High temperature and severe cold resistant cable

A high temperature resistant and cable technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve problems that affect the safe operation of transmission lines, cable deicing jumps, phase short circuits, etc., to reduce ice disasters and improve safety and reliability , the effect of small bending radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

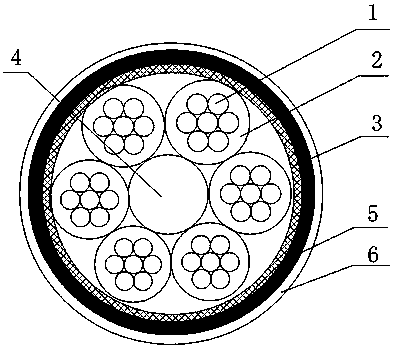

[0022] Such as figure 1 The high temperature and cold resistant cable shown includes a conductor 1, an insulating layer 2, and a braiding layer 3. The insulating layer 2 is covered on the conductor 1. The conductor 1 and the insulating layer 2 form an insulated core. The insulated core has 6 group; the cable also includes a filling core 4, the filling core 4 is located in the center of the cable, and the 6 sets of insulated cores are wrapped around it; the stranded pitch-to-diameter ratio of the insulated cores is 10-15. The material of the insulating layer 2 is a modified cross-linked ethylene-tetrafluoroethylene copolymer material. Using cross-linked ethylene-tetrafluoroethylene copolymer as the insulating layer, the cable is more resistant to high temperature and cold.

[0023] After the insulated wire core is cabled, it is wrapped around the cladding 5, which is a fire-resistant rubberized glass cloth tape. The braiding layer 3 is wound around the outer periphery of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com