Sludge deodorant and preparation method thereof

A deodorant and sludge technology, which is applied in the field of sludge deodorant and its preparation, can solve the problems of inconspicuous effect, the inability of microorganisms to achieve rapid film formation, and reduce the decomposition efficiency of microorganisms, so as to speed up the decomposition efficiency and avoid secondary pollution. Secondary pollution and medium pollution transfer, deodorizing effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

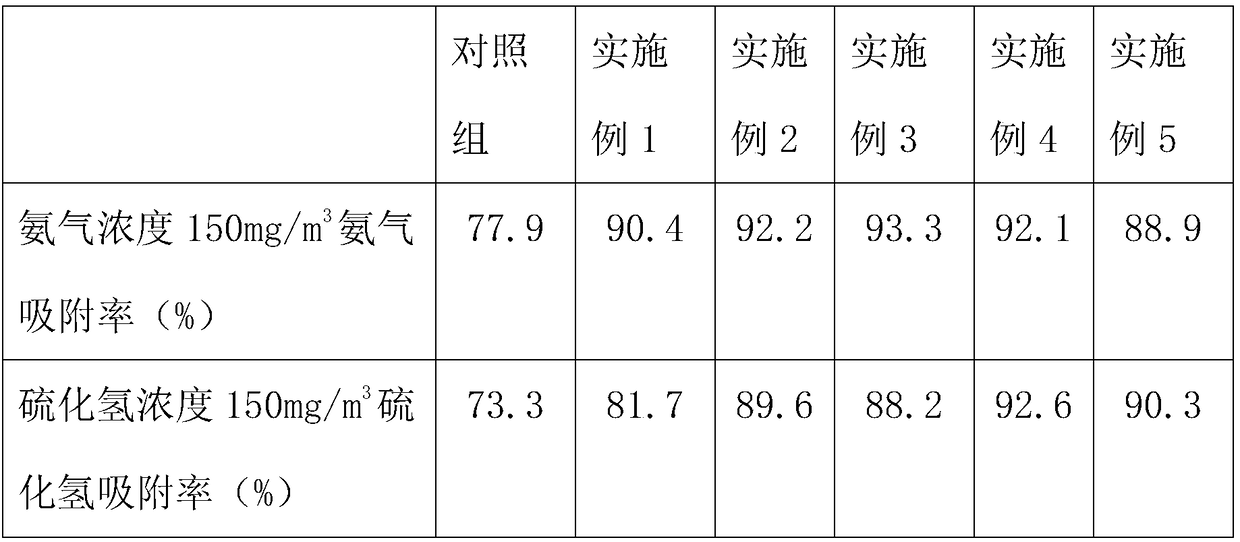

Examples

Embodiment 1

[0026] The present embodiment provides a sludge deodorant, comprising the following components in parts by weight: 35 parts of diatomaceous earth, 10 parts of tung oil, 5 parts of colloidal alumina, 20 parts of activated carbon, 5 parts of polypropylene diester, 15 parts of ferric chloride, 20 parts of fragrance, 5 parts of matrine, 5 parts of black poplar, 10 parts of black locust, 20 parts of accelerator, 2 parts of dispersant, 3 parts of titanium dioxide powder, 4 parts of zinc oxide powder.

[0027] The aromatic agent is tea polyphenols.

[0028] The accelerator is sodium permanganate.

[0029] The particle size of the zinc oxide powder, titanium dioxide powder and activated carbon is 300 μm.

[0030] The dispersant is zirconia with a particle size of 500 μm.

[0031] A preparation method of sludge deodorant, specifically comprising the steps of:

[0032] S1: Weigh matrine, black poplar, and black locust in parts by weight, and rinse with deionized water for 10 minutes,...

Embodiment 2

[0039] The present embodiment provides a sludge deodorant, comprising the following components in parts by weight: 40 parts of diatomaceous earth, 12 parts of tung oil, 6 parts of colloidal alumina, 22 parts of activated carbon, 6 parts of polypropylene diester, 16 parts of ferric chloride, 24 parts of fragrance, 6 parts of matrine, 7 parts of black poplar, 12 parts of black locust, 22 parts of accelerator, 2 parts of dispersant, 4 parts of titanium dioxide powder, and 5 parts of zinc oxide powder.

[0040] The aromatic agent is tea polyphenols and isoflavones, and the mixing ratio is 1:1.

[0041] The accelerator is sodium ferrate.

[0042] The particle size of the zinc oxide powder, titanium dioxide powder and activated carbon is 310 μm.

[0043] The dispersant is zirconia with a particle size of 520 μm.

[0044] A preparation method of sludge deodorant, specifically comprising the steps of:

[0045] S1: Weigh matrine, black poplar, and black locust in parts by weight, an...

Embodiment 3

[0052] The present embodiment provides a sludge deodorant, comprising the following components in parts by weight: 45 parts of diatomaceous earth, 12 parts of tung oil, 8 parts of colloidal alumina, 25 parts of activated carbon, 7 parts of polypropylene diester, 18 parts of ferric chloride, 26 parts of fragrance, 8 parts of matrine, 12 parts of black poplar, 13 parts of black locust, 26 parts of accelerator, 2 parts of dispersant, 3 parts of titanium dioxide powder, and 5 parts of zinc oxide powder.

[0053] The aromatics are flavonoids.

[0054] The accelerator is sodium perchlorate.

[0055] The particle size of the zinc oxide powder, titanium dioxide powder and activated carbon is 330 μm.

[0056] The dispersant is zirconia with a particle size of 550 μm.

[0057] A preparation method of sludge deodorant, specifically comprising the steps of:

[0058] S1: Weigh matrine, black poplar, and black locust in parts by weight, and wash them with deionized water for 15 minutes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com