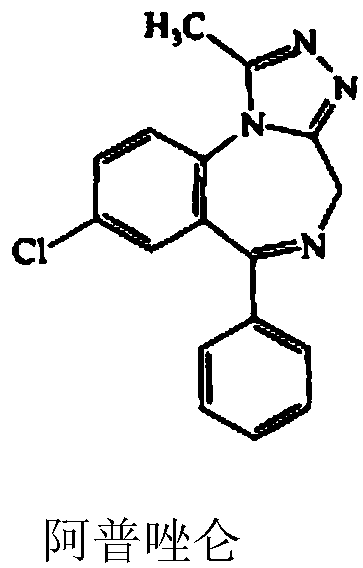

Preparation method of alprazolam intermediate

A technology of alprazolam and intermediates, which is applied in the field of preparation of alprazolam intermediates and achieves the effects of shortening reaction time, short reaction time and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

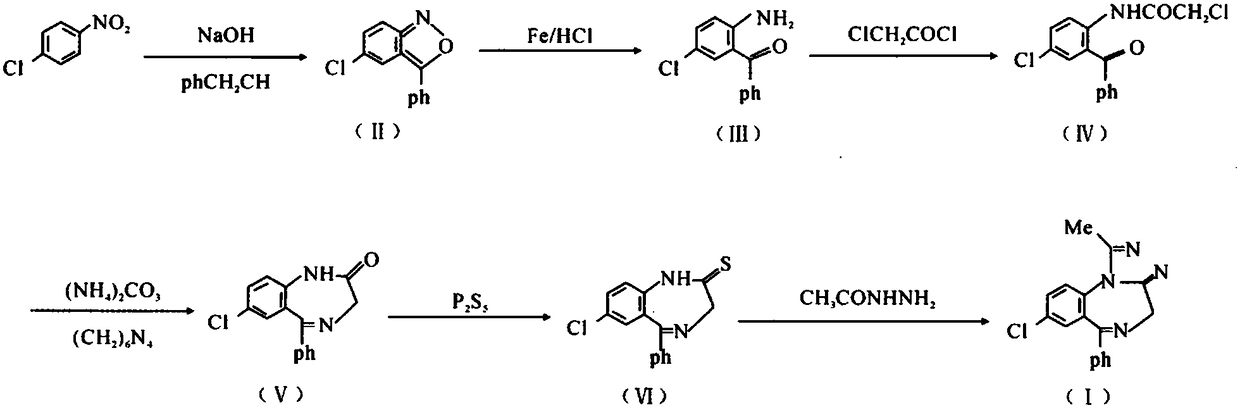

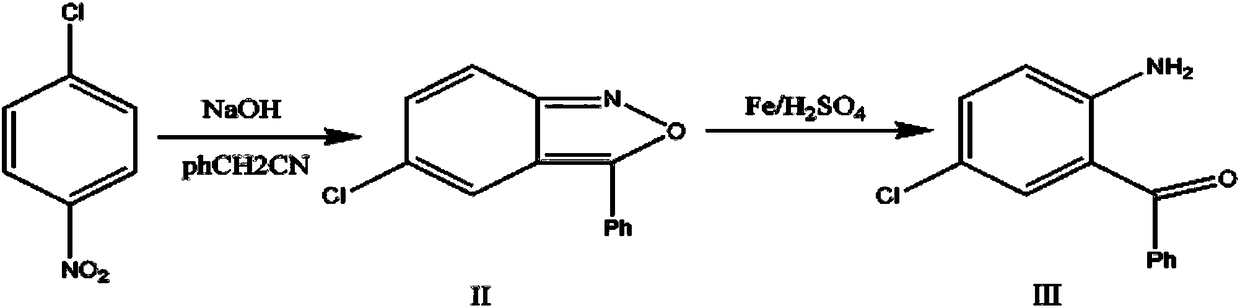

Method used

Image

Examples

Embodiment 1

[0030] (1) Put 25g of sodium hydroxide solid into 100ml of purified water, cool down to 30°C, add 12ml of methanol, add 10g of p-nitrochlorobenzene under stirring, react for 0.5h, add 7.4g of phenylacetonitrile dropwise, and dropwise complete in 15min . After the dropwise addition was completed, the temperature was raised to 40° C., and the reaction was carried out for 1.5 h. After the reaction was completed, the temperature was lowered to 0-5°C, and suction filtration was performed. Wash with purified water at 0-5°C until neutral, and dry to obtain a light yellow solid, which is alprazolam intermediate (II), weighed to obtain 12.9g, the yield is 88.5%, and the measured melting point is 114-116 ℃.

[0031] (2) Take 10.0g of intermediate (II) and put it into a three-necked flask, 50ml of ethanol, 4.8g of iron powder, reflux for 0.5h, add dropwise 1ml of sulfuric acid (5mol / L), and reflux for 1h after the dripping, and add NaOH after the reaction is completed Adjust the pH of...

Embodiment 2

[0033] (1) Put 30g of sodium hydroxide solid into 100ml of purified water, lower the temperature to 30°C, put in 10ml of methanol, add 10g of p-nitrochlorobenzene under stirring, react for 0.5h, add 8.2g of phenylacetonitrile dropwise, and complete the dropwise addition in 10 minutes . After the dropwise addition was completed, the temperature was raised to 40° C., and the reaction was carried out for 2 hours. After the reaction was completed, the temperature was lowered to 0-5°C, and suction filtration was performed. Wash with purified water at 0-5°C until neutral, and dry to obtain a light yellow solid, which is alprazolam intermediate (II), weighed to obtain 13.2g, the total yield is 90.5%, and the measured melting point is 114- 117°C.

[0034] (2) Take 10.0g of intermediate (II) and put it into a three-necked flask, 50ml of ethanol, 4.8g of iron powder, reflux for 0.5h, add 1ml of sulfuric acid (6mol / L) dropwise, and reflux for 1h after the dripping, and add NaOH after t...

Embodiment 3

[0036] (1) Put 35g of sodium hydroxide solid into 100ml of purified water, lower the temperature to 30°C, put in 10ml of methanol, add 10g of p-nitrochlorobenzene under stirring, react for 0.5h, add 8.6g of phenylacetonitrile dropwise, and complete the dropwise addition in 15min . After the dropwise addition was completed, the temperature was raised to 40° C., and the reaction was carried out for 2.5 hours. After the reaction was completed, the temperature was lowered to 0-5°C, and suction filtration was performed. Wash with purified water at 0-5°C until neutral, and dry to obtain a light yellow solid, which is the alprazolam intermediate (II). It weighs 13.1 g, the total yield is 89.7%, and the measured melting point is 113- 115°C.

[0037] (2) Take 10.0g of intermediate (II) and put it into a three-necked flask, 50ml of ethanol, 4.8g of iron powder, reflux for 0.5h, add 1ml of sulfuric acid (6.5mol / L) dropwise, and reflux for 1h after the dropwise reaction. After the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com