment 2. The molar ratio of synthetic metal to boron atom is 2:1 (M 2 B...

Embodiment 2

[0063] Same as embodiment 1, just change the boriding medium into B 4 C, under the condition of 1M KOH, the electrocatalytic performance of the obtained sample:

[0064] Metal borides (MB) with a molar ratio of metal to boron atoms of 1:1: CoB, FeB, MoB, and WB at overpotentials of 361mV, 373mV, 431mV, and 459mV respectively, reaching a current density of 10mA cm -2 .

[0065] Metal borides (MB) with a 2:1 molar ratio of metal to boron atoms: Ni 2 B. Co. 2 B. Fe 2 B respectively at the overpotential of 345mV, 376mV, 409mV, the current density is 10mA cm -2 .

[0066] Metal borides (MB) with a 3:1 molar ratio of metal to boron atoms: Ni 3 B at an overpotential of 313mV, reaching a current density of 10mA cm -2 .

Embodiment 3

[0068] Same as embodiment 1, just change the boriding medium into NaB 4 o 7 , under the condition of 1M KOH, the electrocatalytic performance of the obtained sample:

[0069] Metal borides (MB) with a molar ratio of metal to boron atoms of 1:1: CoB, FeB, MoB, and WB at overpotentials of 364mV, 373mV, 429mV, and 463mV respectively, reaching a current density of 10mA cm -2 .

[0070] Metal borides (MB) with a 2:1 molar ratio of metal to boron atoms: Ni 2 B. Co. 2 B. Fe 2 B, when the overpotential is 348mV, 363mV, 403mV respectively, the current density is 10mA cm -2 .

[0071] Metal borides (MB) with a 3:1 molar ratio of metal to boron atoms: Ni 3 B at an overpotential of 312mV, reaching a current density of 10mA cm -2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com