Amorphous strontium titanate thin-film device and preparation method thereof

A thin-film device, strontium titanate technology, applied in the direction of electrical components, etc., can solve the problems of expensive raw materials, high temperature required for preparation, poor stability and easy fatigue, etc., and achieve the effect of wide application fields, large switching ratio and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

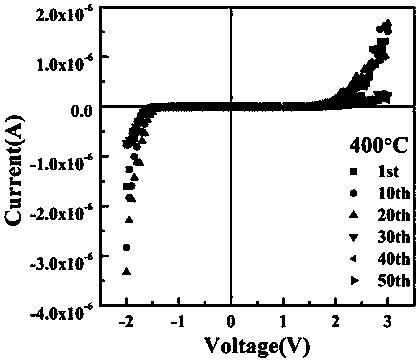

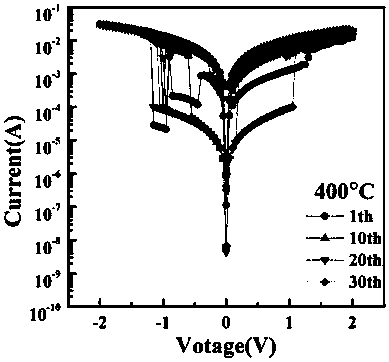

Examples

Embodiment 1

[0053] With strontium nitrate Sr(NO 3 ) 2 (99.5%) as raw material; ethylene glycol as solvent. Strontium nitrate Sr(NO 3 ) 2 (99.5%) was dissolved in ethylene glycol, and stirred at 50°C for 4 to 5 hours until fully dissolved to obtain a strontium nitrate solution.

[0054] Butyl phthalate Ti(OC 4 h 9 ) 4 (99%) as starting material; acetylacetone as solvent. According to the stoichiometric ratio and the molar ratio of strontium nitrate is 1:1 weighing, the butyl phthalate Ti(OC 4 h 9 ) 4 (99%) dissolved in acetylacetone, stirred at room temperature for 2 to 2.5 hours until fully dissolved to obtain butyl phthalate solution.

[0055] The butyl titanate solution was added dropwise to the strontium nitrate solution, stirred at a constant speed for 5 hours, and the concentration of the solution was adjusted to 0.25 mol / L with acetylacetone to obtain a strontium titanate solution.

[0056] SrTiO 3 The (STO) solution is spin-coated on the FTO conductive glass, spin-coate...

Embodiment 2

[0065] With strontium nitrate Sr(NO 3 ) 2 (99.5%) as raw material; ethylene glycol as solvent. Strontium nitrate Sr(NO 3 ) 2 (99.5%) was dissolved in ethylene glycol, and stirred at 50°C for 4.5 hours until fully dissolved to obtain strontium nitrate solution.

[0066] Butyl phthalate Ti(OC 4 h 9 ) 4 (99%) as starting material; acetylacetone as solvent. According to the stoichiometric ratio and the molar ratio of strontium nitrate is 1:1 weighing, the butyl phthalate Ti(OC 4 h 9 ) 4 (99%) was dissolved in acetylacetone, and stirred at room temperature for 2 hours until fully dissolved to obtain a butyl phthalate solution.

[0067] The butyl titanate solution was added dropwise to the strontium nitrate solution, stirred at a constant speed for 5 hours, and the concentration of the solution was adjusted to 0.25 mol / L with acetylacetone to obtain a strontium titanate solution.

[0068] SrTiO 3 The (STO) solution is spin-coated on the FTO conductive glass, spin-coated ...

Embodiment 3

[0074] With strontium nitrate Sr(NO 3 ) 2 (99.5%) as raw material; ethylene glycol as solvent. Strontium nitrate Sr(NO 3 ) 2 (99.5%) was dissolved in ethylene glycol, and stirred at 50°C for 5 hours until fully dissolved to obtain strontium nitrate solution.

[0075] Butyl phthalate Ti(OC 4 h 9 ) 4 (99%) as starting material; acetylacetone as solvent. According to the stoichiometric ratio and the molar ratio of strontium nitrate is 1:1 weighing, the butyl phthalate Ti(OC 4 h 9 ) 4 (99%) was dissolved in acetylacetone, and stirred at room temperature for 2 hours until fully dissolved to obtain a butyl phthalate solution.

[0076] The butyl titanate solution was added dropwise to the strontium nitrate solution, stirred at a constant speed for 5 hours, and the concentration of the solution was adjusted to 0.25 mol / L with acetylacetone to obtain a strontium titanate solution.

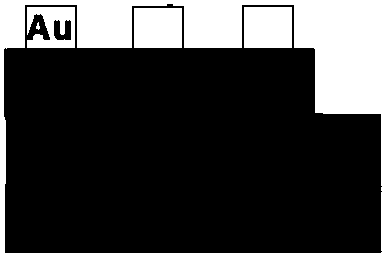

[0077] SrTiO 3 (STO) solution spin coating on SiO 2 / Si (silicon oxide / silicon wafer is a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com