Preparation method for copper-doped multilayer graphene

A multi-layer graphene, copper-doped technology, applied in the field of graphene, can solve the problems of unfavorable large-scale production and high price of doped graphene, and achieve the effects of being smooth and uniform, low in cost, and easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

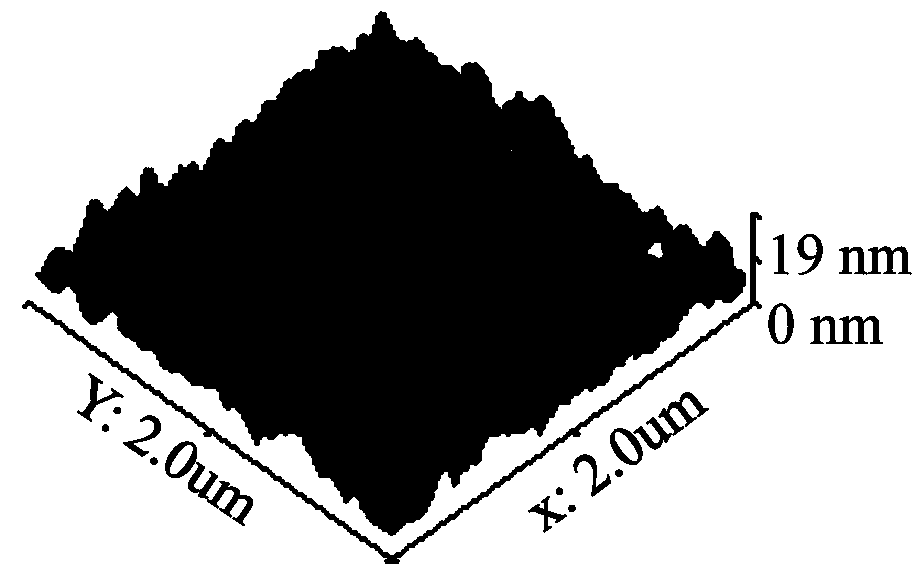

Image

Examples

Embodiment 1

[0022] Embodiment 1: A preparation method of copper-doped multilayer graphene, using graphite target material and copper target material as raw materials, adopting DC and RF co-sputtering in magnetron sputtering, introducing copper element into carbon matrix, making The structure and energy level of multilayer graphene are effectively improved, and the specific steps are as follows:

[0023] 1) Copper targets are placed on the RF, and graphite targets are placed on the DC;

[0024] 2) Pump the vacuum pressure of the cavity to 10 -3 Below Pa, argon gas is introduced, and the pressure of argon is 10~0.1Pa;

[0025] 3) Adjust the radio frequency power to 20W~30W, the DC power to 100W~150W, and sputter together for 30min to obtain thin-film copper-doped multilayer graphene.

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com