Super high-strength, high-toughness and wear-resistant steel and preparation method thereof

A high-strength, high-toughness, wear-resistant steel technology, applied in the field of ultra-high-strength, high-toughness wear-resistant steel and its manufacturing, can solve the problems of poor welding performance, slow isothermal transformation speed, and difficult to achieve, and achieve weldability and forgeability. Good performance, wide range of applications, significant elongation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

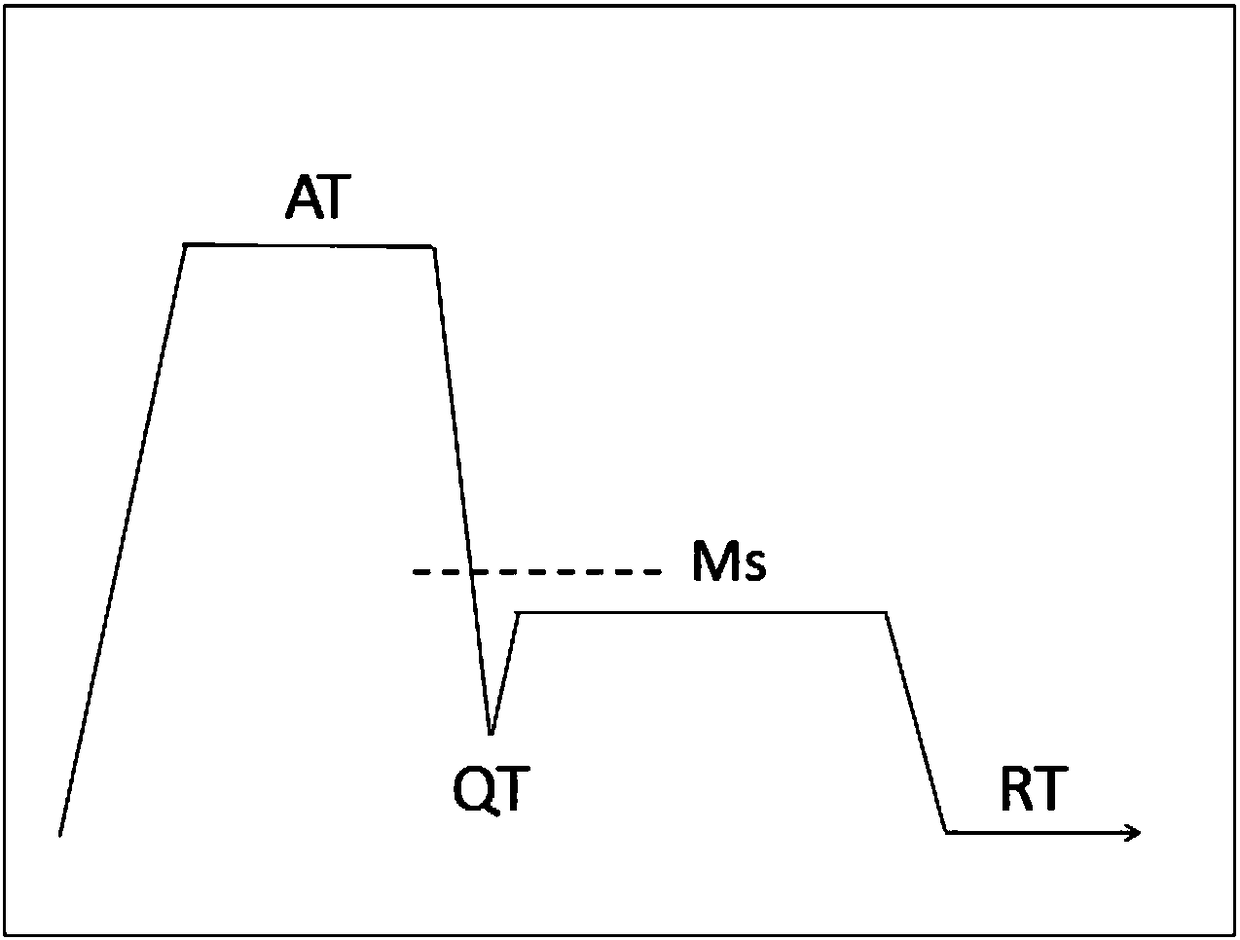

Method used

Image

Examples

Embodiment 1

[0026] Utilize the drilling rod technique of the present invention to produce to be: chemical composition is wt%: C 0.35%, Si 1.50%, Mn1.50%, Cr0.80%, Mo 0.20%, Re0.01%, S2 , hardness HRC55.

Embodiment 2

[0028] Utilize the technology of the advanced roadheader cutter rod produced by the present invention to be: chemical composition is wt%: C 0.45%, Si2.1%, Mn 1.95%, Cr 0.40%, Mo 0.20%, Re 0.02%, S2 , The elongation after breaking is 16.5%, and the hardness is HRC61.

Embodiment 3

[0030] Utilize the technology of the armored track shoe that the present invention produces is: chemical composition is wt%: C 0.40%, Si1.88%, Mn1.50%, Cr 0.40%, Mo 0.40%, Re 0.02%, S2 , The elongation after breaking is 17%, and the hardness is HRC56.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com